Mastering Single Girder Overhead Crane Types & Prices: A Complete Overview 2024

The roof position of my factory workshop is low, which single girder overhead crane solution can make full use of the limited upper and lower space?

My factory building is relatively old and the bull’s leg position is designed to be low, which single girder overhead crane solution can maximize the use of the existing space?

My workshop has no load-bearing columns, but the roof is load-bearing, which single girder overhead crane solution is suitable?

What kind of single girder overhead crane solution is available for the working environment which is not suitable for electric equipment?

……

Whether you are in the procurement plan in progress, or are determining the customized scheme of plant lifting equipment, if the lifting capacity requirement is 20ton and below, single girder overhead travelling crane with the advantages of simple structure, flexible scheme and easy dismantling and transportation can be your second choice. And how to choose the right customized program according to your plant is crucial, the following will be from the type of single girder overhead crane, parameter information and price, etc., so that you have a comprehensive understanding of the single girder overhead crane and choose a more suitable program for you.

Types of Single Girder Overhead Cranes

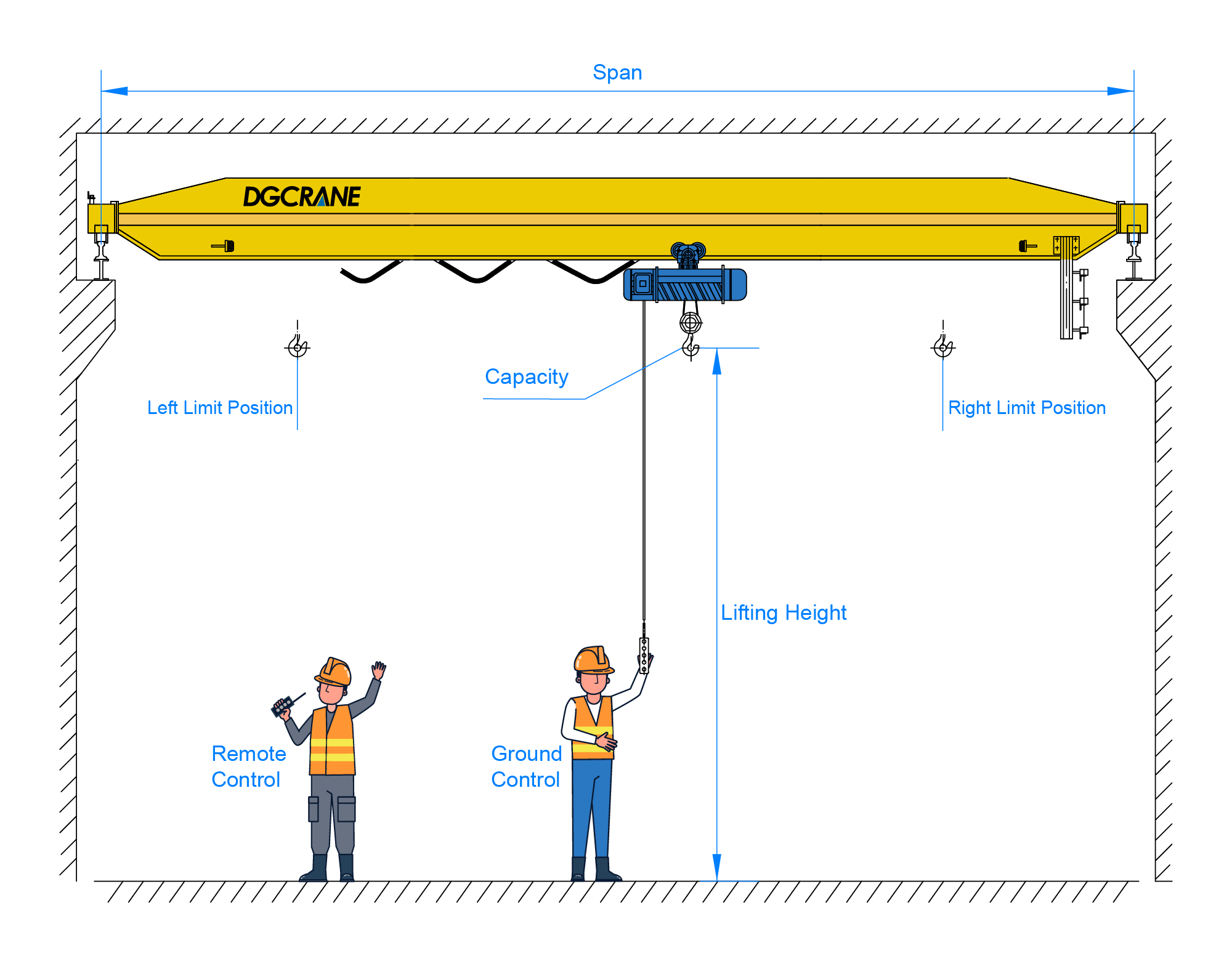

Single Girder Electric Overhead Travelling Crane

The most widely used type of overhead crane, simple structure, easy to install and maintain.

