Gantry Crane Installation: Complete Details for Smooth Installation

Table of Contents

In modern manufacturing and construction industries, gantry cranes play a crucial role as highly efficient lifting equipment. Proper installation not only ensures the normal operation of the equipment but also significantly enhances work efficiency and safety. This guide will provide a detailed overview of the gantry crane installation process, key considerations, and solutions to common issues, helping you successfully complete the installation and ensure optimal performance in various environments. Whether you are an experienced professional or a first-time user, this guide will offer practical advice and in-depth insights.

Tools Required for Crane Installation

The selection and use of tools are crucial during the installation of gantry cranes. The right tools not only improve work efficiency but also ensure the safety and accuracy of the installation process. For example, wrenches and hydraulic jacks are essential for tightening and adjustments, while welding machines are important for connecting structural components. A lack of necessary tools can lead to improper installation, even resulting in safety accidents. Therefore, having a complete set of tools is essential for high-quality installation, ensuring that each step proceeds smoothly and laying a solid foundation for safe operations afterward.

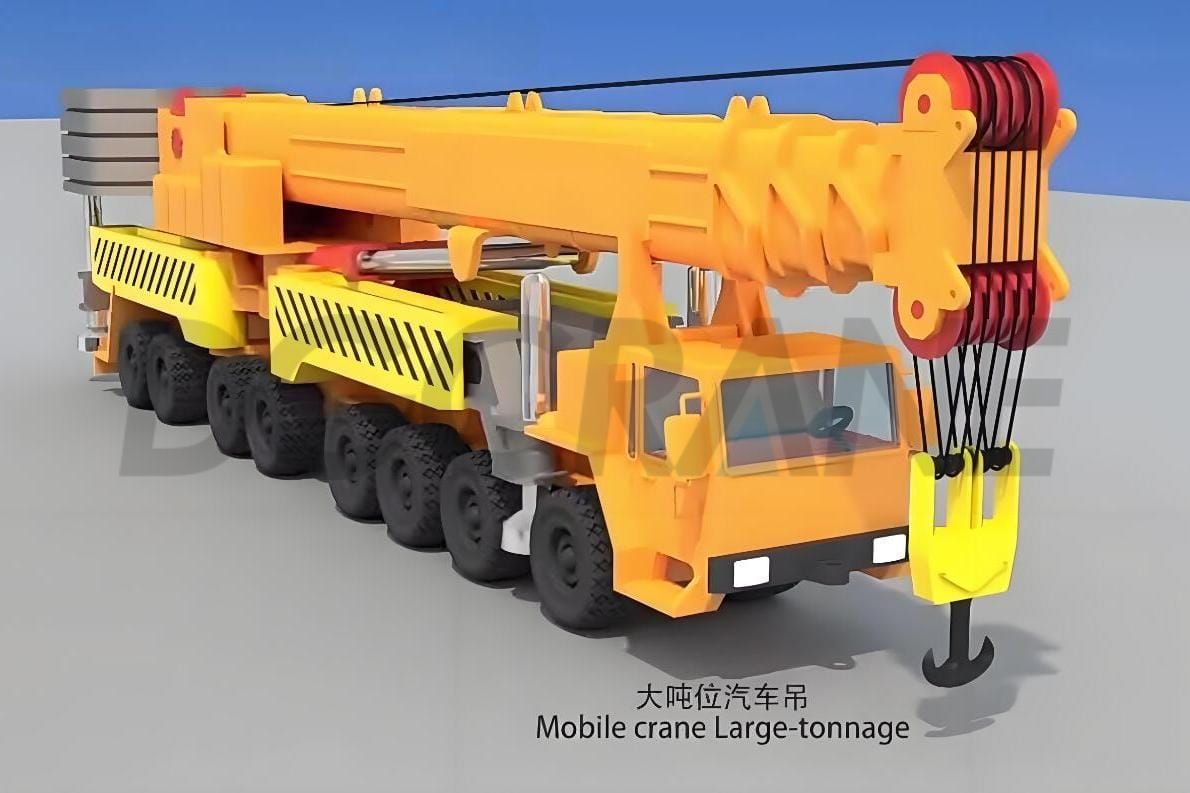

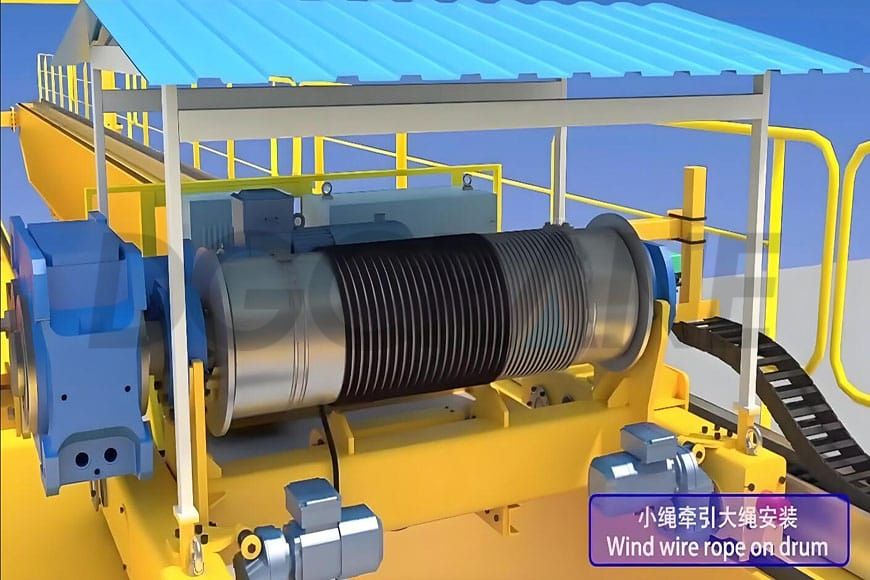

Typically, the following tools are required for gantry crane installation: wrenches, gear oil, welding machines, hydraulic jacks, hand winches, steel tapes, pulling ropes, steel wire ropes for lifting, steel wire rope pulling sleeves, auxiliary installation tools for legs, leg installation platforms, forklifts, small-tonnage truck cranes, and large-tonnage truck cranes.

Gantry Crane Installation

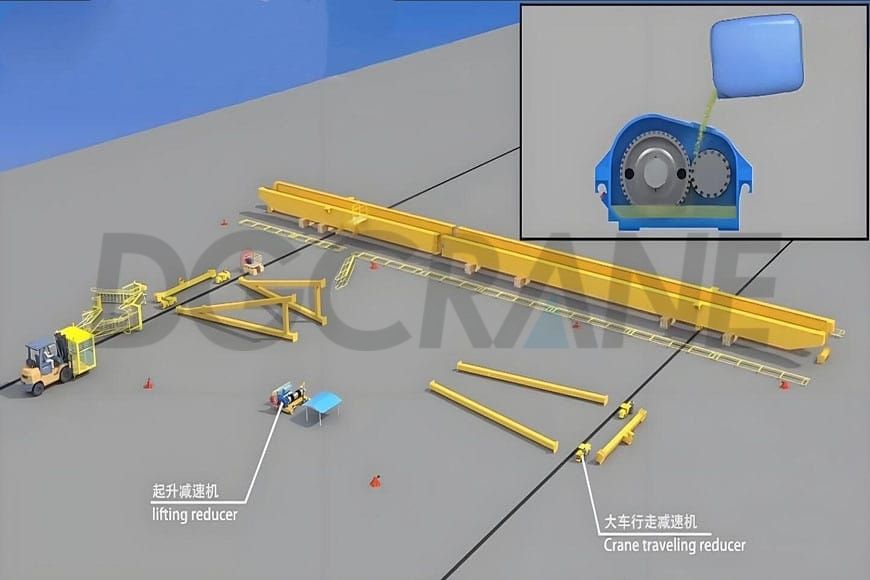

Add gear oil to the reducer before installation

- Lubrication: Gear oil effectively lubricates the gears and bearings inside the reducer, reducing friction and wear, thus extending the service life of the reducer.

