FEM Standard Overhead Cranes

European type overhead crane is independently developed and designed based on the advanced European design and manufacturing technology, combined with the latest domestic standards.

The appearance is beautiful, and the driving mechanism adopts a three-in-one reducer (hard tooth surface reducer, frequency conversion brake motor), which is completely comparable to similar European products in terms of appearance and technical performance.

- Capacity: 3.2-80ton

- Span length: 4-31.5m

- Lifting height:customized according to clients' site conditions

- Work duty: A5

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Protection class: IP54 IP55

- Crane control mode: Pendantcontrol / Remote control / Cabin control

Overview

European type overhead/bridge cranes are widely used in material handling occasions such as workshops and warehouses in machinery manufacturing, petroleum, petrochemical, ports, railways, civil aviation, electricity, food, paper making, building materials, electronics, and other industries. They are especially suitable for material handling that requires precise positioning. , Precision assembly of large parts and other occasions.

Its superior performance is embodied in the mature application of modular design, frequency conversion speed regulation, automatic detection, and other advanced technologies. The complete protection functions such as overload protection, over current protection, and loss of voltage protection make the crane application and working performance more perfect.

Advantages

- Compact structure

- Good rigidity

- Easy operation

- Low noise

- Save plant space and investment costs

- Safety and reliability

- Beautiful appearance

Protection Devices of European Type Overhead Cranes

- Frequency converter: The protection function of the inverter can protect the short-circuit, over-current, motor overheating, under-voltage, over-voltage, grounding, short-circuit, stall prevention, heat sink overheating, and braking unit overheating protection of each driving mechanism.

- Distribution protection: The main circuit of crane power distribution is equipped with protective components such as an automatic air switch for the main power supply and main contactor.

- Short circuit protection: The main power circuit is equipped with an automatic switch as short-circuit protection of the crane; the control circuit is equipped with a small-capacity automatic air switch as short-circuit protection.

- Overload protection: The motors of each mechanism of the crane are equipped with separate overcurrent protection devices as the overload protection; the automatic air switch of the main power supply is used as the overload protection of the crane.

- Phase sequence protection: The equipment adopts a phase sequence protector to monitor the quality of the power supply in real time. When the power supply generates overvoltage, undervoltage, phase loss, or phase sequence change due to external reasons, the control system will cut off the main circuit to effectively protect the safety of equipment and personnel.

- Lift limit protection: The lifting mechanism is equipped with in-position limit switches and limit switches. The in-position limit switches ensure that the lifting mechanism stops automatically when it is in place. The limit switches can ensure that the lifting mechanism automatically cuts off when the hook up to the limit position.

- Travel limit protection: The crane traveling and trolley traversing mechanisms are generally equipped with in-position limit switches and limit switches at both ends.

- Emergency power off protection: The control circuit of the crane is equipped with an emergency switch. When an accident occurs, the power supply of the control circuit can be cut off at any time, and then the main circuit is cut off to ensure the safe operation of the crane.

- Anticorrosion, dustproof and sealing measures.

Introduction

Widely used in warehouse and factory, overhead cranes for sale are an important material handling equipment. While, different country and region have their own features.

In China, the original overhead crane and manufacturing technology is originate from the former Soviet Union. After decades of development, the overhead crane appears to be like now, and has been applied nearly all domains in China, which has demonstrated its Excellent Properties.

So if you are from Russian, this will be very familiar to you. Other wise, if your from European and American area, thing will be different. Next, let us talk about the European style overhead cranes for sale.

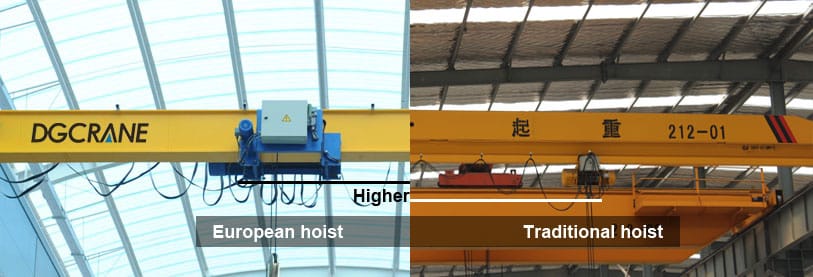

To tell the truth, overhead cranes for sale are used more widely in the world, except in China, of course. There are many difference between them in appearance and in technical standards. While, as the development and the communication of the technology, the different is smaller and smaller, especially in double girder overhead cranes. Now, the main difference is in single girder overhead crane and the mounted electric wire rope hoist. Just as shown in the following picture:

Cross girder – The European type single girder overhead cranes for sale is the H shaped steel structure, while the traditional type single girder overhead crane is the welded box type. The European type has a lighter weight.

End trucks – There is no big difference in the end trucks.

