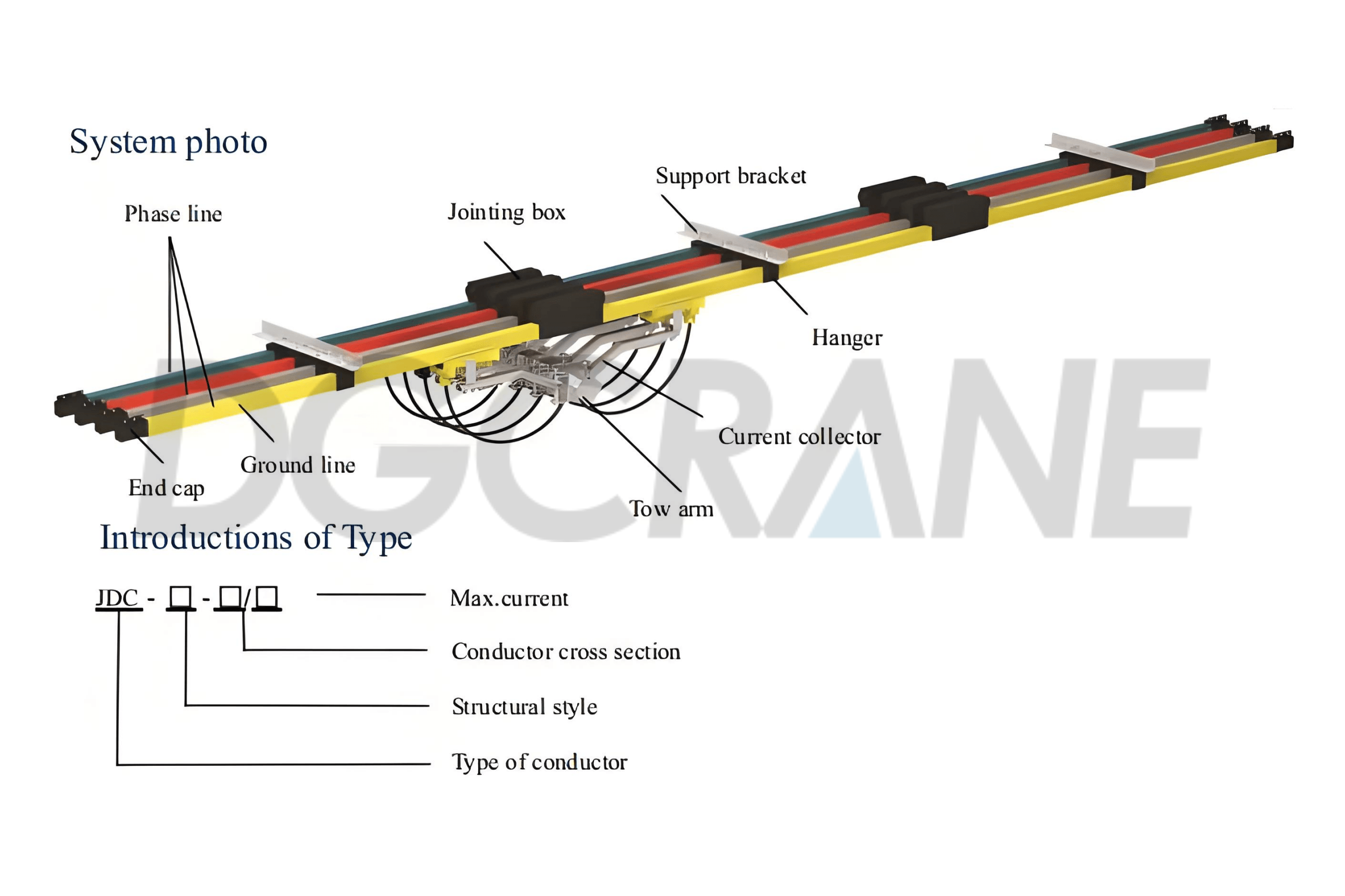

Single-pole Insulated Conductor Rails: Energy-efficient, Safe and Durable

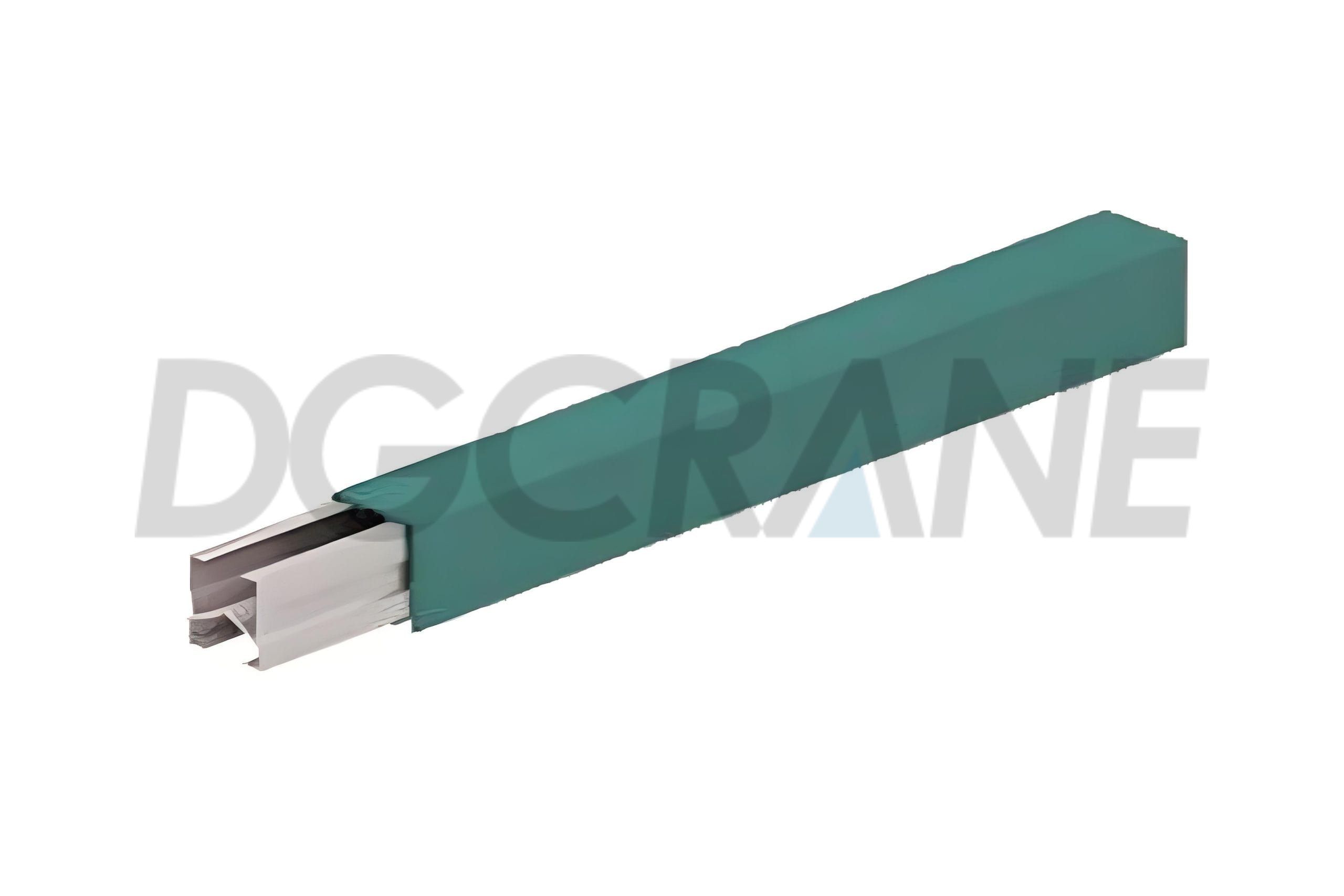

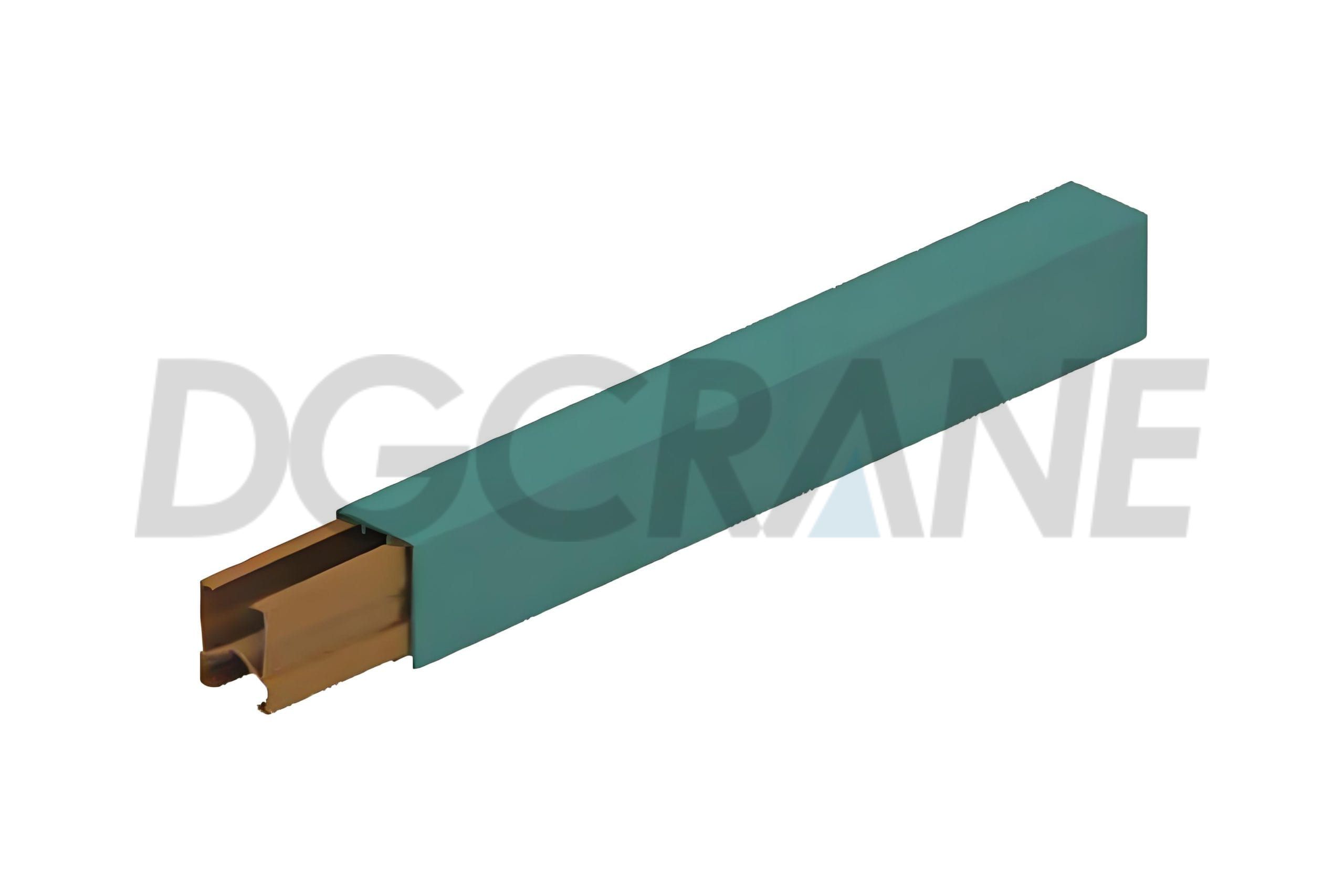

The conductor rails system is a modern supply system using single-pole insulated conductor rails. It complies with the latest regulations and provides electric energy for mobile consumers. The single-pole insulated conductor rails material is copper (200A-5000A), and aluminum (150A-3000). The aluminum conductor rail is provided with a proven and patented stainless steel contact surface. Any number of poles can be installed vertically or horizontally, on straight or curved systems.

