Inspection And Discard Criteria of Wire Ropes

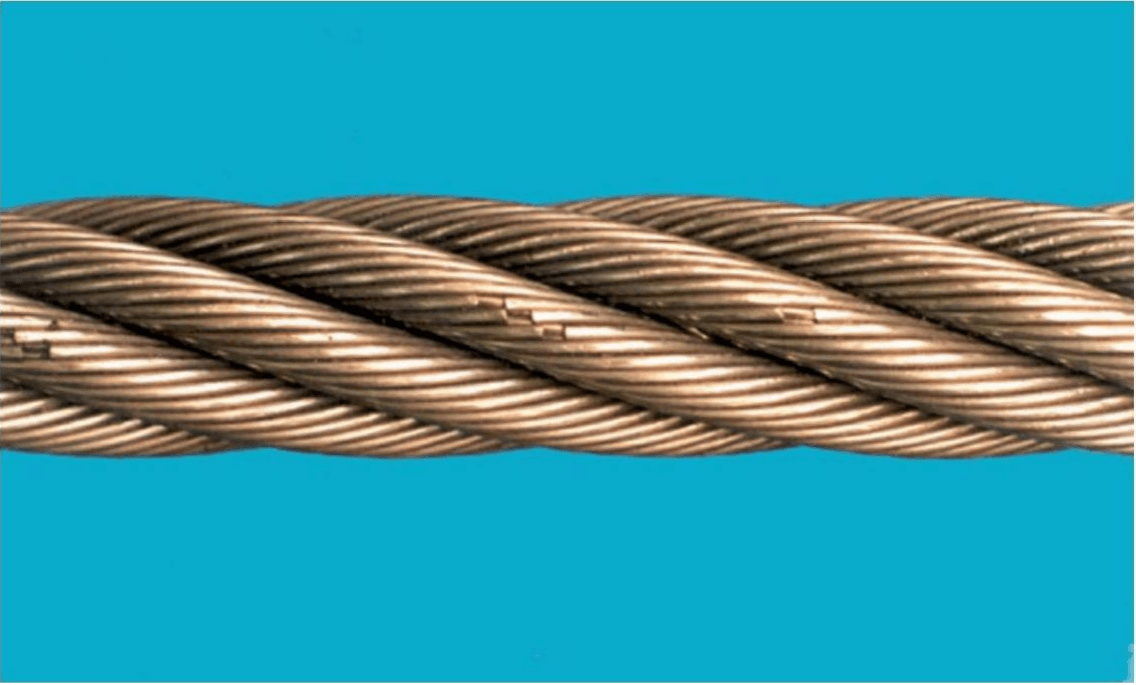

Crane wire ropes are subjected to considerable loads during operation and therefore suffer considerable mechanical damage throughout their service life. In addition, studies have shown that the main causes of wire rope failure are excessive deterioration and corrosion, lack of maintenance and inspection, and misuse leading to premature obsolescence, reduced safety, and increased replacement costs.

Therefore, wire ropes should be inspected and maintained by appropriate personnel to ensure that they are in a safe condition for use. Proper inspection can ensure high performance, long service life, safety of personnel and equipment and reduce operating costs.

1. Daily inspections(visual)

- At least the intended working section of rope for that particular day shall be observed with the objective of detecting any general deterioration or mechanical damage. This shall include the points of attachment of the rope to the crane.

- The rope shall also be checked to ensure that it is sitting correctly on the drum and over the sheave(s) and has not been displaced from its normal operating position.

- Any appreciable change in condition shall be reported and the rope examined by a competent person in accordance with periodic inspections.

- If, at any time, the rigging arrangement is modified, such as when the crane has been moved to a new site and re-rigged, the rope shall be subjected to a visual inspection as described in this subclause.

- The driver/operator of the crane may be appointed to carry out daily inspections to the extent that the driver/operator is sufficiently trained and considered competent to carry out this action.

2.Periodic inspections

2.1 General

- Periodic inspections shall be carried out by a competent person.

- The information gained from a periodic inspection is to be used to assist in deciding whether a crane rope can safely remain in service and by which latest time it shall undergo its next periodic inspection, or needs to be withdrawn immediately or within a specified timeframe.

