Installation of Gantry Cranes (with a Real Case)

Introduction:

Gantry cranes, also known as portal cranes, are essential lifting equipment commonly used in industrial settings. Their installation process typically consists of four main steps. Taking DGCRANE‘s real case in Saudi Arabia as an example, this article will give you a description of each step with infographics. The procedure can be a reference for single girder gantry cranes, double girder gantry cranes, and other types of gantry cranes. The main steps include pre-installation, track installation, assembly of the crane components, and the crucial load test.

The Procedure of Gantry Crane Installation:

Step 1: Pre-installation

Before installing a gantry crane, several crucial preparatory steps need to be undertaken including:

- Site Assessment: A thorough examination of the installation site is necessary to ensure its suitability for a gantry crane. Factors such as ground stability, available space, and potential obstructions must be considered.

- Crane Selection: Based on the site assessment, an appropriate gantry crane should be selected, taking into account factors such as load capacity, span length, and lifting height.

- Position Calculation: Precise calculations are essential to determine the optimal positioning of the crane within the installation site. Factors like load requirements, access points, and operational safety must be considered during this phase.

Step 2: Installation of Tracks

The installation of tracks forms the foundation for the crane’s movement. The process involves the following steps:

- Fix the base plate in the exact position of the runway according to the span of the gantry crane.

- Lay the track on the top of the base plate and adjust it.

- Fix the track on the base plate with clips.

Step 3: Crane Assembly

The assembly of a gantry crane involves these key tasks:

1. Main Beam Assembly:

This procedure is for the case that the main beam is cut off for transportation. Precision in alignment and secure fastening of the components are necessary to ensure structural integrity. During the assembly, raising up both ends of the main beam about 1 meter high by steel frame will make it more convenient.

