Care and Maintenance of Wire Ropes: In The Whole 6 Stages

Crane wire ropes are regarded as an expendable component and we need to take proper care of them to ensure their longevity and durability. Their safe and long-term use depends on the maintenance they receive.

The content of this article includes 6 main parts: Loading and offloading, storage, pre-installation, installation, commissioning, maintenance, and replacement of wire ropes.

1. Maintenance of wire rope in offloading and storing

- To avoid accidents and/or damage to the rope, it should be offloaded with care.

- Reels or coils of rope shall not be dropped, neither shall they be struck by a metal hook or fork of a lift truck or any other external force that could damage or deform the rope.

- Ropes should be stored in a cool, dry building and should not be allowed to be in contact with the floor. They should not be stored where they are likely to be affected by chemicals, chemical fumes, steam, or other corrosive agents.

- If outdoor storage cannot be avoided, ropes should be covered so that moisture cannot induce corrosion.

- Ropes in storage shall be checked periodically for any signs of deterioration such as surface corrosion and, if deemed necessary by a competent person, dressed with a suitable preservative or lubricant that is compatible with the rope manufacturing lubricant.

- In warm environments, the reel should be periodically rotated one half-turn to prevent drainage of lubricant from the rope.

2. Maintenance of the wire rope prior to installation

- Before installing the rope, and preferably on receipt, the rope and its certificate should be checked to ensure that the rope is in accordance with that ordered.

- The minimum breaking force of the rope to be installed shall not be lower than that specified by the crane manufacturer.

- The diameter of the new rope shall be measured in a straight section with the rope under no tension and the value (dm) recorded.

- Where a wire rope has been kept in storage for a period of time during which corrosion might have occurred, it may be advantageous to perform visual inspection and an MRT.

- Check the condition of all sheave and drum grooves to ensure that they are capable of accepting the size of the new rope, do not contain any irregularities, such as corrugations, and have sufficient remaining thickness to safely support the rope.

- The sheave groove diameter should be between 5 % and 10 % larger than the nominal rope diameter. For optimal performance the groove diameter should be at least 1 % greater than the actual diameter of the new rope.

3. Wire rope installation

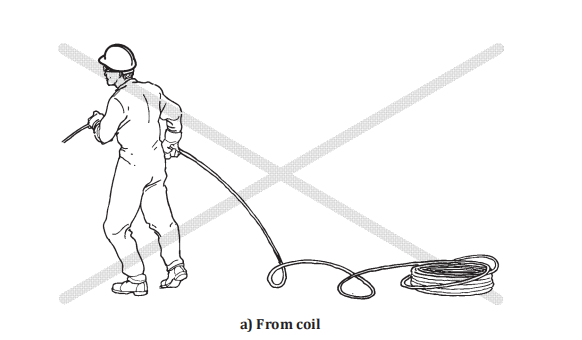

- When uncoiling and/or installing wire rope on crane, every precaution in wire rope installation procedure shall be taken to avoid inducing turn into, or out of, the rope. Allowing this to occur can result in the formation of loops, kinks or bends in the rope, rendering it unfit for use.

- In order to prevent any of these developing, the rope should be paid out in a straight line with a minimum of slack being allowed to occur.

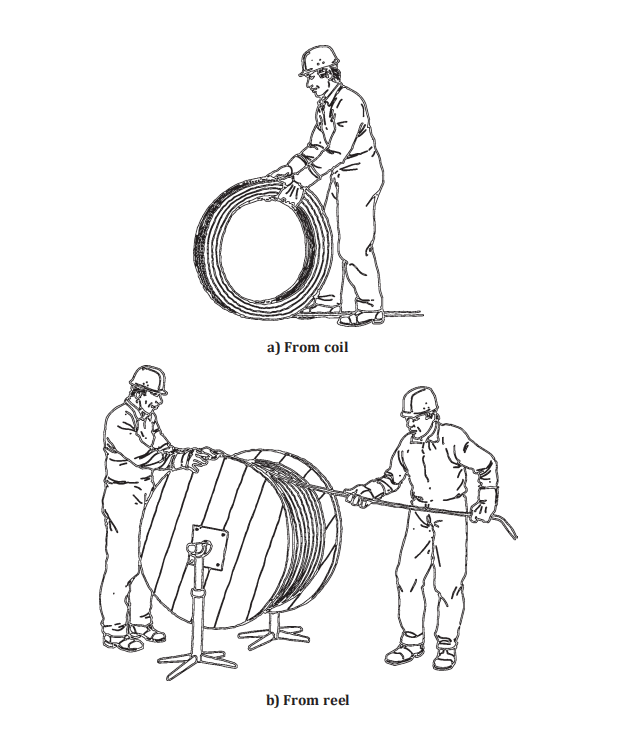

- Rope supplied in a coil should be placed on a turntable and paid out straight; however, where the coiled length is short, the outer rope end may be made free and the remainder of the rope rolled along the ground.

