Selecting Crane Wireless Remote Control: Find Your Perfect Match in 2025

Table of Contents

Crane Wireless Remote Control Types for Workplace Scenarios

The choice of which type of operation type of crane wireless remote control must be combined with different working requirements and environmental conditions to determine.

- Conventional workshop use scenarios, such as lifting equipment for lifting small and light workpieces, it is appropriate to choose the button type remote control, simple operation, flexible, and lightweight.

- Equipment to achieve more functions, and more control points, suitable for the choice of joystick remote control, such as metal smelting workshop, sand mold casting workshop, precision machinery assembly workshop, chemical raw materials, blending, transfer workshop, and other places need to lift molten liquid metal lifting equipment.

- When using flammable and explosive hazardous media in the environment, in order to ensure the safe and stable operation of the equipment, to avoid and prevent the occurrence of production accidents, one should choose an explosion-proof environment with a special remote control. Such as lifting equipment used in the following places: chemical plants, gas plants, cement plants, flour mills, coal mines, and other places.

It should be noted that if you need to use frequency control, stator voltage control, or speed control of lifting equipment, suitable for the choice of rocker remote control, is especially suitable for use in infinitely variable speed control equipment.

Pushbutton Crane Wireless Remote Controls

F21-2D transmitter and receiver

F21-4S/4D transmitter and receiver

F21-E1/E2 transmitter and receiver

F21-E1B transmitter and receiver

F23-BB transmitter and receiver

F24-8S transmitter and receiver

F26-A1 transmitter and receiver

F26-A2 transmitter and receiver

F26-A3 transmitter and receiver

F26-B1 transmitter and receiver

F26-B2 transmitter and receiver

Joystick Crane Wireless Remote Controls

F24-60 transmitter and receiver

Crane Wireless Remote Controls for Explosion-proof

How to Choose the Right Wireless Remote Control for Your Crane

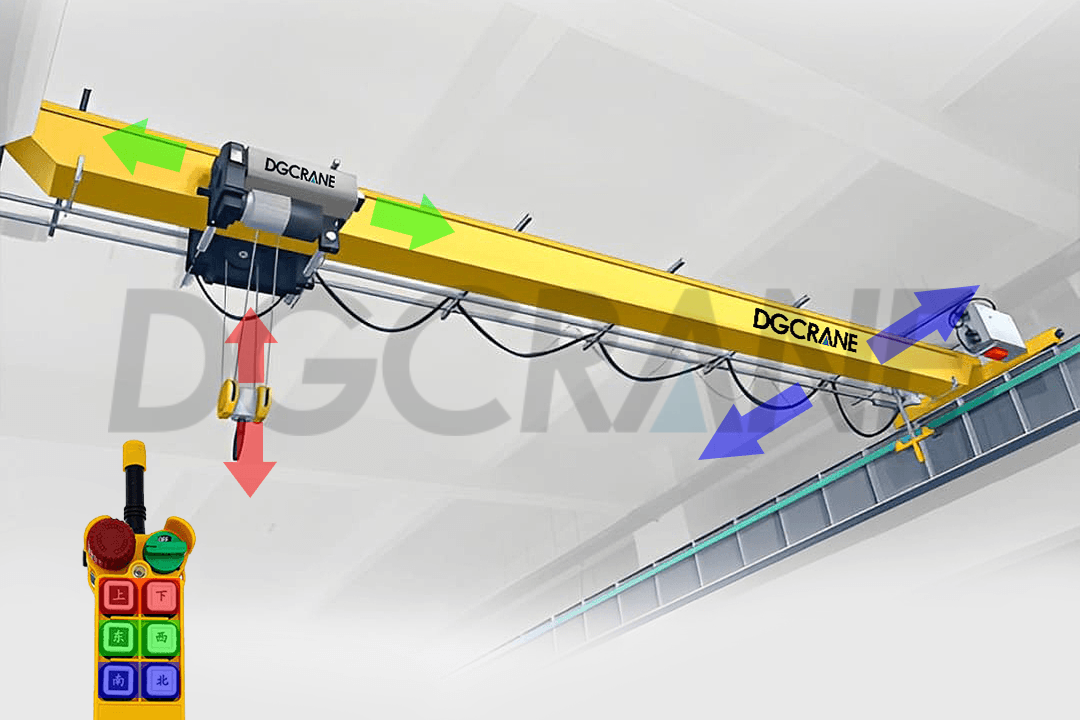

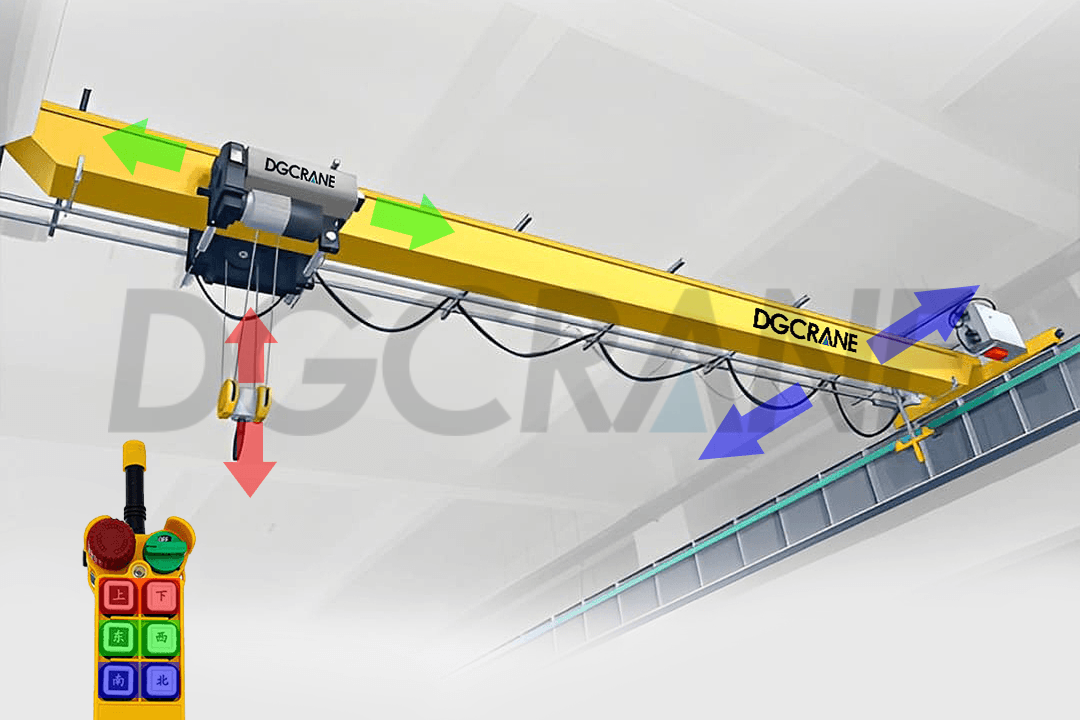

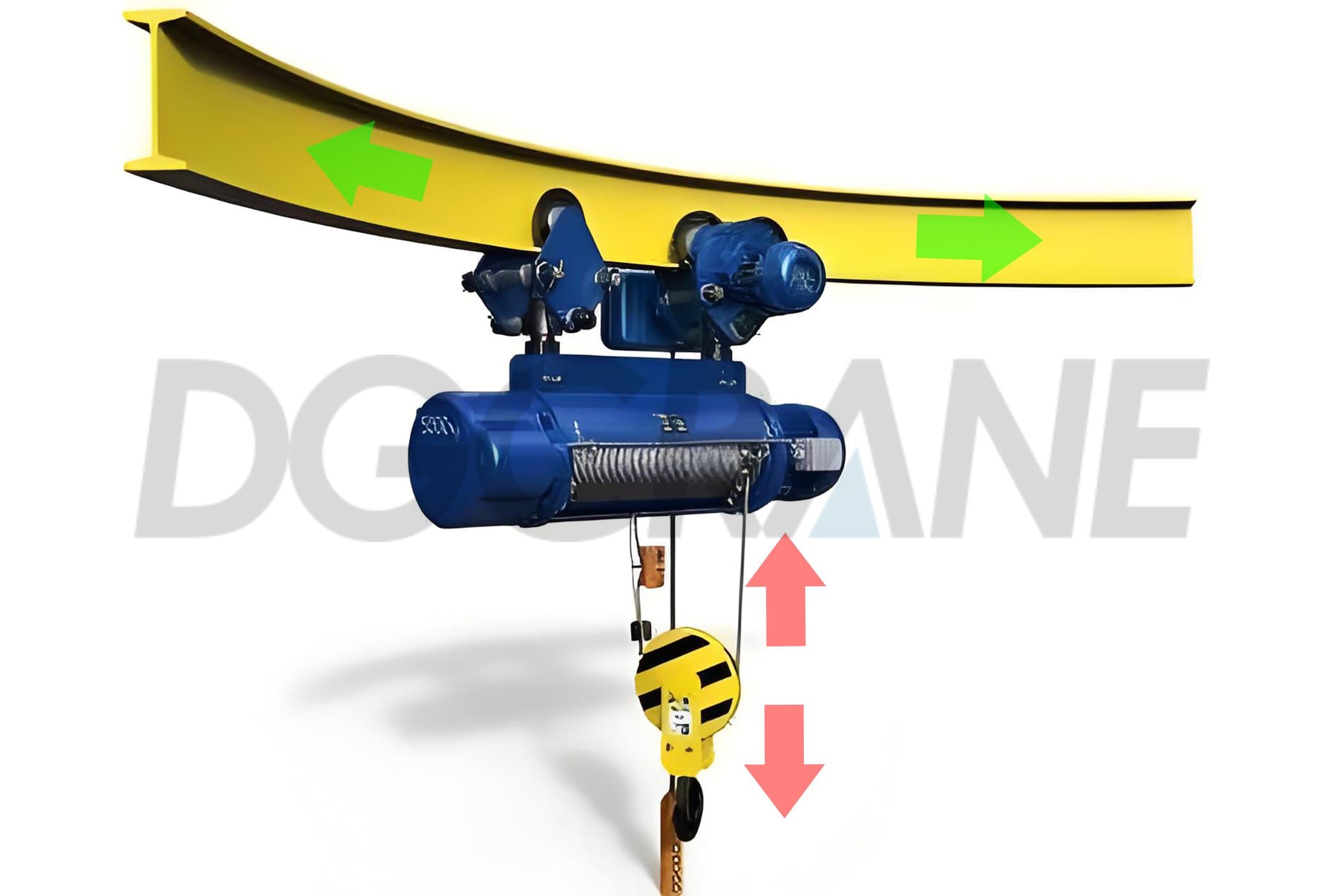

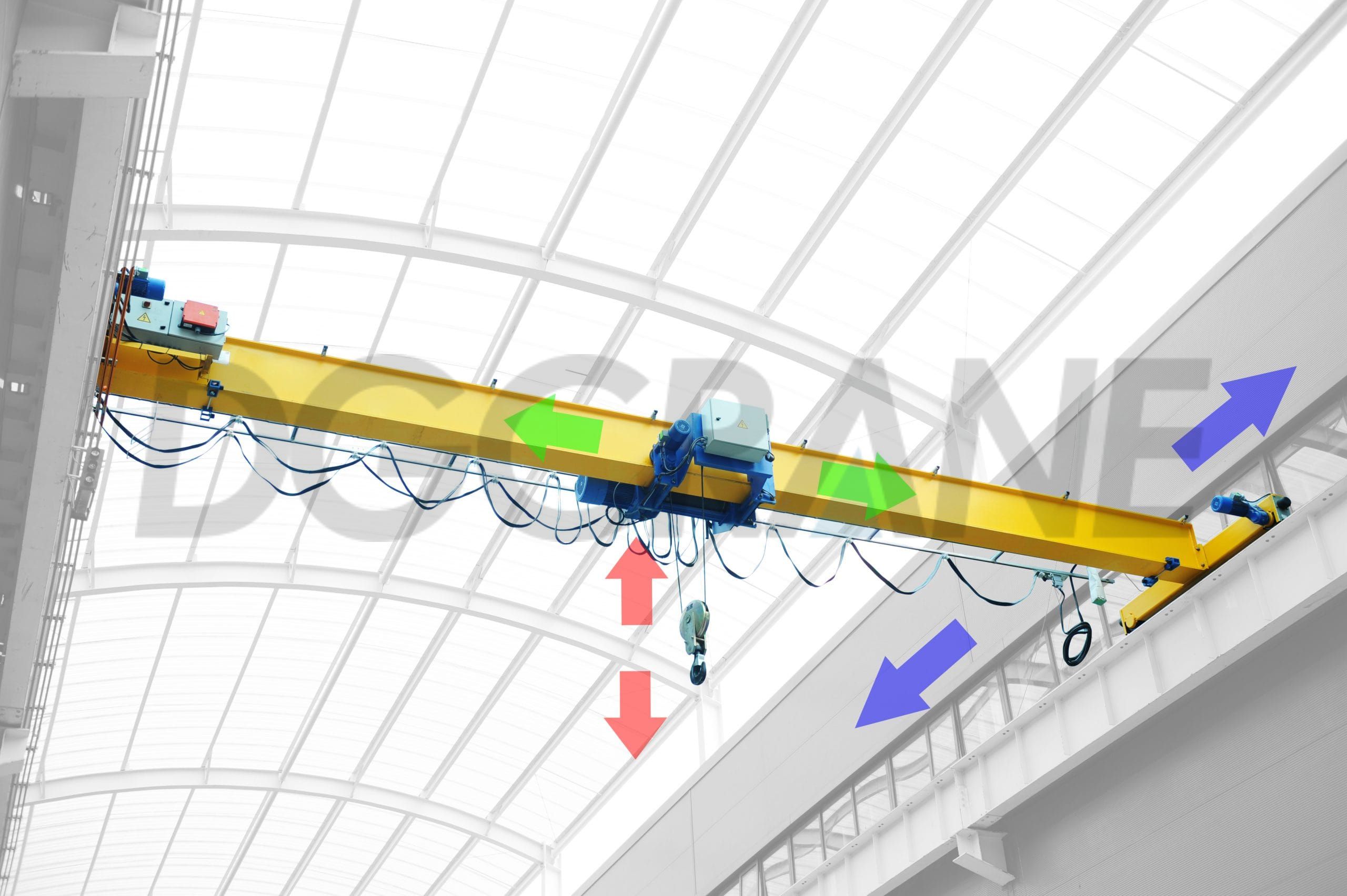

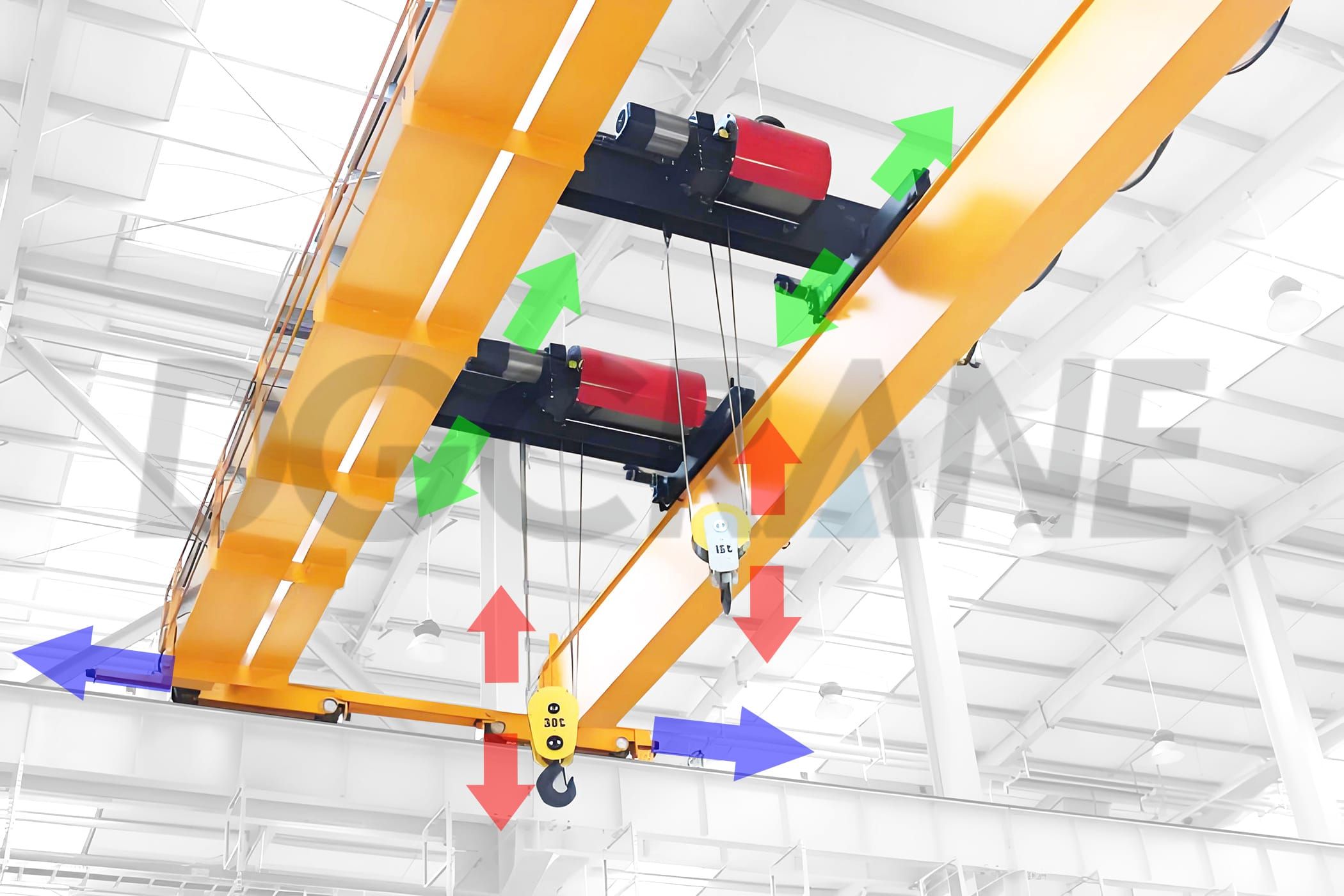

