Semi Gantry Cranes

Compared with the overhead crane, it saves the workshop space occupied by pillars; Compared with the gantry crane, it saves the production space; One side is support leg, the other side is end carraige as overhead crane, making better use of the plant structure. It is one cost-effective crane solution!

- Capacity: 2t-40t

- Span length: 15-30m

- Lifting height: 6m, 9m, 12m,etc.

- Work duty: A3-A6

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -25℃~+40℃, relative humidity ≤85%

- Crane control mode: Pendant control / Wireless remote control / Cabin control

- Reference Price Range: $6000-100000/set

Overview

Semi-type gantry cranes (BMH type, BMG type) are used with CD1, MD1, other types of electric hoist or LH hoist trolley or QD trolley. It is suitable for lifting, transporting, loading and unloading in open-air operation sites such as stations, wharves, warehouses, construction sites, cement product yards, machinery or structural assembly yards, power stations, etc. It is also suitable for working in indoor workshops.

The support legs of the semi-gantry crane have a height difference, which can be determined according to the civil construction requirements of the use site.

It is composed of lifting mechanism and trolley, single main beam (or double main beam) , support leg, and end carraige, electric control box, operating system, and safety protection system, etc.

Advantages

- Compact Structure

- Good Rigidity

- Safety and Reliablity

- Easy Operation

- Covenient Installation

- Easy Transportation

Introduction

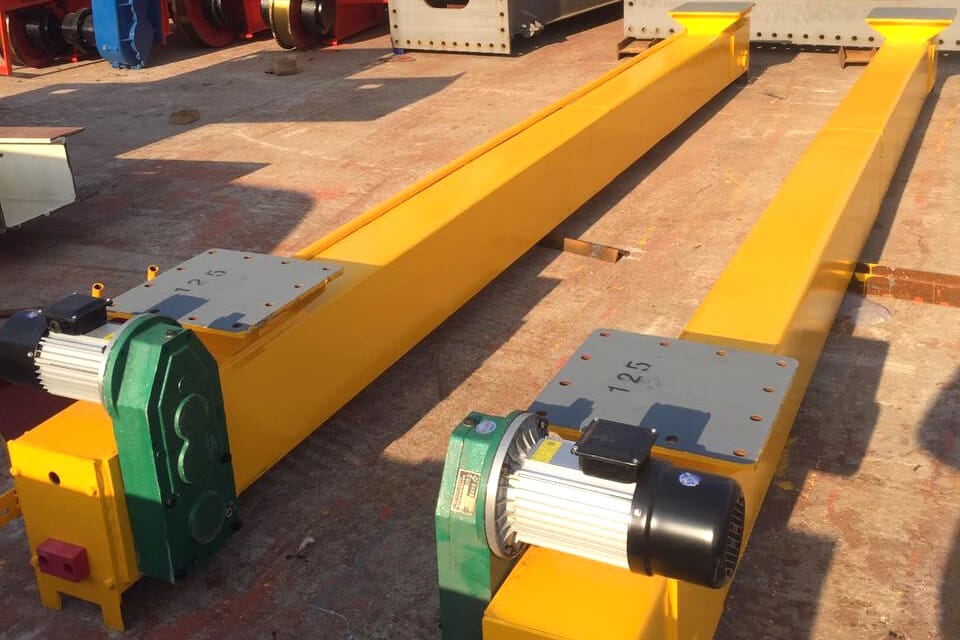

Semi gantry crane is a special form of Gantry Crane. Just as shown in the picture, at one side of the crane, this gantry crane for sale runs on an elevated runway system like a overhead crane along the length of the factory.

At the other side, it just runs like a standard rail mounted gantry crane. This special overhead gantry crane for sale allow you extend your workplace by not needing a runway system from the top of the building.

Compared with gantry crane, it uses the structure of the plant instead of a new leg of the crane itself. Undoubtedly, it owns a more cost effective. Considered that semi gantry crane doesn’t depend entirely on the plant, this special structure gantry crane has an advantage on the flexibility over EOT crane.

There are two typical applications:

Indoors, it is often used under the existing overhead cranes to provide more hooks, thus improving the the productivity of your factory.

Outdoors, often is used near the building, making full use of the existing runway structure, thus improving the cost efficient of your factory or plant.

Depending on the loading capacity, this special kind gantry crane can be formed in single girder gantry cranes, as well as double girder gantry crane. So, if you want to see more technical parameters, you can just get a reference from corresponding Overhead Cranes or Gantry Cranes.

Components

The main beam is the crane's main load-bearing component, and the running track for the electric hoist. It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam. The main beam is made into an upper arch according to the requirements, and the upper arch F should be (1/1000~1.4/1000)S. The two sides of the span are designed with saddles connected to the outriggers, and there are rectangular steel plate connecting flanges. There are buffers at both ends of the main beam to ensure the safe operation of the trolley on the main beam.

The end beam is located at one end of the main beam and is fixed on the main beam with bolts through flange plates. It is a box-shaped structure consisting of a U-shaped groove, a lower cover plate, a reinforcing plate and a rib formed by rolling or welding steel plates. The end beam has the characteristics of light structure, good rigidity, beautiful appearance, and good welding performance. There are buffers, and long travel limit, such protective devices.

It is a triangular beam is weld by a support frame(welded by angle steel and other section steel) and an I-beam.

The A-shaped structure increases the strength, rigidity and stability of the gantry frame. The steel plate flange between the leg and the ground beam is connected by bolts. The structure is simple, the installation is convenient, and it is convenient for transportation and storage.

The lower beam is also a box-shaped structure, mainly composed of cover plates, webs, ribs, flange supports and other parts. The production process is similar to that of the main beam and other box beams. After the lower beam structure is completed, the bent plates are assembled according to the drawing. The flange support is welded to the lower beam after the lower beam is made to ensure the level of the flange surface. When the lower beam and the leg are assembled, the flange on the flange made on the leg is welded to the leg.

The appearance quality and geometric dimensions of the lower crossbeam after production meet the requirements of the standard GB14406-93.

Single girder gantry crane can use chain hoist, wire rope hoist, low headroom hoist, and European style hoist;

Double girder gantry crane can use LH hoist trolley, NLH European style hoist trolley, integrated hoist, and QD trolley.

The crane traveling mechanism is driven separately, mainly composed of: operating motor, operating reducer, wheel set, etc. The motor adopts a soft-start motor, with its own brake, and the brake is reliable; The reducer adopts vertical gearbox to save space; LDA-type wheels, double-wheel edges, are not prone to wheel climbing and falling off.

The hoist power supply is the cable type, and the slideway can use wire rope slideway, I-steel slideway, and special-shaped steel slideway;

The crane powersupply can be powered by a cable drum, buss bar, etc.

Can use control handle with pendant line, wireless remote control, or cabin control.

Phase failure protection, fire limit, crane travel limit, heavy hammer limit-lifting height limit, overload limit, etc.

A Standard Semi Gantry Cranes Will Be Produced in 30 Days.

Incoming material sample inspection

Steel plate uncoiling, leveling and cutting

Fabrication of the gantry crane- main beam

Fabrication of the gantry crane- end beam

Fabrication of the gantry crane-ground beam

Fabrication of the gantry crane-support leg

Crane preassembly

Electrical conrol unit assembly

Painting and storage

Tips:

Lead time of cranes with different voltage may be 10-15 days longer as electrical components need to be customized by our supplier.On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.