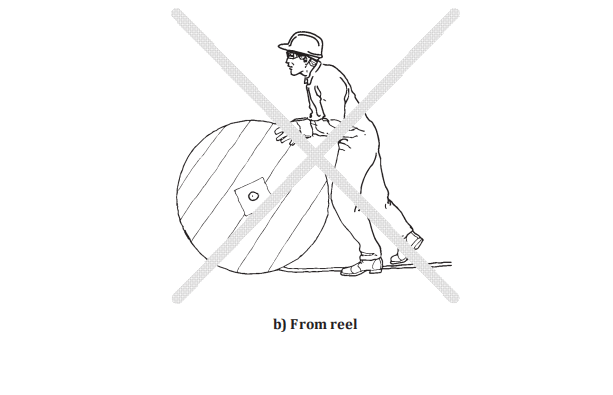

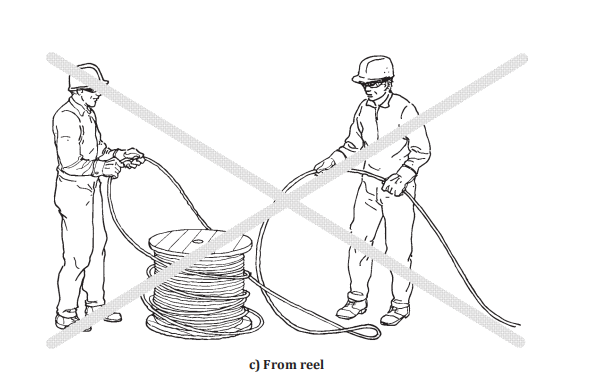

- A rope shall never be paid out by throwing off wraps when the coil or reel is flat on the ground or by rolling the reel along the ground.

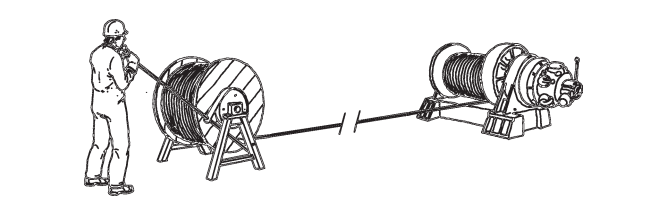

- For those lengths of rope supplied on a reel, place the supply reel and its supporting stand or cradle as far away from the crane or hoist as possible, in order to limit any fleet angle effects to an absolute minimum and thus avoid any undesirable rotational effects.

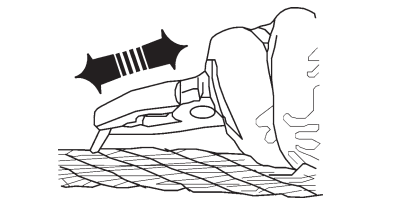

- Protect the rope from any potential ingress of grit or other contaminants by running it on suitable matting (e.g. used conveyor belting), rather than allowing it to run directly on the ground.

- Be aware that a revolving reel of rope can have a high inertia, in which case it needs to be controlled in order to slowly pay out the rope. For smaller reels, this is usually achieved by employing a single brake. Larger reels have significant inertia once they start to revolve and might need to be substantially braked.

- As far as is practicable, ensure that the rope always bends in the same direction during installation, i.e. pay out the rope from the top of the supply reel to the top of the drum on the crane or hoist (referred to as “top-to-top”), or from the underneath of the supply reel to the underneath of the drum on the crane or hoist (referred to as “bottom-to-bottom”). For an example of “bottom-to-bottom”.

- For those ropes that are subjected to multi-layer spooling, apply a back-tension to the rope during installation equivalent to about 2,5 % to 5 % of the minimum breaking force of the rope. This helps ensure that the rope on the bottom layer is tightly wound, forming a firm base for succeeding layers.

- Follow the crane manufacturer’s instructions for the securing of the ends of the rope at the drum and outboard anchorages.

- Protect the rope from rubbing against any part of the crane or hoist during installation.

4.Running-in the new wire rope

- Before bringing the rope into full operation on the crane, ensure that all hoisting limiting and indicating devices associated with the operation of the crane are correctly functioning.

- In order to allow the components of the rope to better adjust to the normal operating conditions, the crane should be operated at reduced speed and loading [i.e. down to 10 % of the working load limit (WLL)] for a number of operational cycles.

5. Wire rope maintenance

- Care and maintenance of wire ropes shall be carried out relative to the type of crane, its frequency of use, the environmental conditions and the type of rope.

- During the life of the rope, and before it shows any signs of dryness or corrosion — particularly over those lengths which travel through sheaves and enter and exit the drum and those sections which are coincident with a compensating sheave — the rope shall be dressed from time to time, as determined by a competent person. In some cases, it may be necessary to clean the rope before applying the dressing in order for it to be effective.

- The rope dressing shall be compatible with the original lubricant applied by the rope manufacturer and shall have penetrating characteristics. If the type of rope dressing is not identified in the crane manual, the user shall seek guidance from the supplier of the rope or the wire rope manufacturer.