Crane wireless remote control can realize remote control of crane lifting mechanism lifting and lowering, traveling trolley left and right movement, crane whole machine forward and backward movement or rotation, and other operations. There are things to consider when choosing the right lifting and hoisting equipment for you.

- Type and specification of crane: According to the type (bridge crane/gantry crane/jib crane, etc.) and specification (e.g., lifting capacity, span, working radius, etc.) of the crane, different types and specifications of cranes have different requirements for wireless remote control.

- Control functions: understand the control functions of the wireless remote control, such as lifting, moving left and right, rotating, etc., and whether to support the simultaneous control of multiple cranes. Button crane wireless remote control of the number of buttons and control functions are closely related.

- Effective working distance: the effective working distance of the transmitter and receiver, push-button wireless remote control is generally about 100 meters, can be customized to 200 meters, rocker type wireless remote control can reach 300 meters.

- Crystal remote control vs. card remote control:

• Signal transmission mode: The crystal type is analog signal transmission, key type is digital signal transmission.

• Anti-jamming ability: Crystal-type anti-jamming ability is strong, the signal is more stable, and the card type is relatively poor.

• Remote control pairing: crystal type pairing is more troublesome, plug-in type is convenient and flexible.

• Cost-effective: Crystal-type performance is more stable, and the price is higher. The plug-in type price is relatively low, and the general use of the scene is more commonly used.

The following will help you understand how to choose the most suitable wireless remote control solution for your crane through the following several usage environments and our case studies.

Consider Button Count for Crane Wireless Remote Control Functions

Fixed electric hoists

Just move up and down

F21-2S/F21-2D Transmitter

When only the operation of lifting equipment up and down in two directions is required, the wireless remote control model F21-2S/F21-2D can be selected.

- For fixed CD-type single-speed electric hoist hoists, select the F21-2S model wireless remote control.

- For a fixed MD type two-speed electric hoist, choose the wireless remote control model F21-2D.

Monorail overhead crane

Need to move in four directions

F21-4S/F21-4D Transmitter

When you need to lift the equipment forward and backward/lift and lower four-direction operation, you can choose the wireless remote control model F21-4S/ F21-4D.

- For running a CD single-speed electric hoist, choose the F21-4S model wireless remote control.

- For running the MD two-speed electric hoist, choose the F21-4D wireless remote control.

1 set of hoisting mechanisms on an overhead crane or gantry crane

Need to move in six directions

F21-E1/F21-E2/F21-E1B/F24-6D/F26-C Transmitter

When you need the crane to move forward and backward with only one hoist or trolly lifting and lowering/moving left and right, you can choose the wireless remote control of the F21-E1/F21-E2/F21-E1B model of the F21 series, or the wireless remote control of 6 buttons such as F24-6S/D of F24 series and F26-C of F26 series, etc. F21 series and F24-6S are one-step button controls, which can only match the equipment whose running and lifting are single-speed.

- The F21 series and F24-6S are one-step button controls and can only be matched with equipment that runs and lifts at a single speed. the F21 series is cheaper, for example, the F21-E1B is $46/set, and the F21-E1/ F21-E2 are both $40/set.

- F24-6D and F26-C have more contacts to match more complicated operation situations.