The single-pole insulated conductor rails system can be installed indoors or outdoors. For high temperature conditions, a high temperature insulation cover up to +115℃ is available, also for low temperature conditions, it could be up to -40℃.

The entire conductor rail system is insulated from current Safety Regulations, it is entirely protected against direct contact. Ground insulation cover is marked yellow-green on one side over the entire length of the rail.

System photo

Features

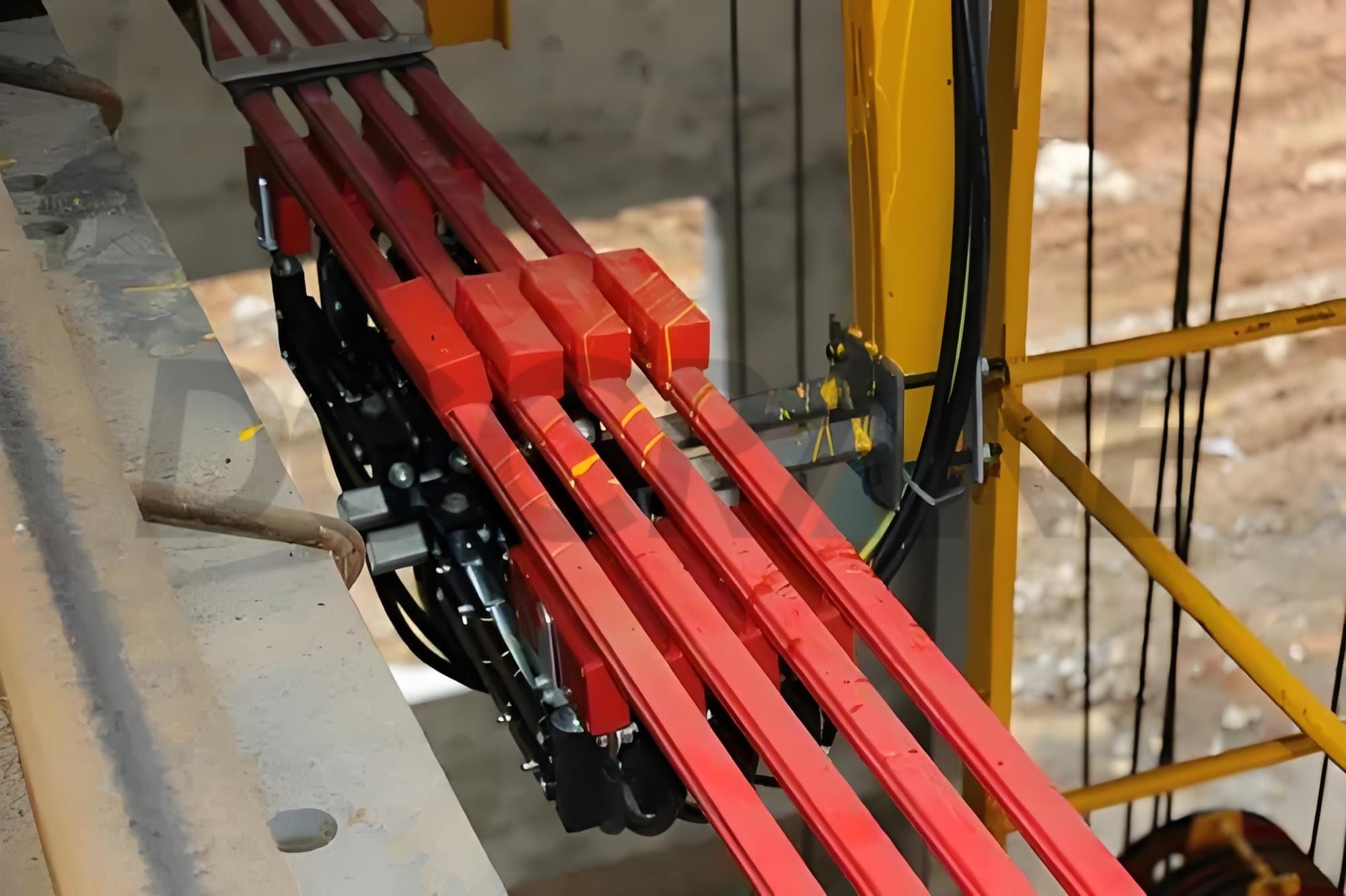

- Safe and Reliable: There is no electric shock risk even when touched by fingers, meeting the IP23 standard.

- Energy-saving: Uses specially formulated aluminum alloy profiles as conductors; with low resistance, it reduces energy loss and improves energy efficiency.

- Long Service Life: The conductor sheath is also made from a unique formulation, greatly extending the service life of the sliding conductor system.

- Three-dimensional Movement of the Collector: The collector can move in three-dimensional space, ensuring an uninterrupted power supply; it uses a double-insulation design for safer and more reliable operation.

- New Materials, Technologies, and Processes: These ensure the product has higher corrosion resistance, weather resistance, and a wider operational temperature range, making it safer and more reliable.

- Modular Design: The product is easy to install and maintain.

Parameters

| Conductor rail system Program JDC-W | |||||||

|---|---|---|---|---|---|---|---|

| Conductor rail | Aluminum | Copper | |||||

| Type | W24 | W32 | W35 | W52 | W24 | W32 | W52 |

| Nominal current at 100%DC and 35℃(A) |

250-300 | 320-1250 | 230-800 | 1250 -3000 | 500 -800 | 800 -1600 | 1250 -5000 |

| D.C.resistance at 35 ℃ (Ω/km) |