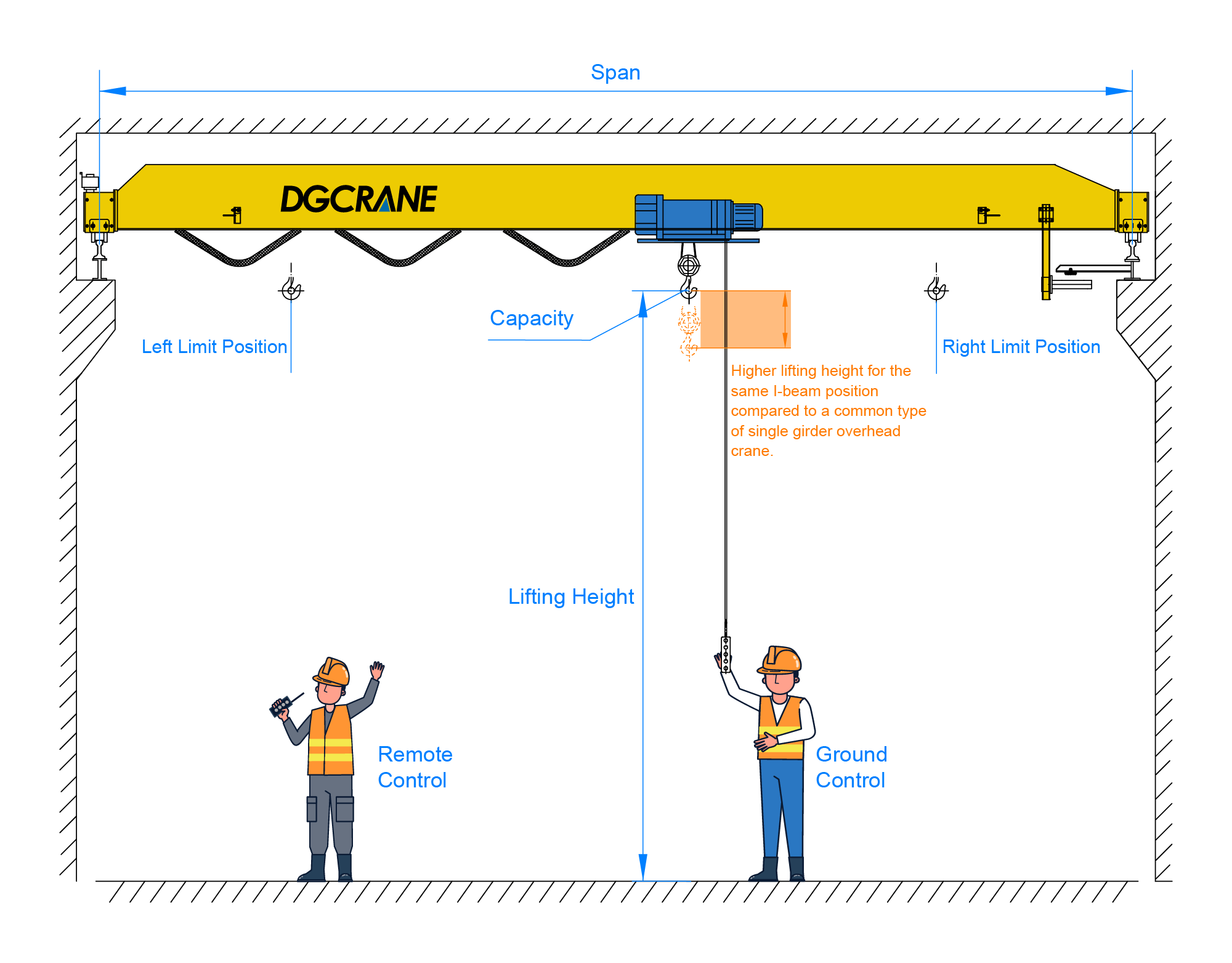

Low Headroom Single Girder Overhead Crane

Compared to the common type of single girder overhead travelling crane, the lifting height can be increased to a greater extent.

Underslung Single Girder Overhead Crane

For plants without load-bearing columns and where the roof is load-bearing.

FEM/DIN Single Girder Overhead Crane

The compact design allows for maximum space utilization, stepless speed regulation, and quiet, maintenance-free operation.

Offset Trolley Single Girder Overhead Crane

The compact design allows for maximum space utilization, stepless speed regulation, and quiet, maintenance-free operation.