Hoists – Another main difference is the hoist, the European type hoist is more advanced and has a higher lifting height.

Brief Technical Parameters Comparison

| Technical data | Traditional type | European type |

|---|---|---|

| Capacity | to 16 mt | to 12.5 mt |

| Span | to 90‘ | to 98′ |

| Bridge travel speed | to 98 fpm | to 160 fpm |

| Trolley travel speed | to 65 fpm | to 100 fpm |

| Hoist speed | to 26 fpm | to 41 fpm |

Details Specifications On Request

| ITEMS | TRADITIONAL STYLE OVERHEAD CRANE | EUROPEAN TYPE OVERHEAD CRANE |

|---|---|---|

| Structure and function | Simple | Sophistacated and mutifunctional |

| Price | Much more costs efficient | Expensive |

| Crane net weight | More heavy witha higher energy costsa higher construction cost | Lighter steel structure andmore efficient in energy costsmore efficient in construction costs |

| Adaptive capacity | More robustin servere working conditions andenen in improper operations | Stable and comfortablebut requires a proper working condition anda proper operation |

Which Is Better

Generally speaking, the European type overhead crane is more advanced and better. While, regarding the working condition, operating condition and the price, I know that Suitable is the best. In DGCRANE, it is our honour offering the suitable crane for your, with our different type of overhead cranes, and the flexible sale plan.

Components

The main girder is a welded box structure, and the lower flange plate is the hoist running track. The main beam is manufactured in strict accordance with the process flow. The welding adopts a fully automatic CO2 shielded welding production line, which has small welding deformation, high welding seam strength and low residual stress. The welds are inspected according to the national standard GB3323. It has better strength, stiffness and stability

The crane end carriages adopts a rectangular tube integral end beam structure to avoid deformation caused by welding. The large-scale floor boring machine is used for processing and shaping at one time to ensure that the two deflection values of the wheel are within the tolerance range. The improved design of the crane end beam reduces the vertical rigidity and increases the horizontal rigidity, which can overcome the phenomenon that the three wheels of the crane wheel touch the ground and greatly increase the life of the wheel. The end beam structure for installing the wheels incorporates international advanced technology, and adopts an integral boring structure, which has higher installation accuracy.

The lifting mechanism adopts European type hoist or European type trolley.The hoist lifting mechanism adopts planetary gear, which is compact and light, and is installed in the reel, effectively reducing the size of the electric hoist. Its design adopts modular design to the greatest extent, and its parts are highly versatile. The design standard adopts the European FEM standard, and the selection of parameters such as lifting speed and running speed is more humane. The design has a slow speed and accurate positioning, suitable for installation and maintenance; the design has a fast speed, which makes the lifting mechanism more efficient and more convenient.

The crane traveling mechanism adopts the “three-in-one” driving gear motor, which drives the two end beams on both sides; the electric motor, adopts the special brake motor for the crane and is connected by bolts. This drive type has high transmission accuracy, light weight, good sealing, low noise, long life, and maintenance-free advantages.

The voltage of the European type overhead crane is determined by the customer’s local industrial voltage, and the electrical system is manufactured according to the voltage. Equipped with a cross fork rotary limit switch, cut off the power of the traversing motor and long traveling motors before the crane buffer collides with the track end block. Equipped with an overload limiter. When the wire rope tension is greater than 90% of the rated value, the overload protection device will alarm. When the wire rope tension is greater than 110% of the rated value, the overload protection device will automatically cut off the hoisting circuit. The power supply of the trolley adopts special-shaped steel suspension with flat cable.

