- INDUSTRIES

-

EQUIPMENT

-

Overhead Cranes

-

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

- Light Cranes

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US

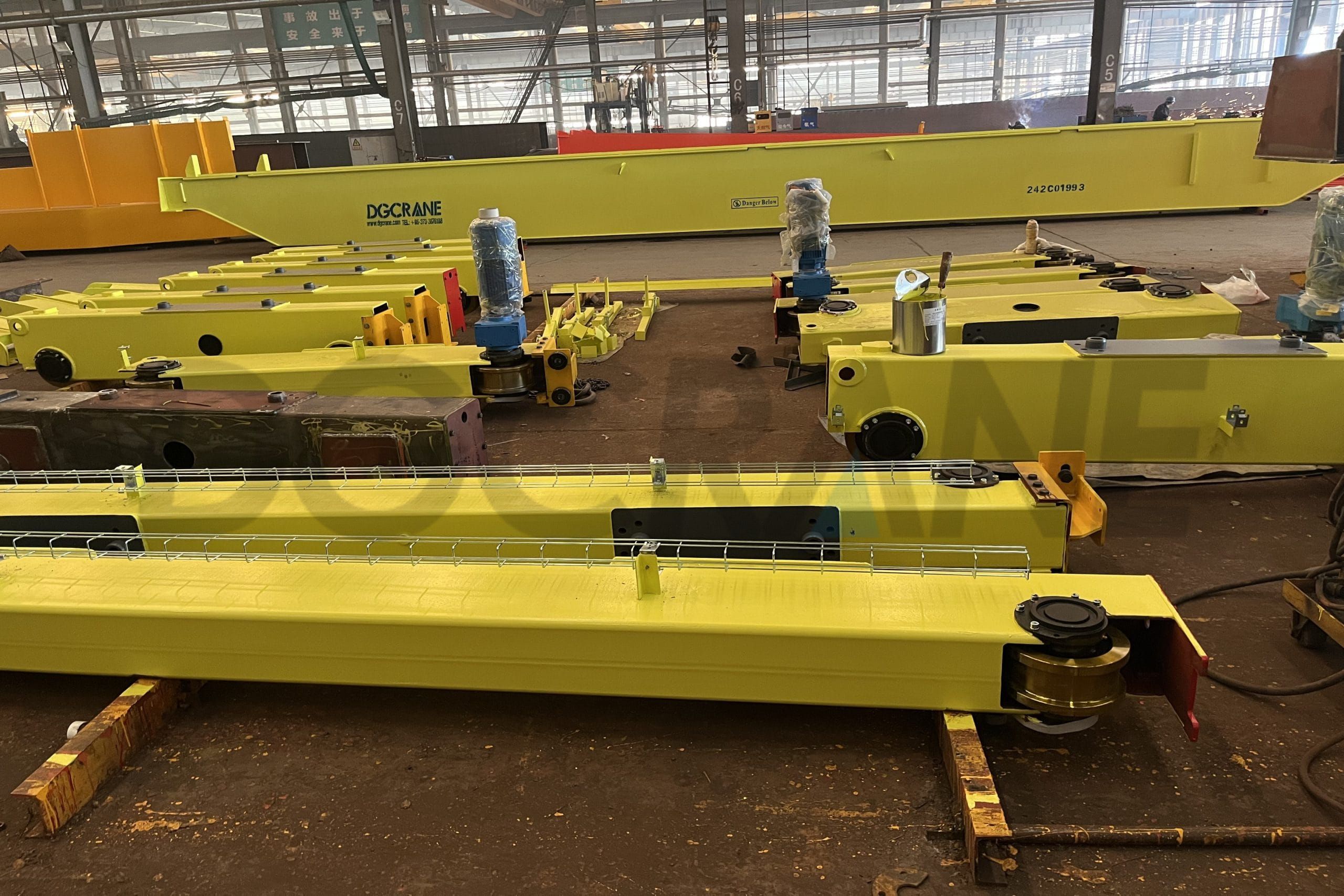

Rapid Delivery of 13 Sets of Overhead Cranes with Supporting Steel Structures to the U.S.

Crane specification:

Double Girder Overhead Crane

Crane model: NLH

Capacity: 6(3+3) ton

Span length: 16m/12m

Lifting height: 7m

Work duty: A5

Power source: 460V/60Hz/3Ph

Control mode: Pendant + remote control

QTY: 3 sets

Double Girder Overhead Crane

Crane model: NLH

Capacity: 25 ton

Span length: 14m/12m/14m

Lifting height: 7m

Work duty: A5

Power source: 460V/60Hz/3Ph

Control mode: Pendant + remote control

QTY: 4 sets

Single Girder Overhead Crane

Crane model: HD

Capacity: 5 ton

Span length: 14m

Lifting height: 7m

Work duty: A5

Power source:460V60Hz/3Ph

Control mode: Pendant + remote control

QTY: 4 sets

Single Girder Overhead Crane

Crane model: HD

Capacity: 20(10+10) ton

Span length: 14m

Lifting height: 7m

Work duty: A5

Power source:460V60Hz/3Ph

Control mode: Pendant + remote control

QTY: 1 set

Single Girder Overhead Crane

Crane model: HD

Capacity:10 ton

Span length: 14m

Lifting height: 7m

Work duty: A5

Power source:460V60Hz/3Ph

Control mode: Pendant + remote control

QTY: 1 set

The delivery of 13 sets of cranes within 4 weeks is both an opportunity and a challenge. Following is the story between professional transformer manufacturer from USA and DGCRANE.