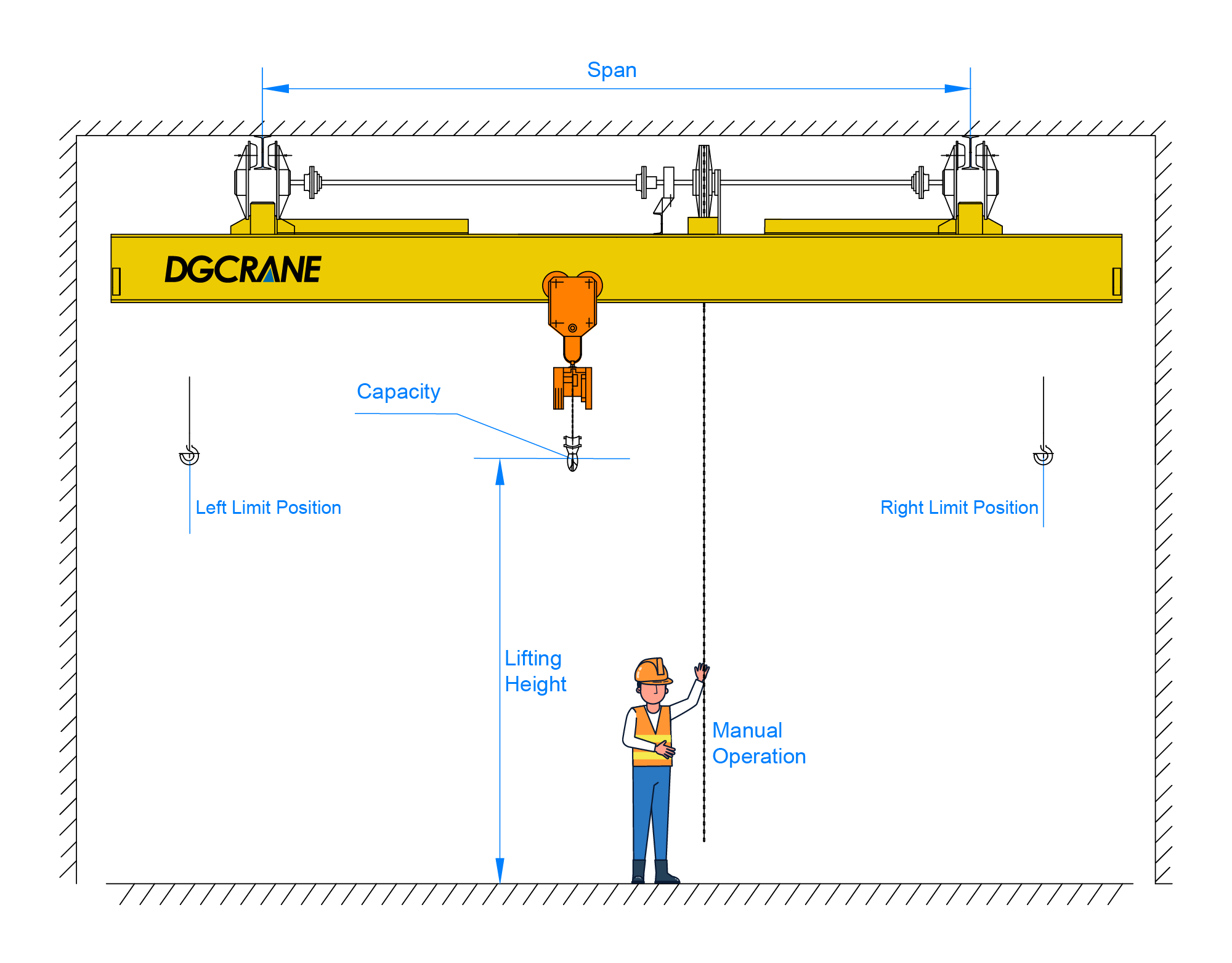

Manual Single Girder Overhead Crane

For use in operating conditions where electrical power systems are not available or cannot be supplied.