0.203 -0.187 | 0.153 -0.046 | 0.153 -0.067 | 0.043 -0.015 | 0.116 -0.067 | 0.067 -0.039 | 0.036 -0.007 |

| Impendance at 35 ℃ (Ω/km) |

0.209 -0.195 | 0.155 -0.048 | 0.155 -0.069 | 0.044 -0.017 | 0.118 -0.069 | 0.069 -0.040 | 0.038 -0.008 |

| Support spacing (m) | 1.5 | 1.8 | 1.8 | 2.0 | 1.5 | 1.8 | 2.0 |

| Rail length (m) | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 | 6.0 |

| Housing length(m) | 5.88 | 5.83 | 5.83 | 5.75 | 5.88 | 5.83 | 5.75 |

| Max.voltage (V) | 690 | ||||||

| Dielectric strength (KV/mm) |

30 -40 | ||||||

| Standard | GB7251.2 -2006 | ||||||

| Traveling speed | ≤600m/min | ||||||

| Expansion joint | Not required up to 200 mins installation length | ||||||

| Flame retardant | Class B1 -no flaming particles, self -extinguishing | ||||||

| Permissible ambient temperature | Standard insulation -20 ℃ -+70 ℃ High temperature insulation -10 ℃ -+115 ℃ Low temperature insulation -40 ℃ -+85 ℃ |

||||||

Material

- Aluminum conductors are suitable for cost-sensitive applications where corrosion resistance is not a particularly high priority, thanks to their lower cost and lighter weight.

- Copper conductors are suitable for environments with high requirements for electrical conductivity and corrosion resistance due to their excellent conductivity and corrosion resistance.

For detailed product information, please refer to the PDF.

Application

In addition, we offer enclosed conductor rails, seamless conductor rails, and copperhead conductor rails to fulfill all your requirements.

Whether you are looking for enhanced durability, superior conductivity, or tailored performance, we are here to provide the ideal solution. Don't hesitate to reach out for a personalized consultation – we're happy to assist you in finding the perfect system for your specific needs.