Why I Choose Jib cranes for my industry?

Industrial cranes are essential equipment in numerous industries such as manufacturing, construction, logistics, and warehouses. They are designed to handle heavy loads, streamline operations, and improve workplace safety. By efficiently lifting and moving materials, industrial cranes enhance productivity and reduce the risk of accidents associated with manual handling.

3 Main Types of Industrial Cranes

- Overhead Cranes: Overhead cranes are widely used in large-scale industrial settings where heavy loads need to be transported across expansive areas. They are classified into different types based on their structural features and lifting capacity.

- Gantry Crane: A gantry crane is a versatile overhead crane that utilizes legs or supports on wheels. This design allows for easy movement along a rail system, making it ideal for outdoor applications such as shipyards and construction sites.

- Jib Cranes: Jib cranes are a specialized type of industrial crane that consists of a horizontal arm (jib) mounted to a vertical mast or wall. These cranes provide a high level of maneuverability and are suitable for localized lifting and material handling tasks.

Are your workers struggling to meet the production quotas? Do you find that a significant amount of time is consumed during the final stages of work completion? Are you looking for ways to streamline your company’s production process and alleviate the burden of repetitive tasks for your workers?

Jib Crane may be your ultimate solution to all these challenges!

Industrial Jib Cranes

Jib cranes are commonly used in workshops, manufacturing plants, warehouses, construction sites, and other industrial settings. Industrial Jib Cranes can be classified into five main types: Free-standing Jib Cranes, Wall-mounted Jib Cranes, Wall-travelling Jib Cranes, Balance Jib Cranes, and Articulating Jib Cranes.

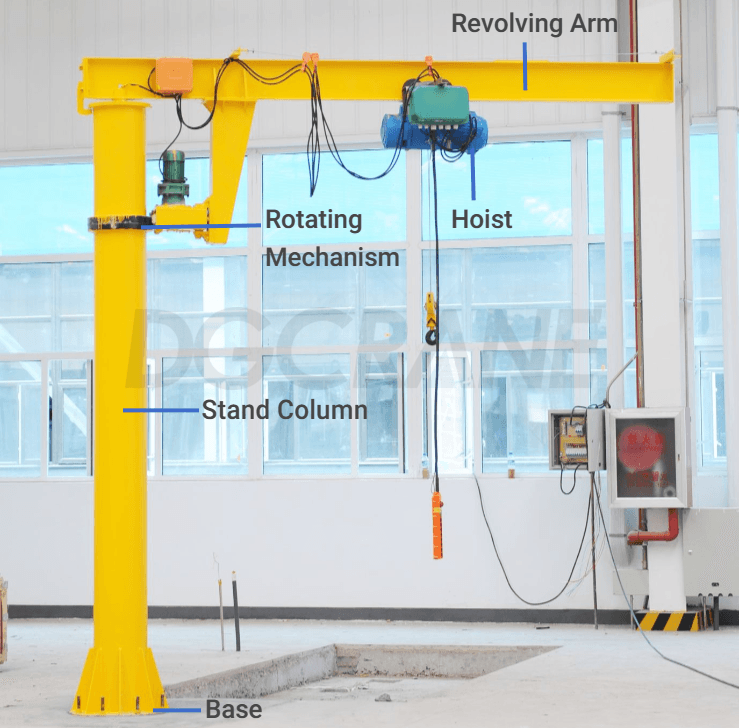

Components of Jib Cranes

Jib cranes typically consist of the following components:

- Revolving Arm: The horizontal beam responsible for carrying the load.

- Stand Column or Wall Mount: The vertical support structure that holds the jib arm.

- Hoist or Lifting Mechanism: The device used to raise and lower the load.

- Rotation Mechanism: Allows the jib arm to rotate horizontally.

- Foundation: Provides stability and support for the crane.