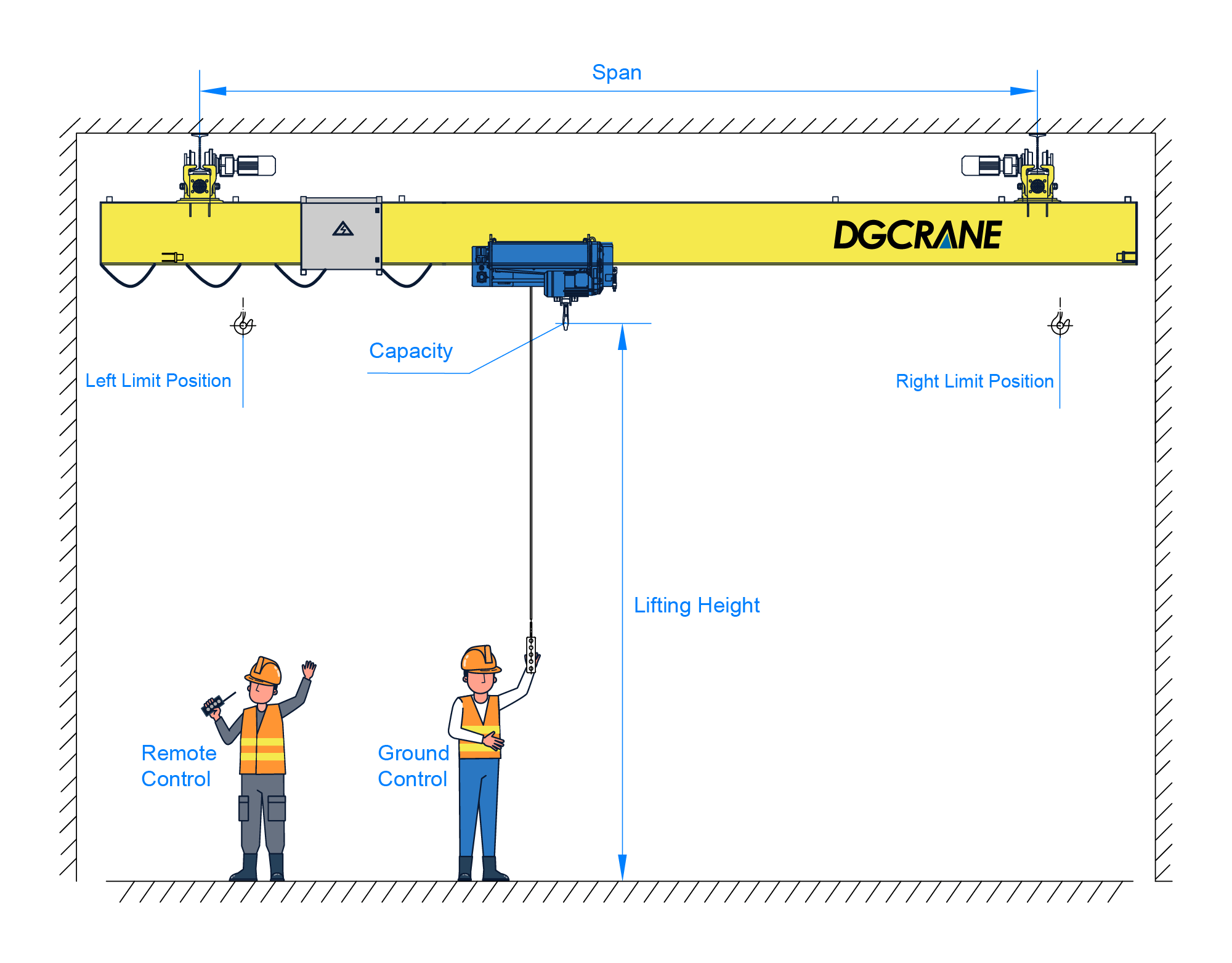

Single Girder Electric Overhead Travelling Crane

Single girder electric overhead travelling cranes-also known as single girder EOT crane or single beam overhead cranes, are our most popular type of overhead cranes, as they provide the most cost-effective lifting solution for all capacities 0.5ton to 20tonnes and upto 31.5mtr span for indoor or outdoor applications.

|

|

Single girder electric overhead travelling cranes are widely used in machining, machine assembly, equipment maintenance and warehouse and other work occasions. They are mainly composed of main beam, end beam, electric hoist, trolley running mechanism, electrical equipment and other parts. Single girder electric overhead cranes have the advantages of compact structure, good rigidity, flexible operation, beautiful modeling, safety and reliability, often used in conjunction with CD1, MD1 electric hoist.

6 sets single girder electric overhead cranes for machining lifting at customer’s plant in China.

Single Girder Electric Overhead Travelling Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $1,830-5,100 |

| 2 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,000-5,900 |

| 3 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,130-7,680 |

| 5 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,130-8,680 |

| 10 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,890-12,000 |

| 16 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $4,180-13,100 |

| 20 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $7,100-18,300 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