Like most customers, the early communication went smoothly and the client was satisfied with our solution. When we learned that the customer wanted 13 cranes and steel structures to be completed within 4 weeks and loaded into containers in the fifth week, we felt that was a challenge. We had no problem with cranes and steel structures, but the matching electrical components and motors were indeed a challenge for us. After coordination by leaders of various departments of our company, we finally agreed to the delivery requirements.

Another point is that the size of the crane exceeds the length of the container, but the cranes are not allowed to be cut, and the customer’s requirement for transportation time must be controlled within 20 days. This problem is a bit beyond our control. Here we would like to thank our experienced freight forwarder for helping us think of many ways. Finally, we chose to use 53-foot containers to transport them to the Port of Los Angeles and then transport them to Texas by land.

Soon, we signed a contract with the customer and prepared materials and purchased parts in a hurry. The whole production process was tense but orderly. All bridge cranes were produced in an orderly manner within the agreed time. At the same time, containers also arrived at the factory one after another.

When the containers arrived at the Port of Los Angeles, we also encountered problems. Texas is far from California. Due to the clear requirements of American roads, our containers were asked to be adjusted, but the problem was quickly solved. When the unclear containers arrived at the customer’s factory one after another, our engineers who were installing in Mexico had just finished their work on site and arrived at the customer’s factory as scheduled.

The installation of 13 bridge cranes was completed in two and a half months. During the installation, our business manager also arrived at the customer’s installation site and discussed new projects with the customer. We look forward to the next cooperation and long-term cooperation.

From design to delivery, we ensure every crane solution meets the highest standards of performance and reliability. Choose us for dependable equipment—and a partner you can trust every step of the way.

Zora Zhao

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

With 10+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

WhatsApp: +86 158 3611 5029

Email: zorazhao@dgcrane.com

Related Cases

Subscribe to our newsletter

The latest DGCRANE price list, news, articles, and resources.

- Overhead Cranes

- Low Headroom Overhead Cranes

- Double Girder Overhead Crane

- Grab Bucket Overhead Crane

- Top Running Overhead Crane: Wide Application and Easy Maintenance

- Coker Cranes for Harsh Environments: High Temperature and Corrosion Resistant Design

- Single Girder Overhead Cranes

- Eot Cranes

- Eot Crane

- Single Girder Eot Cranes

- Double Girder Eot Cranes

- Underslung Cranes

- Gantry Cranes

- Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

- Truss Gantry Cranes: Cost-Effective, Wind-Resistant, and Perfect for Large Spans

- Gantry Crane

- Different Types of Small Portable Aluminium Gantry Cranes: Cost Effective

- Single Girder Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Casting Yard Gantry Cranes

- Container Gantry Cranes (RMG)

- Portable Gantry Cranes

- FEM Standard Crane & Hoist

- FEM Standard Overhead Cranes

- FEM Standard Gantry Cranes

- FEM Standard Jib Cranes

- FEM Standard Wire Rope Electric Hoists

- FEM Standard Electric Chain Hoists

- Hoist & Winch Trolley

- Low Headroom Wire Rope Electric Hoist: Compact Design for Efficient Lifting in Tight Spaces

- Electric Hoist for Molten Metal: High-Temperature, Safe Lifting for Metallurgical Environments

- Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

- 6 Double Girder Trolley Electric Hoists for Overhead Cranes: Custom Solutions for Every Lifting Need

- Manual Chain Hoists: Alloy Steel Construction for Smooth and Safe Lifting

- Electric Wire Rope Hoists

- Chain Hoists

- Crane Trolley

- Electric Winch

- Port Cranes

- Rubber Tyred Container Gantry Crane

- Ship To Shore Crane

- Container Straddle Carrier

- Harbour Portal Crane

- Shipyard Portal Cranes

- Reliable Versatile Electric Transfer Carts

- Powerful Heavy Duty Coil Transfer Carts

- Powerful Pallet Transfer Carts

- Rail Transfer Carts

- Reliable Heavy Duty Ladle Transfer Cars

- RGV Transfer Carts

- Superior Die Transfer Carts

- Trackless Transfer Carts

CRANE PARTS

- Special Cranes

- Rail Mounted Container Gantry Crane

- Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

- Charging Cranes for Steel Production: Safe and Reliable Solutions for Efficient Material Handling

- Insulated Overhead Cranes for Safe Non-Ferrous Metal Smelting

- Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

- Quenching Overhead Crane for Heat Treatment Plant: High-Temperature Insulated and Efficient Lifting Solution

- Heavy Duty Forging Cranes: Durable, High-Capacity Solutions for Forging

- Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

- 35-65t Clamp Overhead Crane

- Boat Hoists

- Yacht Davit Crane

- Boat Jib Crane

INDUSTRIES

COMPANY

- sales@dgcrane.com

- +86-373-3876188

- +86 158 3611 5029

- Floor 30,Gongyuan INT'I Building, Jinsui Road, Xinxiang City, Henan Province, China