2 sets of hoisting mechanisms on an overhead crane or gantry crane

According to the specific needs of the function to choose 6 keys / 8 keys / 10 keys of the wireless remote control type

- Need to control the movement and lifting of two trolleys separately.

- Need to control the movement of two trolleys separately, but require the same lift and lowering

- Need to control the movement and elevation of two trolleys at the same time.

Scenarios for Use in Harsh Environments (Explosion-proof and Metallurgical Environments)

When the use of the environment there are flammable and explosive gases and dust mixtures of hazardous media, in order to ensure the safe and stable efficient operation of equipment, to avoid and eliminate the occurrence of production accidents, this time should be used with anti-static, spark-proof, fire-retardant characteristics of the better explosion-proof environment of the special remote control.

Designed by using a smaller control current and small capacity battery to prevent the operation of the current is too large to cause a short circuit of the circuit, thereby triggering a spark, resulting in failure or accident. According to the requirements of the national standard, the operating panel and keys are designed with stainless steel materials that are anti-static or do not generate sparks due to friction.

Mainly used in Chemical plants, gas plants, oil refineries, cement plants, flour mills, coal mines, and other places to achieve remote control of lifting machinery.

In a metallurgical environment using an ordinary remote control life of about a year, the use of explosion-proof remote control can be used for 2-3 years, because the explosion-proof remote control of dust-proof, water-proof, anti-oil design can make the remote control can have a longer life.

Operating Conditions That Require Consideration of Immunity to Interference

When there are more cranes in a workshop, choose the crystal oscillator type remote control for better anti-interference ability.

In remote control technology, the main difference between plug-in and crystal remote control is the different frequency regulation mechanism:

Crystal crane wireless remote control

- Crystal remote controls use a crystal oscillator to generate a fixed frequency. This type of remote control usually has higher stability and accuracy.

- They are widely used in applications that require precise control and stabilization of signals, so they are relatively more resistant to interference.

- The frequency of the crystal is usually fixed, which means the frequency between the remote control and the receiver must be strictly matched.

Card-type crane wireless remote control

- The core function of a plug-in remote control is to allow the user to change the operating frequency of the remote control by changing the plug-in card. This allows the same remote control to control different devices by changing the frequency card.

- This type of remote control is ideal for environments where there are multiple devices to be controlled and these devices may operate on different frequencies.

- It provides a flexible solution that can be adapted to different control needs by simply changing the frequency card.

The choice between these two types of remote controls is based on the specific application requirements and environmental conditions, with the crystal type having the advantage of stability and accuracy, while the plug-in card type is more outstanding in terms of flexibility and versatility.

The card-type crane wireless remote control is more cost-effective, easy to pair, and suitable for situations where an emergency replacement is needed.

Require Multiple Devices to Be Raised and Lowered at the Same Time

The dual trolley needs to be the same as the lift and lower the crane wireless remote control program, that is, a transmitter, and two or more receiver designs, so that the operator can operate on a remote control device, to achieve more accuracy with the same lift and lowering, especially suitable for lifting piles of materials. In addition, the remote control of the QE trolley is recommended to use the F24-12S/D model, more buttons can realize a more flexible operation situation, and the price is $100-120.

In Conclusion

- Crane wireless remote control has a button type/rocker type operation form, which needs to be chosen according to the specific use of the scene, such as conventional workshop lifting equipment for lifting small and light workpieces, it is appropriate to choose button type remote control, simple operation, flexible and lightweight. Equipment to achieve more functions, and more control points, suitable for the choice of joystick remote control.

- Key type selection, according to the needs of the lifting operation needs to match the corresponding number of keys.

- In explosion-proof environment and metallurgical environments, it is recommended to choose an explosion-proof industrial remote control, that matches the use of the environment because an explosion-proof industrial remote control with a dust-proof, water-proof, and oil-proof design can make the remote control have a longer life.

- Crystal-type crane wireless remote control has higher stability and accuracy, suitable for the use of the environment needs to consider the anti-interference ability.

- Card-type crane wireless remote control is outstanding in flexibility and versatility, suitable for easy pairing and convenient replacement scenarios.

- Customized industrial remote control is required for the scenarios that require the same ascending and descending.

DGCRANE not only has rich experience in crane customization, but also has accumulated a lot of customer cases in customized crane remote control solutions, we have a strong team of engineers, and also have very strong suppliers to provide us with high-quality crane remote control, if you have the need in this area, contact your dedicated customer service!

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!