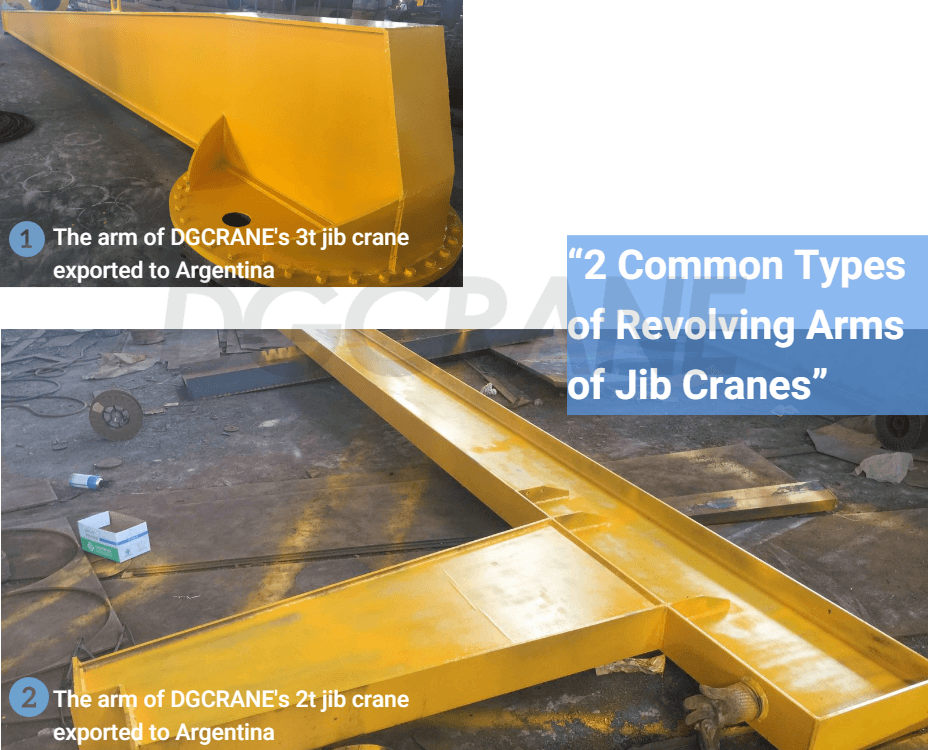

DGCRANE’s Jib Cranes Exported to Argentina

DGCRANE’s Jib Cranes Exported to Argentina

The construction of jib cranes ensures durability, reliability, and ease of operation, making them suitable for a wide range of industrial applications. We also have a comprehensive guide to jib crane installation for you.

Unveiling the Advantages of Jib Cranes

- Ergonomic Design and Simplicity: One of the key reasons behind the popularity of jib cranes is their ergonomic design and user-friendly nature. These cranes are intuitively designed, ensuring easy comprehension and hassle-free operation for workers. With minimal training required, your workforce can quickly adapt to using jib cranes, minimizing downtime and maximizing productivity.

- Complementary Use with Overhead Cranes: Jib cranes can seamlessly integrate with overhead cranes, further enhancing their productivity-boosting capabilities. By combining the lifting power of a jib crane with the expansive reach of an overhead crane, you can efficiently handle a wide range of lifting tasks, optimizing your workflow and reducing production time.

- Low Maintenance and High-Volume Handling: In addition to their impressive performance, jib cranes require minimal maintenance, allowing you to focus on core production activities. These cranes are built to withstand high-volume lifts, ensuring reliable and consistent performance over extended periods. With fewer parts to maintain, jib cranes minimize the risk of downtime and keep your production process running smoothly.

- Ease of Operation: Operating a jib crane is a breeze, thanks to its straightforward design and intuitive controls. With fewer components involved, your workers can easily operate the crane, carrying out tasks with efficiency and precision. By eliminating complex procedures, jib cranes empower your workforce, enabling them to accomplish more in less time and with reduced effort.

Optimize Your Production Process with Jib Cranes

To improve the efficiency of your production process, minimize downtime, and enhance overall productivity, incorporating jib cranes into your operations is a wise choice. By harnessing the power of these versatile lifting devices, you can empower your workers, streamline your workflow, and meet your production quotas with ease. Don’t let repetitive tasks burden your workers or hinder your company’s growth. Invest in jib cranes today and unlock the full potential of your production capabilities!

Conclusion

In conclusion, industrial cranes play a vital role in facilitating efficient material handling and lifting operations in diverse industries. Among the various types of industrial cranes, jib cranes offer flexibility, versatility, and space-saving advantages. The different variations of industrial jib cranes, including free-standing, wall-mounted, wall-traveling, balance, and articulating, cater to specific lifting needs. Their robust construction, combined with ease of operation and cost-effectiveness, makes them a preferred choice for many industrial applications.

At DGCRANE, we produce top-quality and exceptionally made industrial cranes well suited to your requirements. Our expert team can help design light-duty ergonomically cranes suitable to production and budgetary needs. To get more information, check out our Homepage and Contact Us now! We are willing to offer your advice and make a tailor-made solution for you!

FAQs

- Q: What is the maximum lifting capacity of jib cranes?

A: The lifting capacity of jib cranes varies depending on the specific model and design. They can range from a few hundred kilograms to several tons. - Q: Are jib cranes suitable for outdoor use?

A: Yes, certain types of jib cranes, such as free-standing jib cranes, can be installed outdoors. However, weather conditions and other environmental factors should be taken into consideration. - Q: Can jib cranes be customized for specific lifting requirements?

A: Yes, jib cranes can be customized with various lifting attachments, such as hooks, grabs, or magnets, to accommodate specific lifting needs. - Q: What safety measures should be followed when operating jib cranes?

A: It is essential to follow proper safety guidelines, including regular inspection, operator training, and adherence to load capacity limits, to ensure safe operation of jib cranes. - Q: Can jib cranes be used in cleanroom environments?

A: Yes, balance jib cranes are commonly used in cleanroom environments where delicate material handling is required.