Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

Shipyard gantry cranes is primarily used for transporting large ship structures, installing ship equipment, moving raw materials, and assembling or repairing ships. It can handle oversized and heavy objects, playing a crucial role in ensuring efficient and safe operations in shipbuilding and maintenance processes.

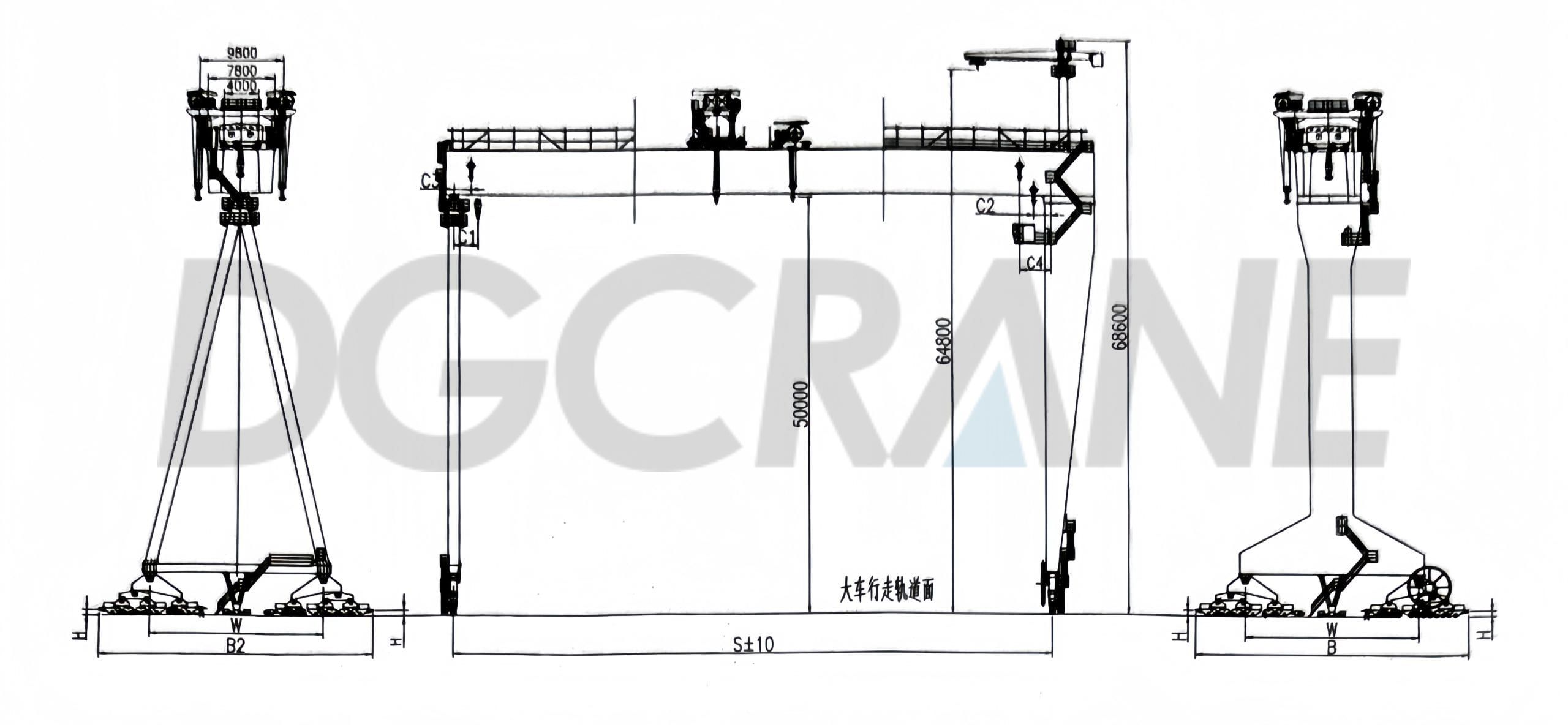

Due to the large span of shipbuilding gantry cranes, the gantry typically uses a design with one rigid leg and one flexible leg. The rigid leg is rigidly connected to the main beam, while the flexible leg is connected to the main beam via a flexible hinge.

Shipyard gantry cranes usually have two trolleys, upper and lower. The upper and lower trolleys travel on their respective tracks, with the lower trolley capable of passing beneath the upper trolley. Additionally, there is a horizontal trolley that moves horizontally along the main beam track.

Features

- It has multiple functions including single lifting, tandem lifting, aerial turnover, and horizontal micro-rotation in the air.

- The gantry offers two types for users to choose from: single-girder and double-girder. To optimize material usage, the main beam is designed with variable cross-sections.

- The rigid leg of the gantry has two options: single-column and double-column.

- The upper trolley is equipped with double main hooks located on either side of the main beam, which can move laterally independently or simultaneously by 0-2 meters.

- The lower trolley has both main and auxiliary hooks positioned beneath the center of the main beam.

- The upper and lower trolleys can pass each other during operations.

- All lifting and running mechanisms use variable frequency speed regulation.

- On the rigid leg side, a jib crane is installed on top of the main beam for maintenance of the upper and lower trolleys.

- For the convenience of operators and maintenance personnel, an elevator is installed inside the rigid leg.

- To prevent damage from strong winds, reliable wind-proof devices such as rail clamps, ground anchors, and anchor chains are installed.

Parameters

| Lifting capacity | Upper trolley | t | 75X2 |

| Lower trolley | 100 | ||

| Servicing Crane | 5 | ||

| Two trolleys lifting | 200 | ||

| Section reverse pointing | 150 | ||

| Span | m | 70000 | |

| Lifting Height | trolley | 50000 | |

| Servicing Crane | 65000 | ||

| Duty | A5 | ||

| Speed | Lifting speed | m/min | 0.5~5~10 |

| 0.5~5~10 | |||

| 10 | |||

| Trolley Traveling | 2.5~20~40 | ||

| 2.5~20~40 | |||

| 10 | |||

| Crane Traveling | 2.5~25 | ||

| Limit dimension | C1 | mm | 4000 |

| C2 | 3500 | ||

| C3 | 3500 | ||

| C4 | 4000 | ||

| Main dimension | H | mm | 650 |

| B | 31510 | ||

| W | 20000 | ||

| Max.Wheel Loading | kN | 336 | |

| Total Power | kW | 519 | |

| Crane Rail Recommended | QU80 | ||

| Power Supply | 3-Phase A.C,50Hz 10KV | ||

Case

Built to handle large spans, heavy loads, and special requirements, shipyard gantry cranes offer practical, reliable, and efficient solutions for the shipbuilding environment.

DGCRANE can customize crane solutions according to your needs, just tell me your specifications and our technical team will provide you with the most professional solutions.