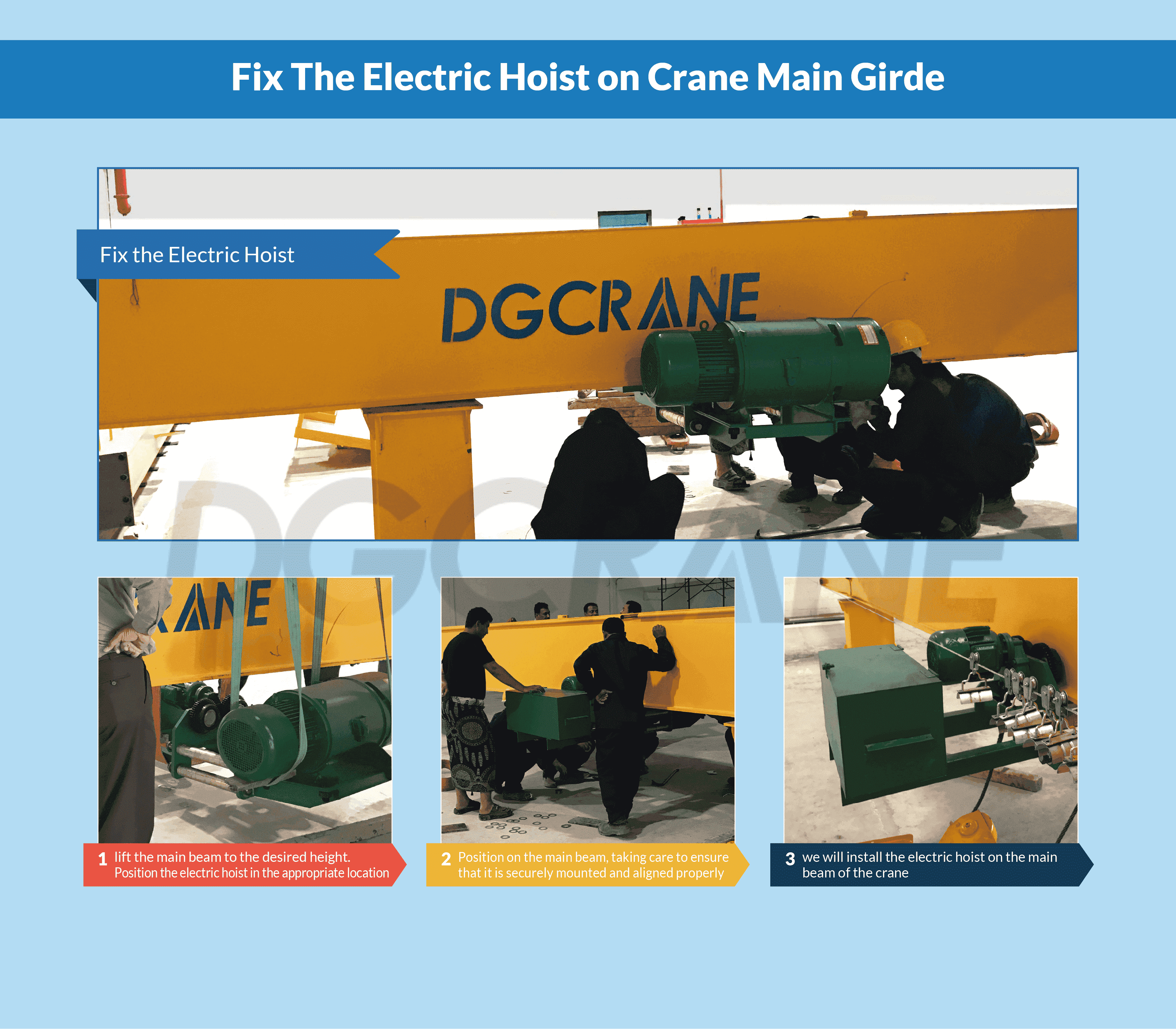

2. Hoist Installation:

The electric hoist, responsible for lifting and lowering loads, is installed onto the main beam. The hoist must be properly aligned, securely fastened, and tested for smooth operation.

3. Cable and Wire Installation:

- Install the cable slide wire and cable trolleys. Fix the cable of the hoist on the trolley.

- Then let the wire of the long traveling motor thread into the pipe on the main beam and the outriggers.

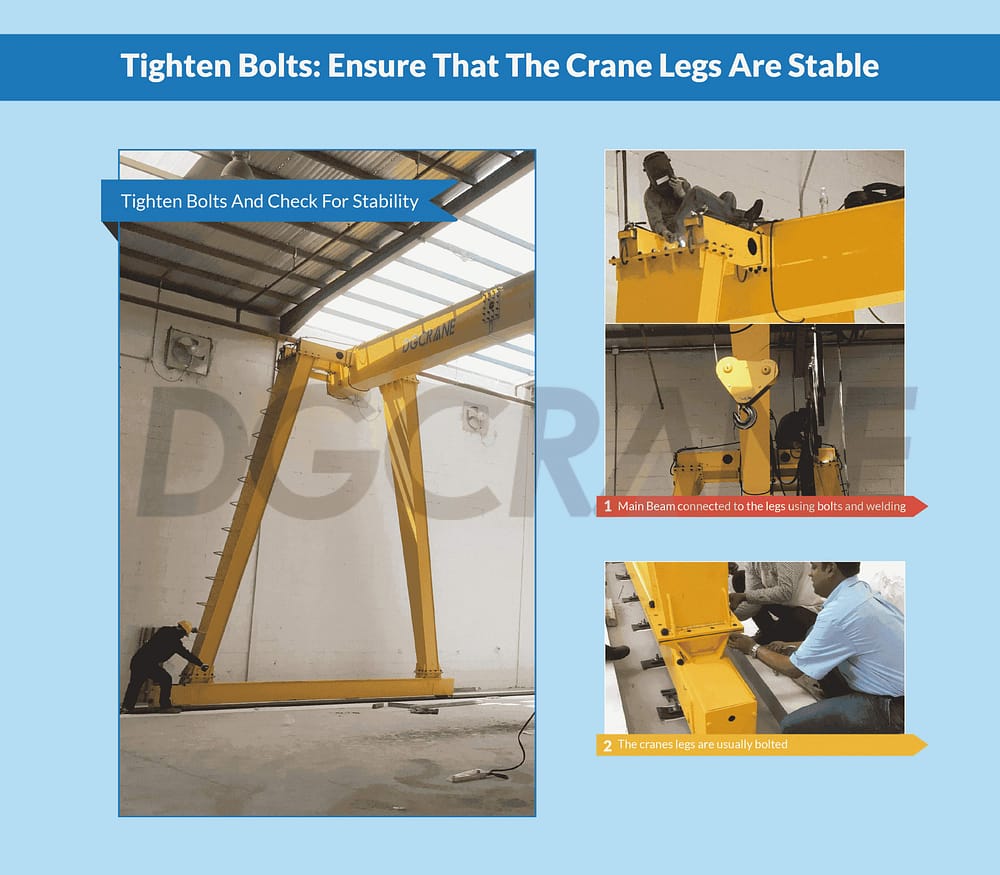

4. Outriggers and Main Beam Installation:

- Place the lower beam on the track.

- Connect the main beam and the outrigger with the wind rope first.

- Then lift the whole system. And adjust the relative position of the outrigger so that the alignment and verticality of the outrigger and the lower beam meet the design.

- Join the outrigger and the lower beam tightly.

- Continue to fix the main beam and the outrigger together.