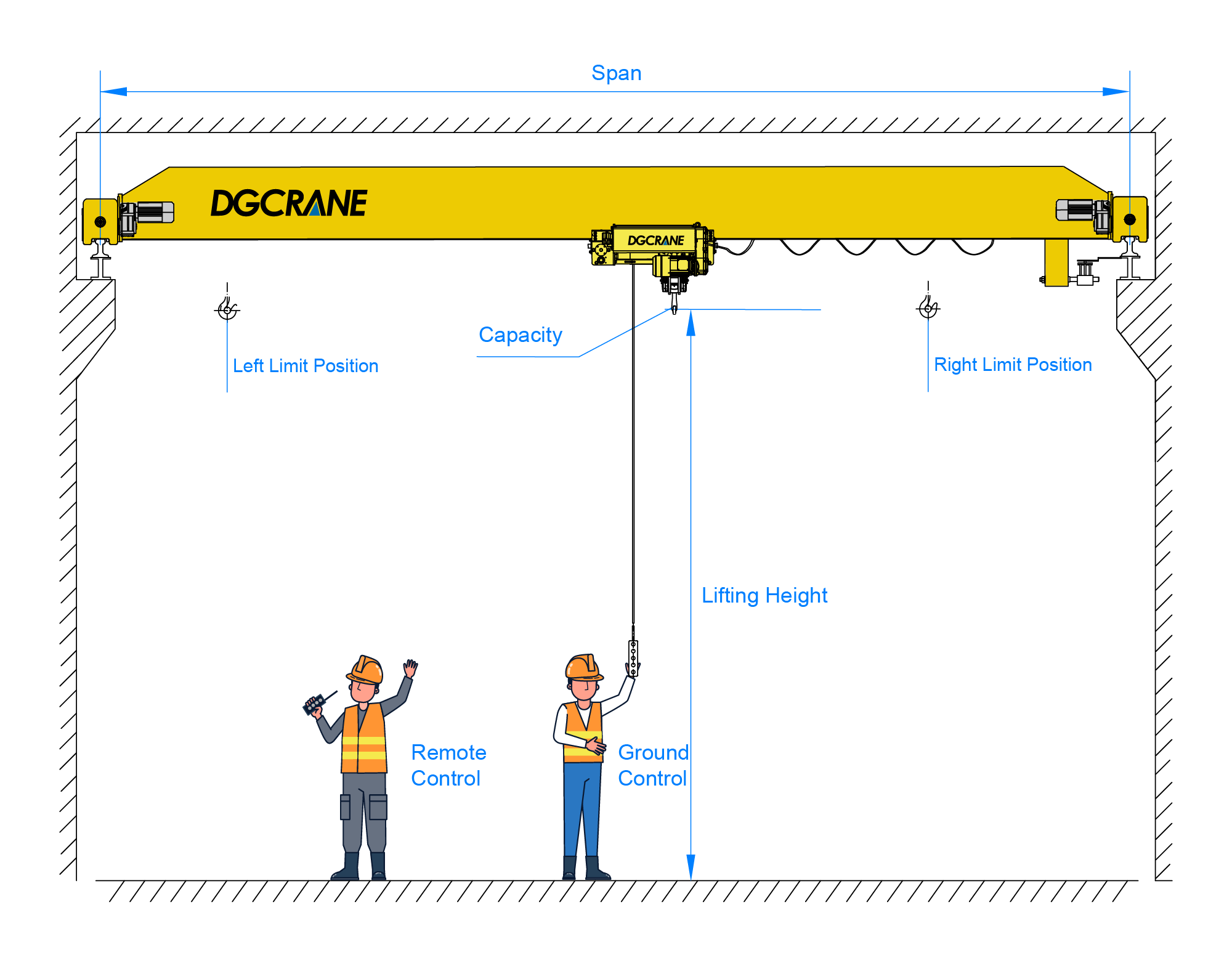

Low Headroom Single Girder Overhead Crane

Low headroom single girder overhead cranes also called low headroom overhead cranes. Compared with common electric overhead travelling cranes, it has better height space utilization. Mainly used in the plant height direction headroom size restrictions, but also need to lift equipment lifting height as far as possible to maximize the situation.

|

|

Low headroom single girder overhead crane is mainly composed of main girder, end girder, low headroom electric hoist, trolley running mechanism, electrical equipment and other parts.

10ton low headroom single girder overhead travelling crane installation at a customer’s factory in Saudi Arabia

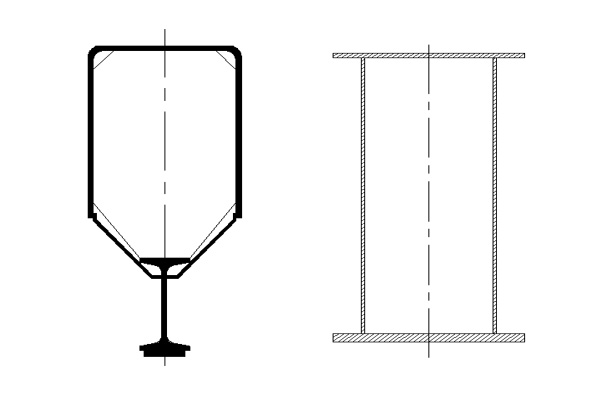

The main girder form of the machine is mostly a square box-type structure, and the wheels of the electric hoist traveling trolley can run back and forth on the lower flange plate of the main girder. Single girder electric overhead travelling cranes hoist trolley is walking on the I-beam flange under the main girder. Other parameters are the same as single girder electric overhead travelling cranes.

Differences in main girder construction betweensingle girder electric overhead cranes and low headroom single girder overhead crane.