- Through an appropriate assessment method, i.e. by visual means and/or measurement, or with an MRT, the severity of deterioration shall be assessed and expressed either as a percentage (e.g. 20 %, 40 %, 60 %, 80 % or 100 %) of the particular individual discard criteria or in words (e.g. “Slight”, “Medium”, “High”, “Very high” or “Discard”).

- Any damage that might have occurred to the rope prior to it being run in and entering service shall be assessed by a competent person and observations shall be recorded.

- A list of inspection wire rope damage types and whether each can be readily quantified or needs to be subjectively assessed by the competent person is given in the follow table.

| Mode of deterioration | Assessment method |

| Number of visible broken wires (including those which are randomly distributed, localized groupings, valley wire breaks and those that are at, or in the vicinity of, the termination) | By counting |

| Loss of metallic area caused by broken wires | Visual, MRT |

| Decrease in rope diameter (resulting from external wear/abrasion, internal wear and core deterioration) | By measurement |

| Loss of metallic area caused by mechanism other than broken wires e.g. corrosion, wear, etc. | Visual, MRT |

| Fracture of strand(s) | Visual |

| Corrosion (external, internal and fretting) | Visual, MRT |

| Deformation | Visual and by measurement (wave only) |

| Mechanical damage | Visual |

| Heat damage (including electric arcing) | Visual |

2.2 Frequency of periodic inspections

- The frequency of the periodic inspections shall be determined by the competent person, who shall take account of at least the following:

a) the statutory requirements covering the application in the country of use;

b) the type of crane and the environmental conditions in which it operates;

c) the classification group of the mechanism;

d) the results of previous inspection(s);

e) experience gained from inspecting ropes on comparable cranes;

f) the length of time the rope has been in service;

g) the frequency of use;

h) the crane manufacturer's recommendations.

NOTE 1: The competent person can find it prudent to initiate or recommend more frequent periodic inspections than those required by legislation. This decision can be influenced by the type and frequency of operation. Also, depending on the condition of the rope at any time and/or whether there is any change in circumstances, such as an incident or change in operating conditions, the competent person can deem it necessary to reduce or recommend the reduction of the interval between periodic inspections.

NOTE 2 :Generally, ropes develop broken wires at a greater rate later in the life of the rope than in its early stages.

2.3 Extent of wire rope periodic inspections

Each rope shall be inspected along its entire length.

However, in the case of a long length, and at the discretion of the competent person, only the working length plus at least five wraps on the drum may be inspected. In such a case, and where a greater working length is subsequently foreseen after the previous inspection and prior to the next one, that additional length should also be inspected before the additional length of rope is used.