- Heat dissipation: Lubricating oil helps dissipate the heat generated during the operation of the reducer, maintaining it within the normal working temperature range and preventing overheating.

- Rust prevention: Gear oil forms a protective film on metal surfaces, preventing moisture and oxidation, thus reducing the risk of rust.

- Cleanliness: High-quality gear oil helps remove impurities and dirt from inside the reducer, keeping the internal components clean and ensuring proper operation.

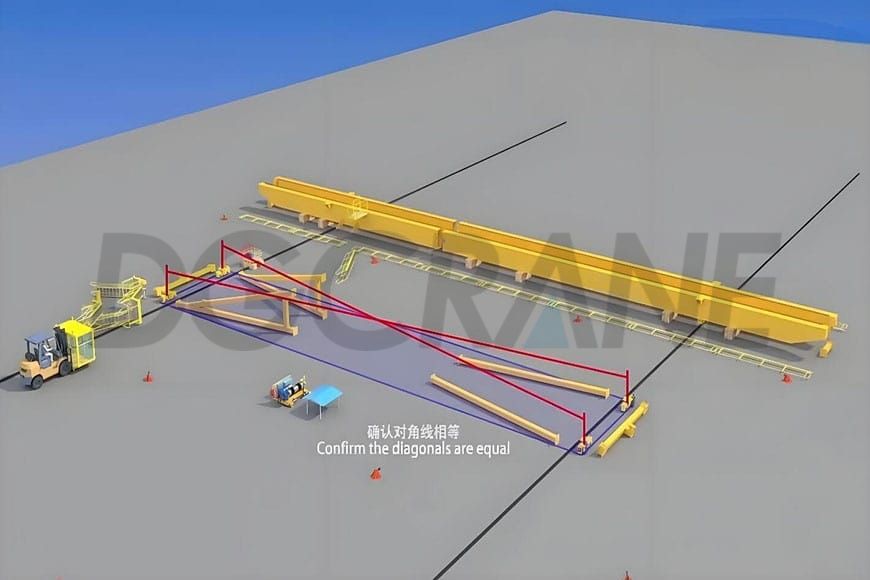

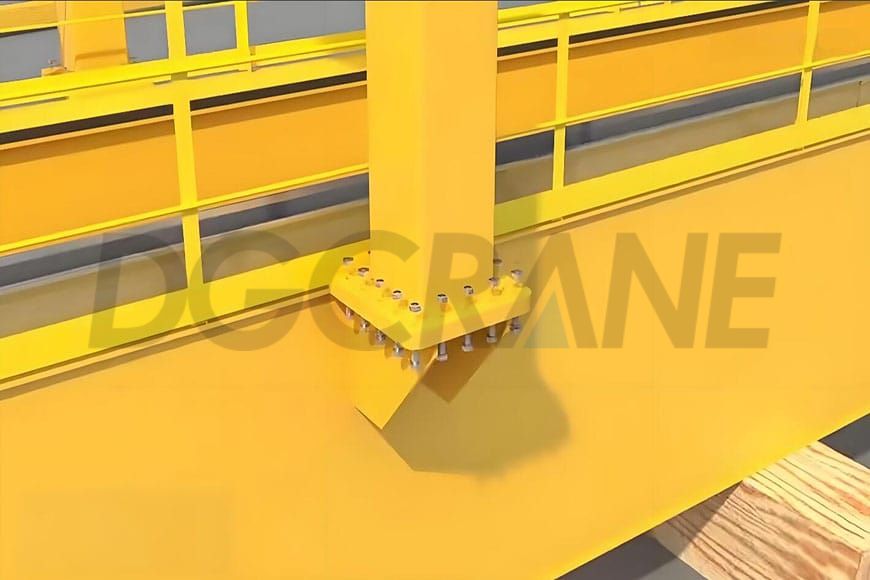

Calculate the crane installation position and ensure equal diagonal measurements

- Ensure levelness: Confirming that the diagonals are equal is an effective method to check if the foundation is level. Only a level installation can ensure the crane’s stability and prevent tilting or imbalance during operation.