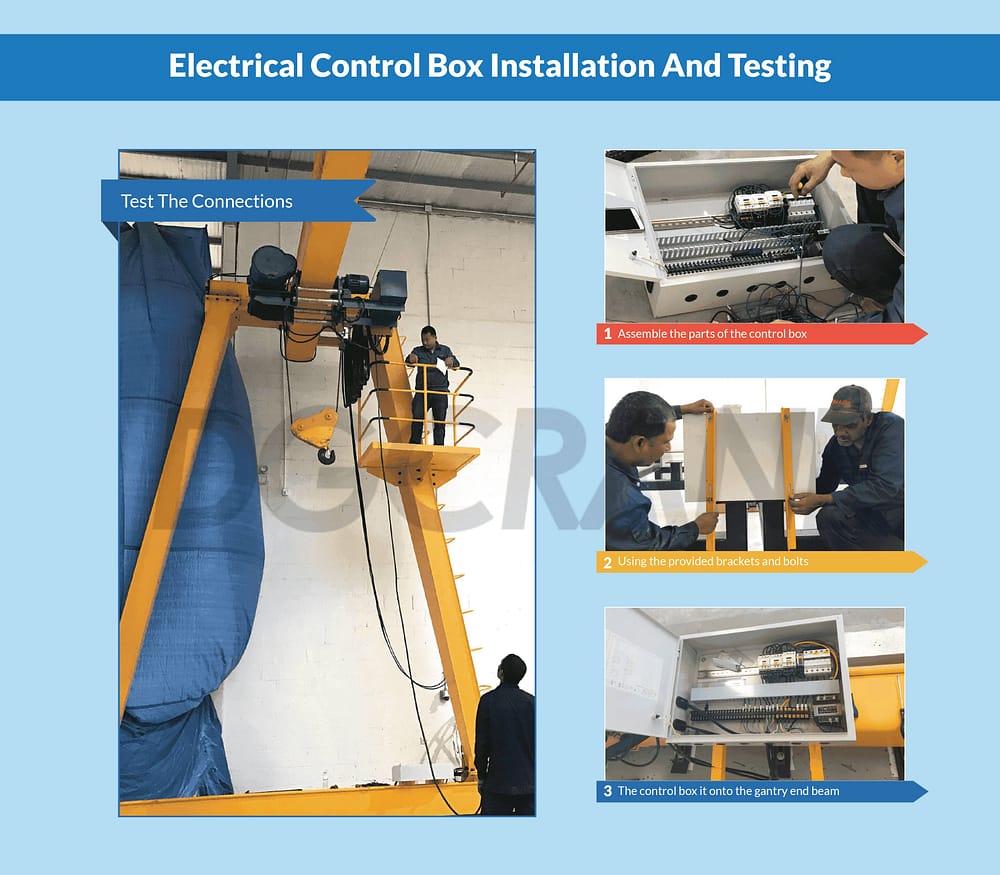

5. Electrical Connections:

All necessary electrical connections, including power supply, control panels, limit switches, and emergency stop systems, are established and tested to ensure proper functionality. Then test the connection.

Step 4: Load Test

Once the gantry crane is fully assembled, a comprehensive load testing procedure is conducted to ensure its safe and reliable operation. The load testing process involves:

- Test Planning: Establishing the load weight, lifting height, and duration of the load test. This plan should adhere to relevant safety regulations and standards.

- Load Application: Gradually apply the test load to the crane while monitoring its response and behavior. This includes observing the crane’s stability, movements, and potential deformations.

- Performance Evaluation: Assessing the crane’s performance during the load test, including its ability to handle the specified load and any signs of structural stress or malfunction.

- Safety Verification: Verifying the operation of safety devices, emergency systems, and control mechanisms to ensure they function correctly during the load test.

- Documentation: Recording the load test results, including load weights, durations, and any observations made during the process. This documentation serves as a reference for future maintenance and safety inspections.

Installation of 5t single girder gantry crane in Saudi Arabia(DGCRANE)

Installation of 5t single girder gantry crane in Saudi Arabia(DGCRANE)

Installation of 10t double girder gantry crane in Saudi Arabia(DGCRANE)

Installation of 10t double girder gantry crane in Saudi Arabia(DGCRANE)

Conclusion:

The installation of a gantry crane involves careful planning, precise execution, and adherence to safety standards. The specific procedures may be different depending on the crane’s design, capacity, and practical situation. It is crucial to engage qualified professionals and strictly adhere to manufacturer guidelines and safety regulations to ensure a successful and safe installation process.

DGCRANE is a crane manufacturer from China with over 10 years of export experience. We provide the tailor-made solution and a complete service for you. To get more information on cranes, installation, and other support services, check out our HOMEPAGE and CONTACT US now!