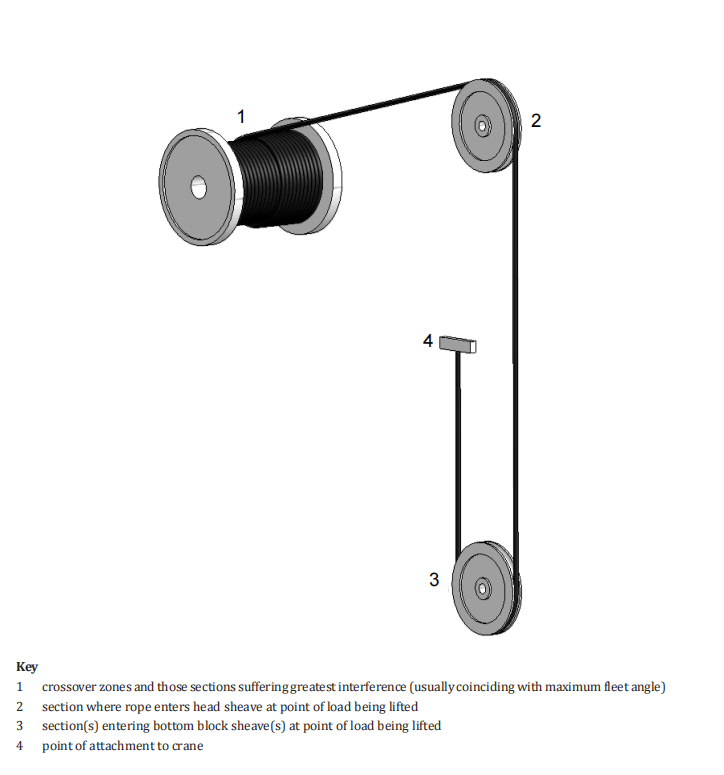

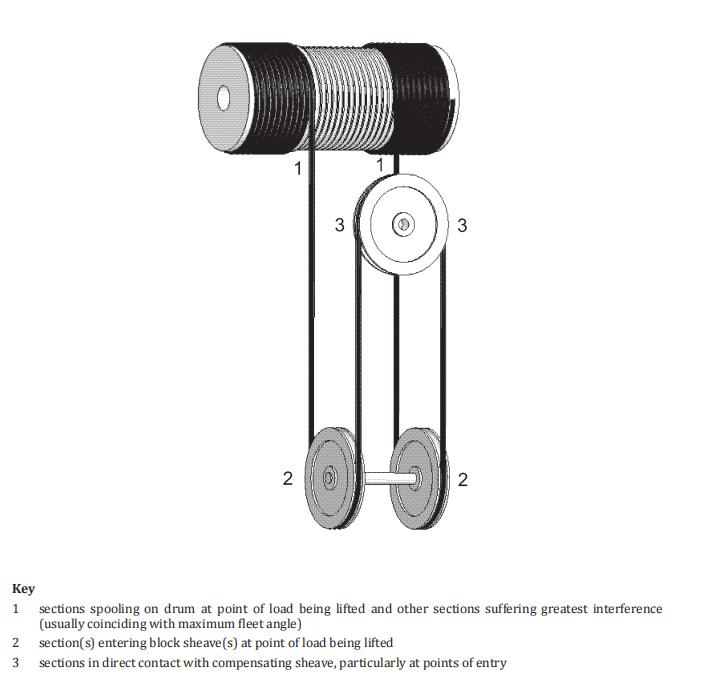

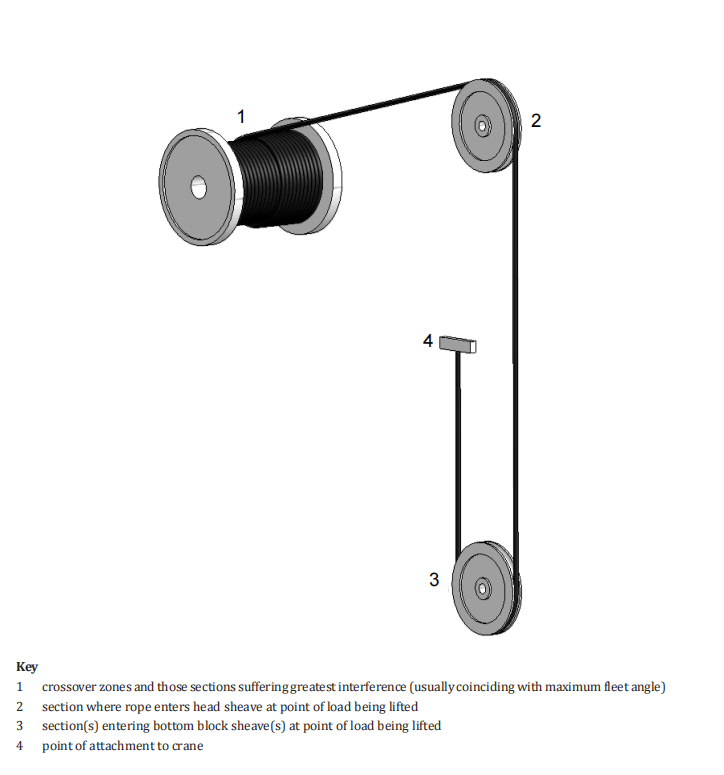

Particular care shall nevertheless be taken at the following wire rope inspection checklist:

- a) drum anchorage;

- b) any section at, and in the vicinity of, a rope termination;

- c) any section that travels through one or more sheaves;

- d) any section that travels through a safe load indicator which incorporates sheaves;

- e) any section that travels through the hook block;

- f) in the case of cranes performing a repetitive operation, any part of the rope that lies over a sheave while the crane is in a loaded condition;

- g) that part of the rope which lies over a compensating sheave;

- h) any section that travels through a spooling device;

- i) those sections that spool on the drum, particularly crossover zones that are associated with multilayer spooling;

- j) any section that is subjected to abrasion by external features (e.g. hatch combings);

- k) any part of rope that is exposed to heat.

NOTE :For areas requiring particularly close inspection,see the follow picture.

2.4 Record of periodic inspection

After each periodic inspection, the competent person shall provide a rope inspection record , and state the maximum time interval that is not to be exceeded before the next periodic inspection takes place.