Low headroom Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $1,920-5,360 |

| 2 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,100-6,200 |

| 3 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,240-8,100 |

| 5 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,290-9,120 |

| 10 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $4,085-12,600 |

| 16 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $4,400-13,800 |

| 20 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $7,500-19,300 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

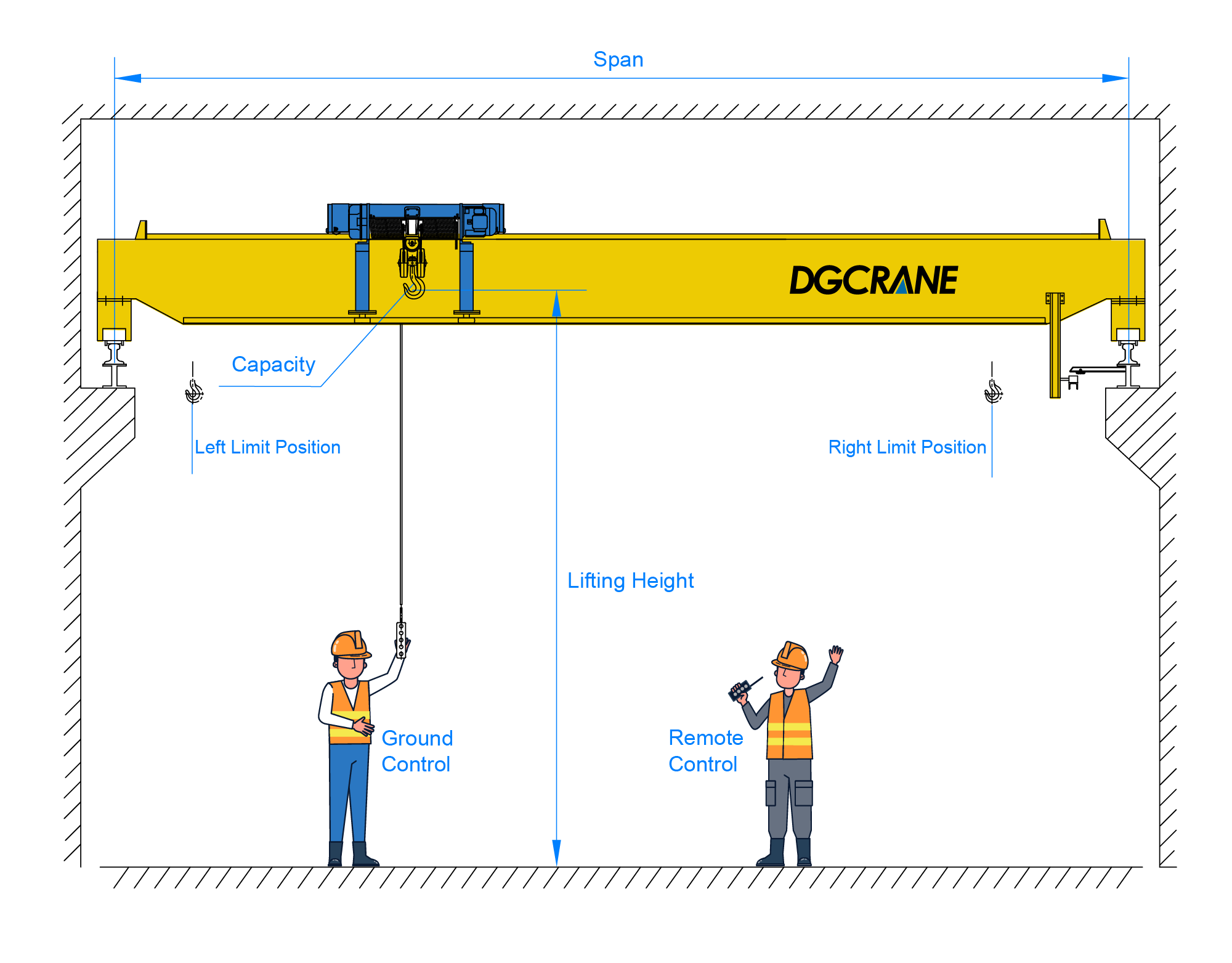

Underslung Single Girder Overhead Crane

Underslung single girder overhead cranes are sometimes called under running crane/single girder underslung crane/under running bridge crane. Commonly used in factory buildings without load-bearing columns, but the roof can be load-bearing.

|

|

Under running cranes in standard capacities up to 10 tons. Special configurations can be designed to accommodate up to 32 tons. Underhung cranes offer excellent side approaches, close headroom and can be supported on runways hung from existing building members if adequate.

