Overhead Crane Installation and After Sales Service

Receiving goods

When the customer receives the lifting equipment, the following needs to be checked:

- Inspection-Check whether the list is compared with the physical object (whether the quantity of the goods is complete, whether the parts are damaged, and whether the random information is complete.)

What preparation plans will DGCRANE make for you before installation?

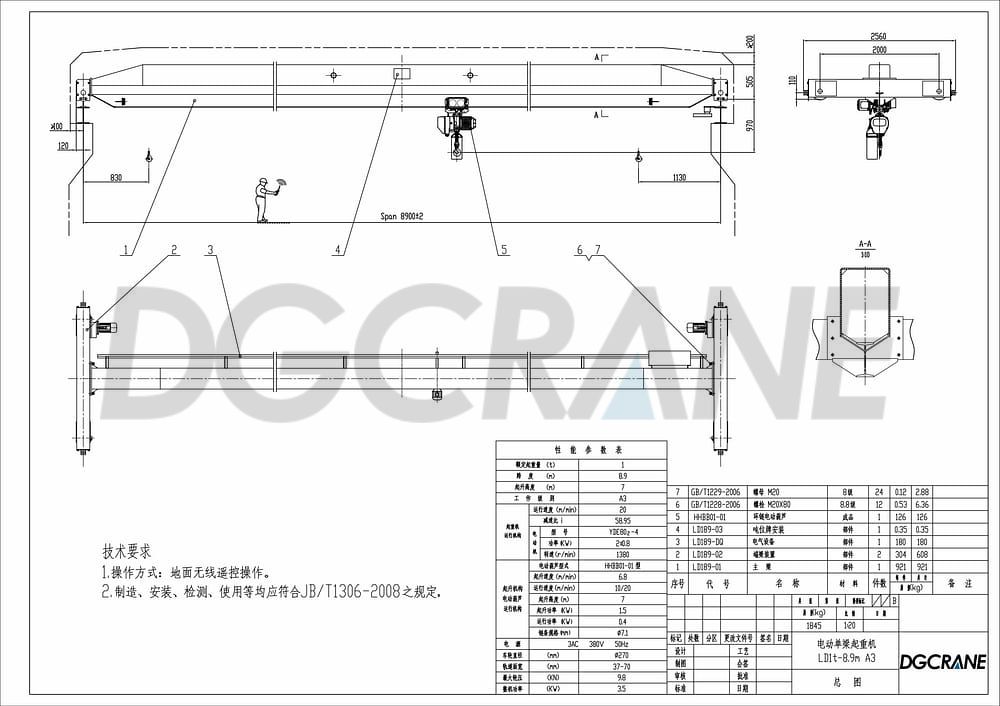

1. Pre-installation planning: Blueprint

Before installation, our engineers and installation masters should communicate with you the following details to facilitate the smooth progress of the installation, including:

- Review of plant building drawings:Carefully check the building design blueprint to ensure that the key structural dimensions of the plant meet the requirements of the crane installation dimensions

- List of materials and equipment:During the whole process of crane installation, the installer listed a complete list of necessities.

- Installation schedule:Installers need a clear timetable to avoid delays in ongoing construction.

- Installation notice:Confirm the installation schedule, personnel cooperation (mechanical and electrical engineers, technical guidance during the installation process), planning progress, construction safety, and cleaning up the site; at the same time, it is necessary to investigate the on-site environment (preparation of installation tools, determine the power supply voltage of the buyer’s installation site, to ensure that the customer has the basic conditions required for installation.)

On-site review:Local situation

The installers will make relevant preparations before installing the crane to ensure that the installation vehicles and machinery and equipment can pass freely and ensure the smooth progress of the installation.Key considerations include:

- Check the matching degree of the customer’s local power lines, power supplies and products.

- The status of the pavement on the installation site.

- Roof and plumbing system.

- Overhead lamps.

- Preparation of welding equipment.

- We will ensure with every customer the basic conditions for installing the crane.

Before the crane is installed, the installation conditions that must be met: the cleaning of the installation site, the preparation of safety facilities, the provision of power supply conditions, the preparation of installation equipment, the preparation for the installation of the trolley track and the trolley power supply slip line, etc.

Hazard identification: Safety first

- This step involves identifying potential hazards that may interrupt the installation process, such as:

- Electrical hazard

- Mechanical hazard

- Extreme temperature or chemical exposure

- Precautions for aerial work

- Any other risks that the installer deems relevant

Load test

After the installation of the bridge crane is completed, it is time for the load test.The test steps are as follows:

- Operation experiment of hoist, crane beam, crane trolley

- Safety device function check

- Load test of 125% of the rated lifting weight of the crane

- Always keep load test records easy to access for future reference.

- Load test, dynamic load test (1h) and static load test (3*10 min), mainly check whether the functions of each mechanism and transmission can be operated.