Preferably, a running record, should be maintained.

For wire rope inspection form please download ISO4309-2017 to see appendix E.

3.Special cases inspection of wire ropes

3.1 Inspection following an incident

If an incident has occurred that might have caused damage to a rope and/or its termination, the rope and/or its termination shall be inspected as for a periodic inspection , prior to recommencement of work or as required by the competent person.

NOTE: Where a twin rope hoisting system is employed, it is often necessary to replace both ropes even if only one has reached discard, because the new rope is larger than the one remaining and has a different elongation property, which can both have an effect on the respective amounts of rope being paid out from the drum.

3.2 Inspection following period with crane out of operation

If the crane has been out of operation for more than three months, the rope(s) shall undergo a periodic inspection, as described in periodic inspection, prior to recommencement of work.

4.Wire rope discard criteria

4.1Visible broken wires

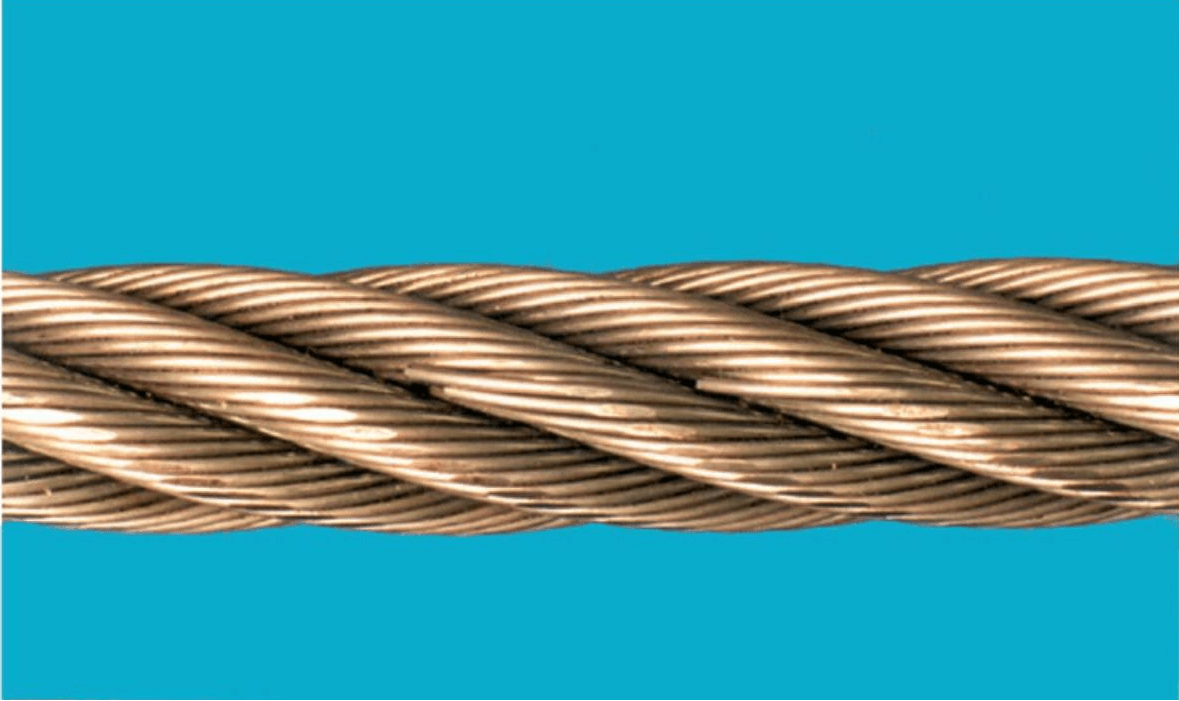

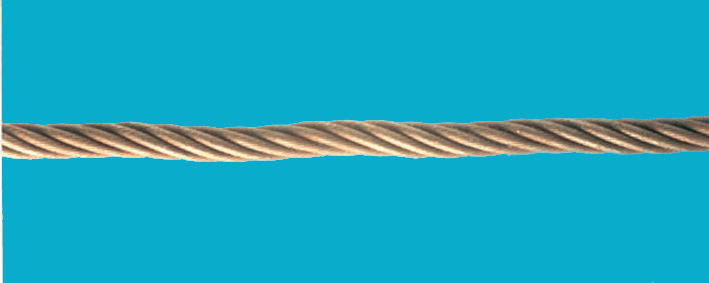

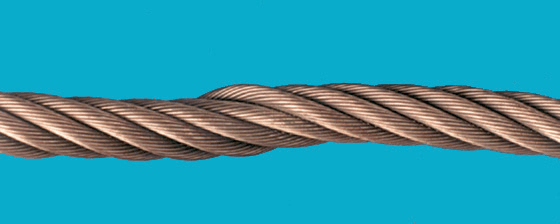

Crown wire breaks

Crown wire breaks

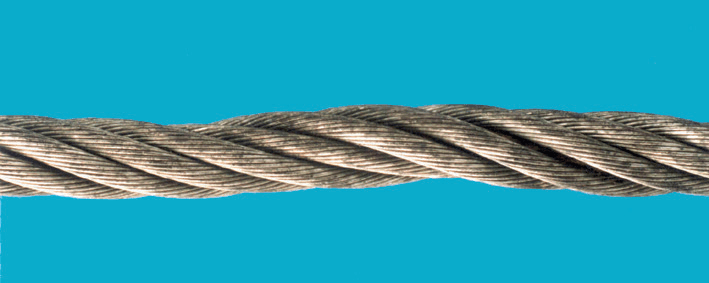

Valley wire breaks

Valley wire breaks

4.2 Decrease in rope diameter

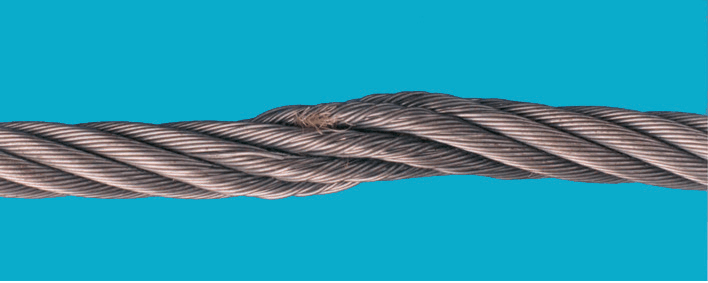

Local reduction in rope diameter (sunken strand)

Local reduction in rope diameter (sunken strand)

4.3 Fracture of strands

If a complete strand fracture occurs, the rope shall be immediately discarded.

If a complete strand fracture occurs, the rope shall be immediately discarded.

4.4 Corrosion

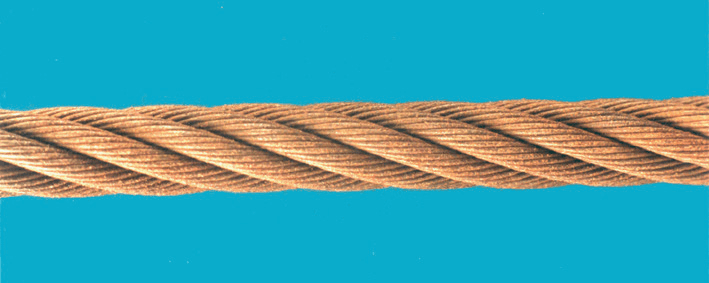

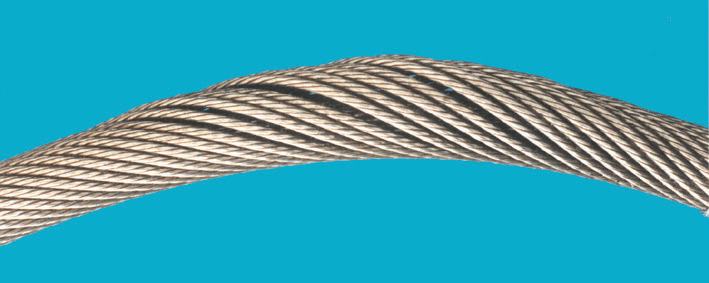

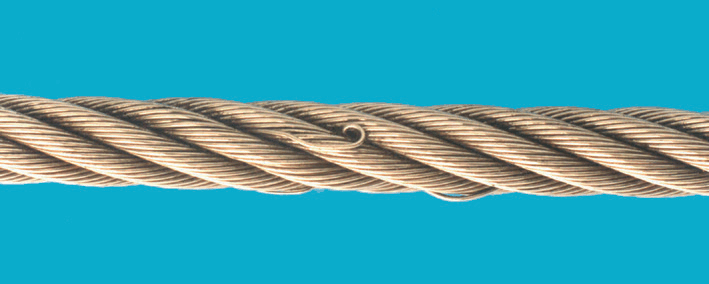

External corrosion: Signs of surface oxidation but can be wiped clean.