5ton Underslung single girder overhead crane on test run in customer’s plant

Underslung Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 3-16 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $1,830-5,100 |

| 2 ton single girder overhead crane | 3-16 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,000-5,900 |

| 3 ton single girder overhead crane | 3-16 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,130-7,680 |

| 5 ton single girder overhead crane | 3-16 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,130-8,680 |

| 10 ton single girder overhead crane | 3-16 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,890-12,000 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

FEM/DIN Single Girder Overhead Crane

The most outstanding feature of FEM/DIN single girder overhead cranes are that the drive mechanism adopts a three-in-one reducer (hardened gear reducer, inverter brake motor), so the structure is also more compact. It is precisely because of this special design that the blind spot range of the overhead crane is smaller in the front and back, so that it can utilize the production area to a greater extent. The brake pads inside the three-in-one gear motor are maintenance-free for life, which can save the maintenance cost in the later stage.

|

|

European standard single girder overhead cranes are widely used in material handling occasions such as workshops and warehouses in machinery manufacturing, petroleum, petrochemical, ports, railways, civil aviation, electricity, food, paper making, building materials, electronics, and other industries. They are especially suitable for material handling that requires precise positioning, precision assembly of large parts and other occasions.

FEM Standard overhead crane successfully installed at customer’s plant in Tanzania

FEM/DIN Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $4,750-8,800 |

| 2 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $4,800-10,380 |

| 3 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $4,980-11,050 |

| 5 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $5,580-12,200 |

| 10 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $7,400-17,300 |

| 16 ton single girder overhead crane | 7.5-28.5 | 6/9/12m or customized | 220V-660V, 50-60Hz, 3ph AC | $11,700-22,800 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

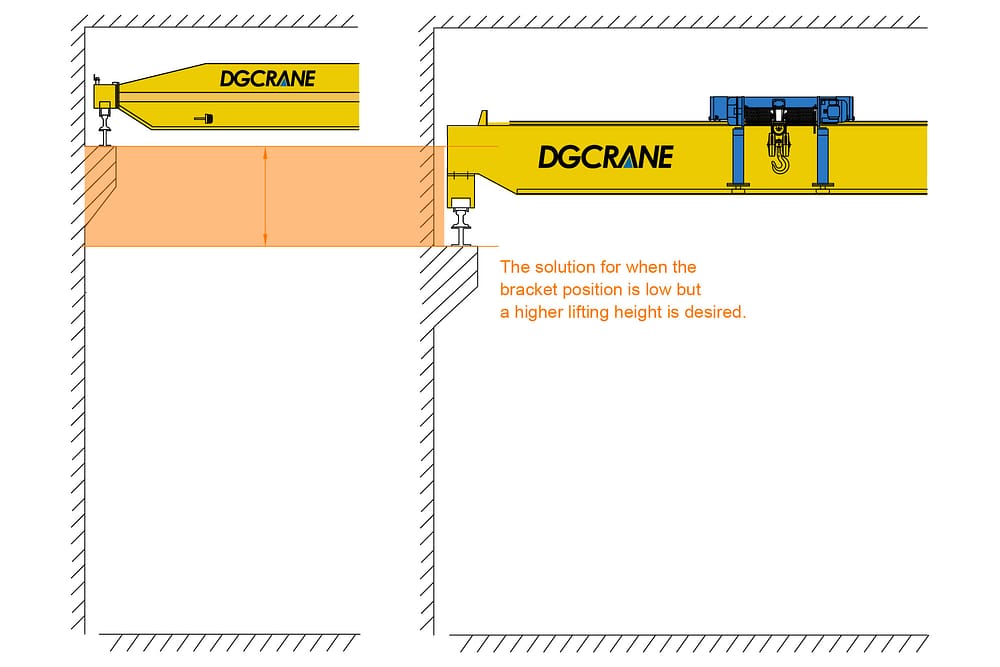

Offset Trolley Single Girder Overhead Crane

Offset trolley single girder overhead cranes are girder cranes with angular trolley structure. It has better height space utilization compared with single girder electric overhead travelling cranes. The structure of the product is often used in the case that the position of the overhead crane in the plant is low, but the headroom height between the top surface of the track and the lowest point of the plant is large. This structure can better utilize the height space inside the workshop and can effectively raise the hoist lifting height.

|

|

Offset trolley single girder overhead cranes mainly consists of main girder, end girder, angle trolley, trolley running mechanism, electrical equipment and other parts. All other parameters are the same as single girder electric overhead travelling cranes type.

Offset trolley single girder overhead cranes are suitable forsituations where the bracket position is low but a higher lifting height is required.

Offset single girder overhead cranes at customer’s plant in China.