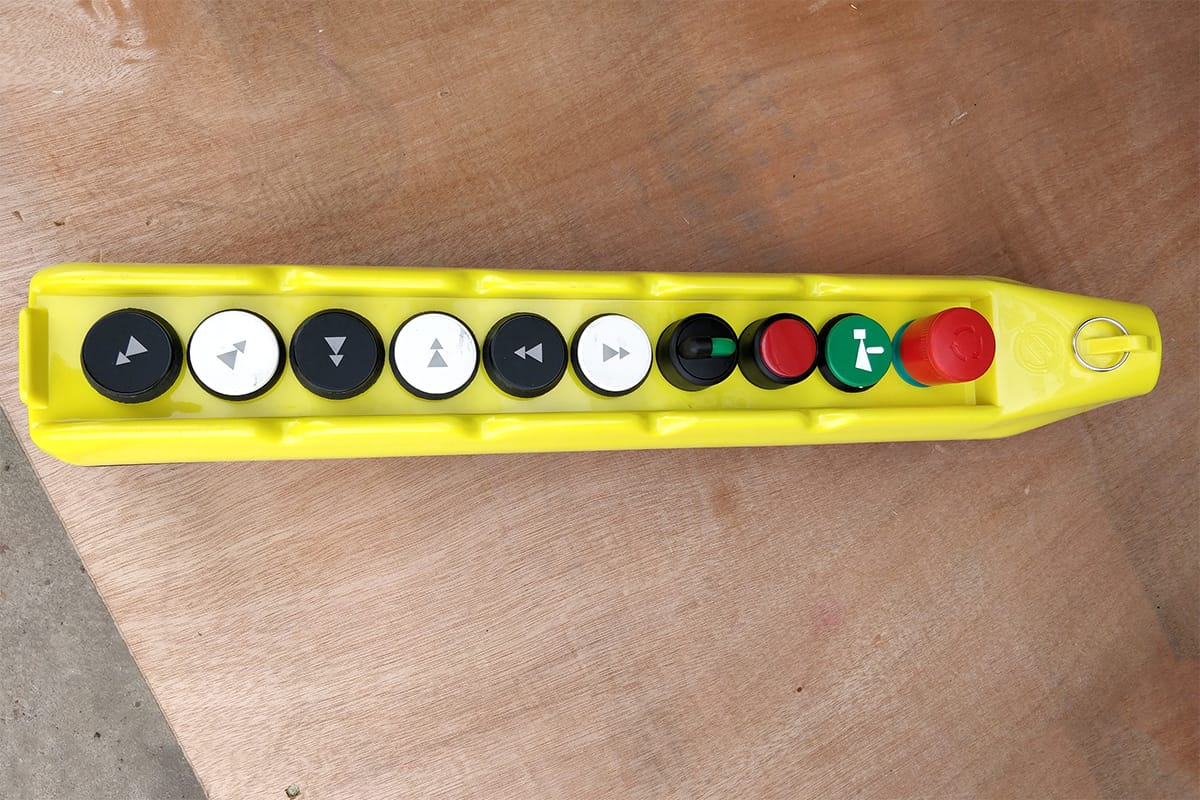

Pendant panel, Remote control, Cabin control. The crane can also be equipped with two sets of operating devices, namely: ground + remote control or driver’s cab + remote control. However, due to safety issues, the two operating modes can only be switched and cannot be used at the same time.

- Frequency converter: The protection function of the inverter can protect the short-circuit, over-current, motor overheating, under-voltage, over-voltage, grounding, short-circuit, stall prevention, heat sink overheating, and braking unit overheating protection of each driving mechanism.

- Distribution protection: The main circuit of crane power distribution is equipped with protective components such as an automatic air switch for the main power supply and main contactor.

- Short circuit protection: The main power circuit is equipped with an automatic switch as short-circuit protection of the crane; the control circuit is equipped with a small-capacity automatic air switch as short-circuit protection.

- Overload protection: The motors of each mechanism of the crane are equipped with separate overcurrent protection devices as the overload protection; the automatic air switch of the main power supply is used as the overload protection of the crane.

- Phase sequence protection: The equipment adopts a phase sequence protector to monitor the quality of the power supply in real time. When the power supply generates overvoltage, undervoltage, phase loss, or phase sequence change due to external reasons, the control system will cut off the main circuit to effectively protect the safety of equipment and personnel.

- Lift limit protection: The lifting mechanism is equipped with in-position limit switches and limit switches. The in-position limit switches ensure that the lifting mechanism stops automatically when it is in place. The limit switches can ensure that the lifting mechanism automatically cuts off when the hook up to the limit position.

- Travel limit protection: The crane traveling and trolley traversing mechanisms are generally equipped with in-position limit switches and limit switches at both ends

- Emergency power off protection: The control circuit of the crane is equipped with an emergency switch. When an accident occurs, the power supply of the control circuit can be cut off at any time, and then the main circuit is cut off to ensure the safe operation of the crane.

- Anticorrosion, dustproof and sealing measures

A European Type Overhead Crane Will Be Produced in 45 Days

Incoming Material Sample Test

Steel plate uncoiling and falttening

Steel sheeting cuttig

Rolling groove

Welding-the-main-girder

Crane pre assembling

Assembly-of-the-European-type-wire-rope-hoists

Crane packing and delivery

Tips:

Lead time of cranes with different voltage may be 10-15 days longer as electrical components need to be customized by our supplier.Types of Cranes for Different Working Conditions

HD European type single girder overhead crane

- Reliability, Efficient, Easy Operation, Safety

- Low Procurement And Maintenance costs

- Usually the max lifting capacity of the HD European type single girder overhead crane is 12.5ton

NLH European type double girder overhead crane

- Reliability, Efficient, Easy Operation, Safety

- Low Procurement And Maintenance costs

- When the capacity is bigger than 12.5ton, it is suggested customer choose NLH European type double girder overhead crane

QD European type double girder overhead crane

- Beautiful appearance and light structure

- Environmentally friendly and silent

- Technical advantages: dual-speed intelligent frequency conversion

- Stable lifting

On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.