External corrosion: Signs of surface oxidation but can be wiped clean.

Wire surface rough to touch, heavily pitted and slack wires.

Enlargement of External corrosion

Enlargement of External corrosion

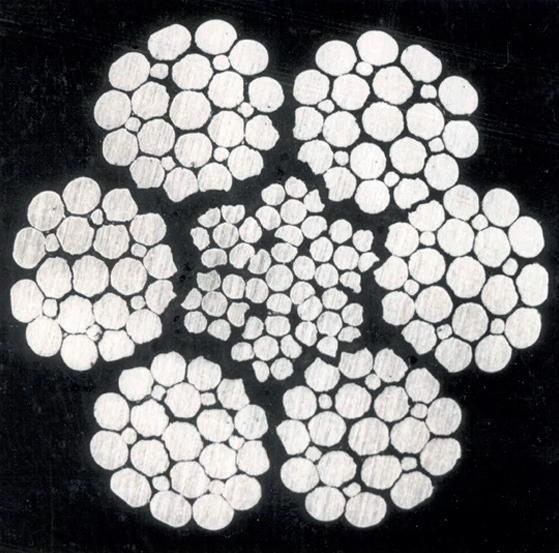

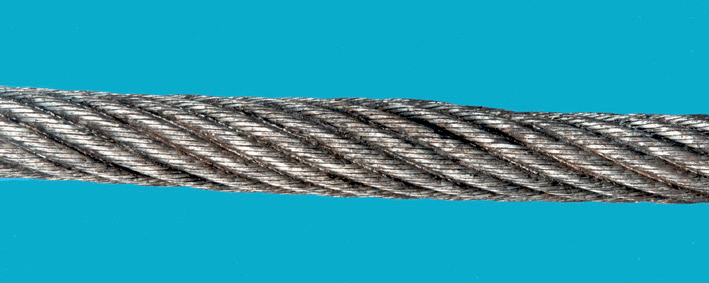

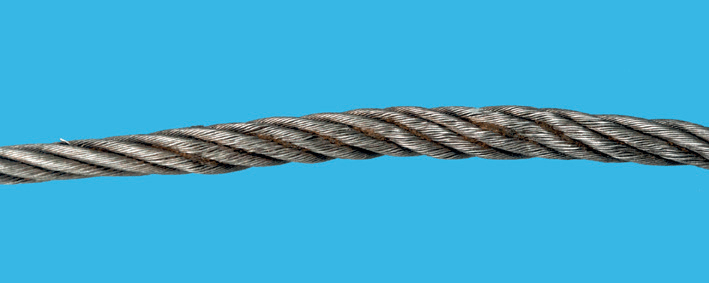

Internal corrosion: Obvious visible signs of internal corrosion.

Internal corrosion: Obvious visible signs of internal corrosion.

corrosion debris exuding from the valleys between the outer strands.

4.5 Deformation and damage

Visible distortion of the rope from its normal shape is classified as deformation. It usually results in an uneven stress distribution in the rope in the area of the deformation, often found to be localized.Deformation and damage can manifest themselves in a number of ways.

Waviness

Waviness

Basket deformation

Basket deformation

Ropes with a basket or lantern deformation shall be immediately discarded or, provided the remaining length of rope is in a serviceable condition, have the affected section removed.

Core protrusion — Single-layer rope

Core protrusion — Single-layer rope

Protrusion of inner rope of rotation-resistant rope

Protrusion of inner rope of rotation-resistant rope

Strand protrusion/ distortion

Strand protrusion/ distortion

Wire protrusion

Wire protrusion

Ropes with protruding wires, usually occurring in groups on the opposite side of the rope to that which is in contact with a sheave groove, shall be immediately discarded.

Local increase in rope diameter due to core distortion

Local increase in rope diameter due to core distortion

If the rope diameter increases by 5 % or more for a rope with a steel core or 10 % or more for a rope with a fibre core during service, the reason for this shall be investigated and consideration given to discarding the rope.