Offset Trolley Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $2,930-9,180 |

| 2 ton single girder overhead crane | 7.5-28.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,200-5,220 |

| 3 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $3,400-13,800 |

| 5 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $5,000-15,600 |

| 10 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $6,220-2,1600 |

| 16 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $6,680-23,500 |

| 20 ton single girder overhead crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $11,360-32,940 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

Manual Single Girder Overhead Crane

Manual single girder overhead cranes are also divided into top running type and two different types of under running, are suitable for the use of places where the equipment can not be provided with power. Its structure is reasonable and compact, easy to transport, easy to install, simple and flexible operation, is a common small and light lifting equipment.

|

|

Manual Single Girder Overhead Cranes are often used for installation and maintenance of equipment, such as sewage treatment plants/cement plants/wind turbine rooms/coal bunkers in thermal power plants / hydroelectric projects.

DGCRANE’s Manual Single Girder Overhead Cranes Shipped to Pakistan

Manual Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton single girder overhead crane | 4-12 | 3m/6m/9m upto10m | Manual Mode | $840-1,800 |

| 2 ton single girder overhead crane | 4-12 | 3m/6m/9m upto10m | Manual Mode | $880-1,900 |

| 3 ton single girder overhead crane | 4-12 | 3m/6m/9m upto10m | Manual Mode | $930-2,000 |

| 5 ton single girder overhead crane | 4-12 | 3m/6m/9m upto10m | Manual Mode | $1,600-3,060 |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

No the type of overhead crane you’re looking for?

Provide information about your need to your dedicated customer service now!

Or leave your information for our service team.No current demand, but would like to get a new price list.

Prices will be updated from time to time, If you want to get the latest price list the first time, leave your email, and we will send it out for you as soon as possible.

FAQs

Top running cranes and underhung cranes are two types of overhead cranes that are distinguished by the way move along their runway systems.

Top Running Cranes

Type: Single girder electric overhead travelling cranes / Low headroom single girder overhead cranes/ FEM single girder overhead cranes / Offset single girder overhead cranes / Manual Single Girder Overhead Cranes(top running ytpe) / most type of double girder overhead cranes

Applications: Top running cranes are commonly used in industrial settings, manufacturing facilities, and warehouses where heavy loads need to be lifted and transported across a large area. Compared to underhung cranes, top-running cranes are typically larger and a better choice for higher capacity lifting applications, such as those involving 10 tons or more.

Advantages:

- Can handle heavier loads.

- Suitable for longer spans.

- Generally more stable.

- Easier installation and wide availability of parts.

Under Running Cranes

Type: Underslung single girder overhead cranes / Underslung double girder overhead cranes / Manual Single Girder Overhead Crane(under running type)

Applications: Underhung cranes used in factory buildings without load-bearing columns, but the roof can be load-bearing.

Advantages:

- Ideal for facilities with limited headroom.

- Can be more cost-effective in certain situations.

In summary, the main difference between top running and underhung cranes lies in how they are supported and move along their runways. Top running cranes run on the top of the runway beams, while underhung cranes run underneath the runway beams. The choice between these two types of cranes depends on factors such as the available space, load capacity requirements, and the specific needs of the application.

You need to determine from which angle your plan favors more consideration:

- You want to save more money

- Maximize space utilization

- To maximize space utilization and minimize maintenance.

You may focus on one or more of these aspects, but the most important thing is to customize a solution that is more suitable for you in terms of the actual situation of your plant. DGCRANE has a lot of experience in customizing single girder overhead travelling cranes, such as this example, where we have helped our customer to customize a single girder overhead travelling crane solution that fully meets their needs, and has received a very positive feedback.

Therefore, it is important to choose a professional supplier with a lot of experience in customization!

Choosing the right single girder overhead crane supplier is crucial to ensure that you get a reliable and high-quality product. Here are some steps to guide you in selecting the right manufacturer:

Evaluate Experience and Expertise

- Consider the manufacturer’s experience in the industry. More experienced manufacturers often have a better understanding of customer needs and industry trends.

- Evaluate their expertise in designing and manufacturing single girder overhead cranes.

Review Product Range - Examine the range of products offered by the manufacturer. Ensure they have a variety of single girder overhead cranes suitable for different applications and industries.

- Check for customization options to meet specific requirements.

Request References and Case Studies

- Ask the manufacturer for references from previous clients. Contact these references to gather insights into their experiences with the manufacturer.

- Look for case studies or success stories related to the manufacturer’s products.

Visit Manufacturing Facilities

- If possible, visit the manufacturer’s facilities to assess their production capabilities, quality control measures, and overall manufacturing processes.

- A well-organized and modern facility is an indication of a reliable manufacturer.

Consider After-Sales Support

- Evaluate the after-sales support provided by the manufacturer. This includes maintenance services, spare parts availability, and technical support.

- Choose a manufacturer with a responsive customer service team.

Compare Pricing and Terms - Request detailed quotations from multiple manufacturers for the specific type of single girder overhead crane you need.

- Compare not only the pricing but also the terms, warranty, and payment conditions.

DGCRANE not only meets the above conditions, but also has 10+ years of rich experience in foreign trade exports. Contact your exclusive customer service now!

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!