How to install? Assembly steps of overhead crane

The first step in installation is to ensure that on-site safety protection measures are in place, check whether the installation of the crane beam is in good condition, and then implement the installation.

STEP1:Pre-installed

STEP2:Assembly and installation

STEP3:Testing and final adjustment

After-sales service we can provide you with:

In the crane manufacturing process, we will fully cooperate with the arrangement of drawings, product supervision, inspection and acceptance to ensure that you receive a high-quality bridge crane, as follows:

1. About qualification certificate

DGCRANE has ISO certification, CCC certification, CE certification, etc., WE can provide you with the third-party certification of the bridge crane you need.At present, international export certification mainly includes seven categories, namely ISO9000, CCC mark, TüV certification, UL certification, CE certification, RoHS certification, SGS commodity inspection.

| ISO(International Standards Certification Organization) | A global alliance of international standardization agencies (ISO member agencies). |  |

| CCC(China compulsory certification) | China’s compulsory certification is referred to as CCC, and the 3C mark is referred to as.Transportation, import, sale and use in commercial services. |  |

| TÜV certification | TÜ Vcertification It is a third-party certification issued by TüV NORD, the official certification body of the German government. |  |

| UL certification(Underwriter Laboratories Inc) | It uses scientific testing methods to determine the degree of harm or harm to life and property caused by various materials, installations, products, facilities, buildings, etc.; Determine, prepare and issue appropriate standards and help reduce and prevent lives. |  |

| CE certification | It is a safety certification mark and is regarded as a passport for manufacturers to open and enter the European market. |  |

| SGS(Swiss General Notary Office) | It is the world’s leading inspection, identification, testing and certification body, providing a wide range of physical, chemical and metallographic analysis, including destructive and non-destructive testing, providing a complete set of quantitative and quality inspection and related technical services, and providing customers with pre-testing services. |  |

| RoHS certification | It mainly regulates the material and process standards of the electrical equipment of bridge cranes to make them more conducive to human health and environmental protection. |  |

2.Regarding transportation and charges

DGCRANE will provide packaging in accordance with international export standards: the main beam needs to be cut during transportation, and it will be bolted together after being shipped to the local area, which is strong and reliable. The host is packed in rainproof colored strips, and the spare parts and electrical equipment are packed in fumigated wooden boxes. DGCRANE can provide a variety of crane transportation, such as container/bulk cargo transportation/LCL shipping, train transportation.

3.About our experience-case

Installation and trial operation of 16t overhead crane in Tanzania

This is an LDC single-beam bridge crane with a lifting weight of 16 tons exported to Tanzania. According to the customer’s requirements, we arranged for an engineer to go to the customer’s site to guide the installation of the crane. We arrived at the customer’s site on July 16th and returned to our factory on August 29th. Here are some product and installation pictures.

After-sales service

After DGCRANE’s products are sold, there is a 1 to 2-year warranty.Our experienced technical personnel will go to the site free of charge to guide the crane installation according to the date required by the customer, help the customer adjust the crane on site, guide the load test and commissioning, and train the customer.

Each crane is accompanied by a manual, and we can also arrange remote technical guidance.

It is worth noting that:

- Maintenance: Regular maintenance is necessary, including daily, monthly, and annual inspectionsThe first thing is to ensure the safe and efficient operation of the crane.We can provide repair services and spare parts as needed.

- Maintenance: If a failure or malfunction occurs, we can provide timely and efficient maintenance services to minimize downtime.

- Training: We can provide training for operators and maintenance personnel to ensure the safe and efficient operation of the crane.

Crane is the world’s leading crane manufacturer. It is not only responsible for the free consultation of cranes, but also provides corresponding technical guidance and technical cooperation such as engineering planning, civil engineering, equipment supervision and inspection related to lifting equipment.

DGCRANE crane services include crane consulting, crane solution design, crane manufacturing quality control, crane installation, crane maintenance, etc., 7*24 hours online service to solve your crane problems.If you have any needs, please contact us.

FAQs

1.What qualifications do bridge crane installers need to pass?

Technical person in charge

Have the title of engineer, graduated from mechanical or electrical related majors, and have technical work experience related to licensed projects.

Quality assurance system personnel

(1) Quality assurance engineer, with the title of engineer and technical work experience related to the licensed project

(2) Personnel responsible for installation plan design, hoisting, welding, commissioning, inspection and quality control system

Technical staff

There are not less than 8 mechanical and electrical professionals with the title of assistant engineer or above, including not less than 6 with the title of engineer, with technical work experience related to the licensed project.

Inspector

There are not less than 4 quality inspectors.

Operator

There are not less than 4 installers, no less than 2 drivers, no less than 2 welders, and no less than 2 electricians.

Project leader

Have the title of engineer, graduated from mechanical or electrical related majors, and have work experience in lifting machinery installation.