Flattened portion(1)

Flattened portion(1)

Flattened portions of rope which run through a sheave are likely to deteriorate more quickly and

exhibit broken wires. In such cases, but depending on the extent of the flattening, consideration may be given to discarding the rope.

Flattened portions of rope in standard rigging can suffer a greater degree of corrosion than other no affected portions, more so when the outer strands open up and allow ingress of moisture. If retained in service, they shall be inspected more frequently; otherwise, consideration should be given to discarding the rope.

Flattened portion(2)

Flattened portion(2)

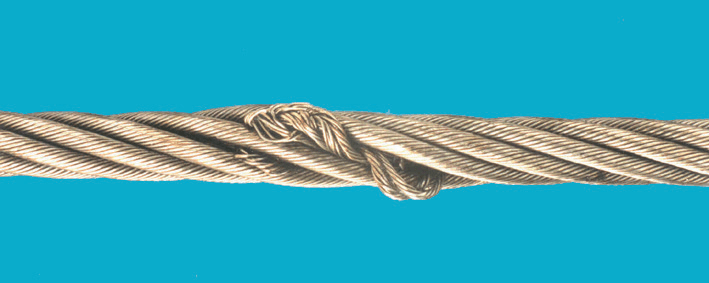

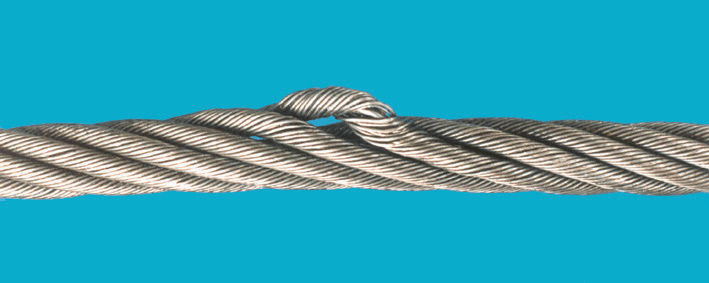

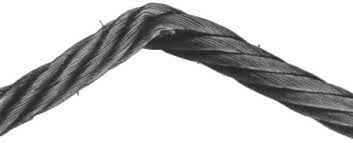

Kink (positive)

Kink (positive)

Ropes with a kink or tightened loop shall be immediately discarded.

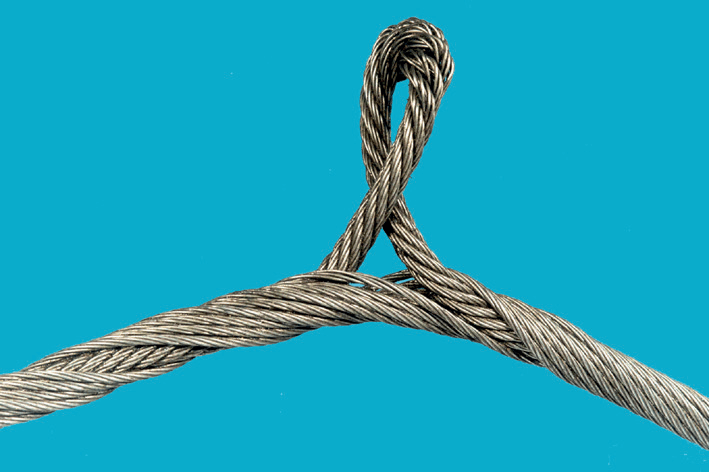

Kink (negative)

Kink (negative)

Kink

Kink

Bend in rope

Portions of rope with a severe bend which run through a sheave are likely to quickly deteriorate and exhibit broken wires. In such cases, the rope shall be immediately discarded.

If the degree of bend is not considered to be severe and the rope is retained in service, it shall be

inspected more frequently; otherwise, consideration should be given to discarding the rope.

Damage due to heat or electric arcing

Damage due to heat or electric arcing

Ropes that are not normally operated at temperature, but have been subjected to exceptionally high thermal effects, externally recognizable by the associated heat colors produced in the steel wires and/or a distinct loss of grease from the rope, shall be immediately discarded.

If two or more wires have been affected locally, due to electric arcing, such as that resulting from

incorrectly grounded welding leads, the rope shall be discarded. This can occur at the point where the current enters or leaves the rope.

For the specific scrap standards of different types of wire rope please download ISO 4309-2017.

Reference:Care and Maintenance of Wire Ropes:6 Things You Must Know