- A shorter rope life is likely to result from a lack of maintenance, particularly if the crane or hoist is used in a corrosive environment or, for whatever reason, no rope dressing can be applied. In such cases, the period between inspections shall be reduced accordingly.

- In order to avoid any localized deterioration, which might otherwise originate from a broken wire protruding excessively from the rope and overlying others when that portion travels through a sheave, it may be removed by gripping the protruding end(s) and bending the wire backwards and forwards, until it eventually breaks (invariably in the valley position between the strands). When a broken wire is removed from the rope as part of a maintenance exercise, its location should be recorded for the information of the rope inspector. If such action is taken, this shall be counted as a broken wire and taken into account when assessing the condition of the rope in relation to the discard criteria for broken wires.

- When broken wires are evident close to or at the termination, but the rope is unaffected elsewhere along its length, the rope may be shortened and the terminal fitting refitted. Before this is done, the remaining length of wire rope shall be checked to ensure that the required minimum number of wraps would remain on the drum with the crane at its most extreme operating limit.

6.Wire rope replacement

- Unless an alternative rope has been approved by the crane manufacturer, rope manufacturer or other competent person, only a rope of the correct length, diameter, construction, type and direction of lay and strength (i.e. minimum breaking force), as specified by the crane manufacturer, shall be installed on the crane. A record of the rope change shall be placed on file.

- In the case of larger-diameter, rotation-resistant ropes, it may be necessary to apply additional means of securing the rope ends, e.g. through the use of steel straps or servings, particularly when preparing samples for testing.

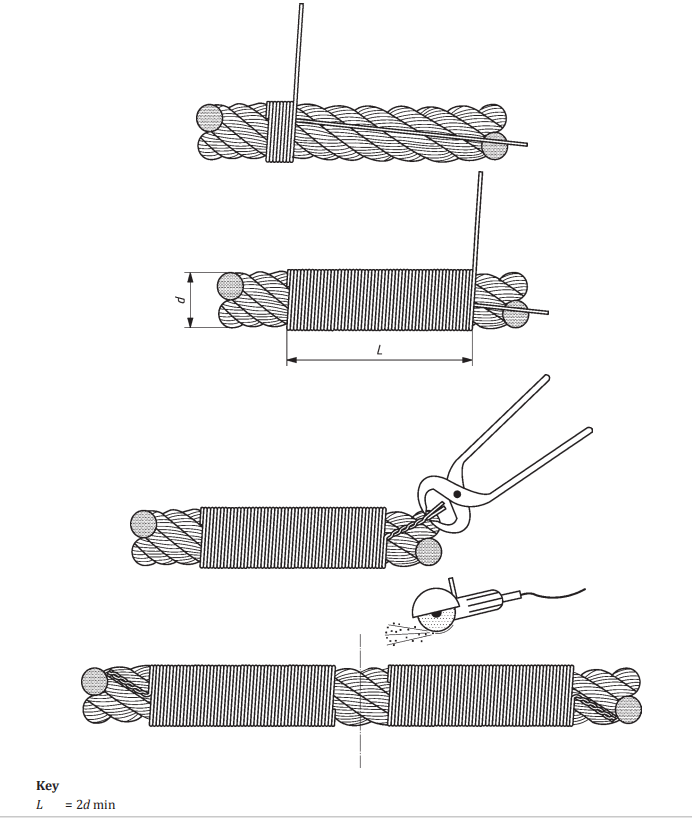

- If the length of rope required for use is to be cut from a longer length, such as a bulk-manufactured reel of rope, servings shall be applied at both sides of the intended cutting point to prevent the rope from unlaying (i.e. unravelling) after the cut has been made.

- The follow figure shows an example of how a single-layer rope should be served before cutting.

For rotationresistant and parallel-closed ropes, multiple-length servings may be necessary. An alternative method for larger-diameter, rotation-resistant ropes is shown in the follow figure. Ropes that are only lightly preformed are more likely to unlay/unravel after cutting, if inadequate or insufficient servings are applied.

NOTE :Serving is sometimes referred to as “seizing”

- Unless an alternative rope termination has been approved by the crane manufacturer, rope manufacturer or other competent person, only one of a type, as specified by the crane manufacturer in the operator's manual, shall be used to attach a rope to a drum, hook block or anchor point on the machinery structure.

- It is beneficial to take a base trace for the MRT by testing the rope before installation or as soon as practical after installation.

The content of the article is taken from ISO4309-2017. It was last reviewed and confirmed in 2023. Therefore this version remains current. China will adopt the standard in December 2023.

DGCRANE is specialized in exporting cranes overseas, we have excellent crane experts and engineers to escort our customers in the design of their products, the selection of materials and the subsequent use, maintenance and repair. If you have any questions or needs about cranes and their accessories, please feel free to contact me.

Email: zora@dgcrane.com

WhatsApp: +86 158 3611 5029

For more information please download ISO4309-2017

Reference:Crane Maintenance: Wire Rope Inspection