- Enhance safety: An imbalanced installation can lead to the risk of the crane tipping over or falling during use. Therefore, ensuring equal diagonals helps improve overall safety and reduce the likelihood of accidents.

- Optimize operational efficiency: A level and symmetrical installation position allows the crane to distribute loads more efficiently during operation, improving its operational efficiency and reducing the likelihood of mechanical failures.

- Extend equipment lifespan: Improper installation may cause excessive wear and component damage. Confirming that the diagonals are equal ensures an even distribution of forces across all parts, which helps extend the crane’s lifespan.

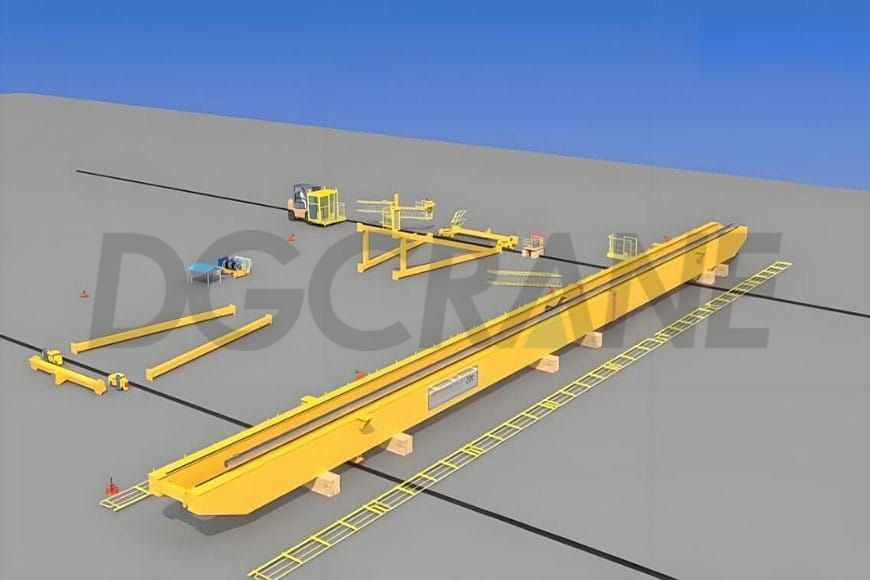

Ground Installation Phase

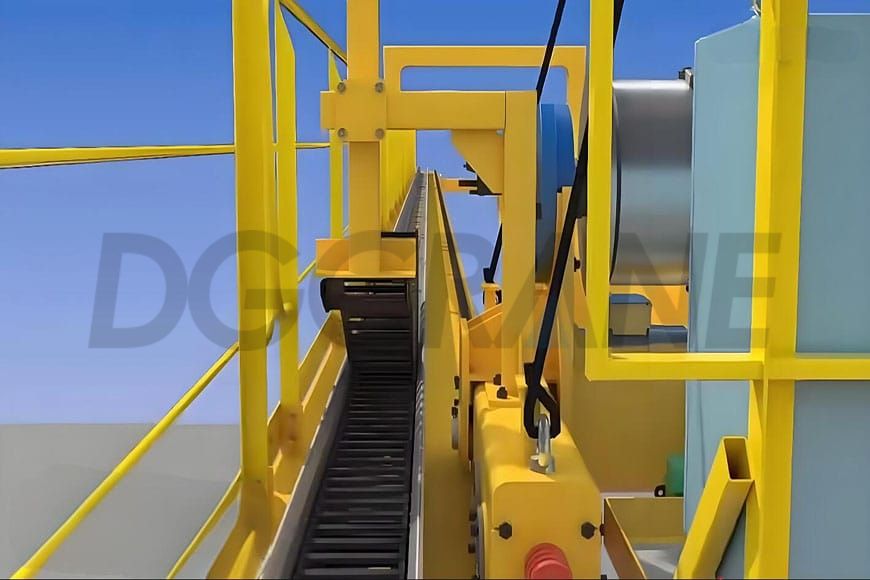

Low-altitude Lifting Phase

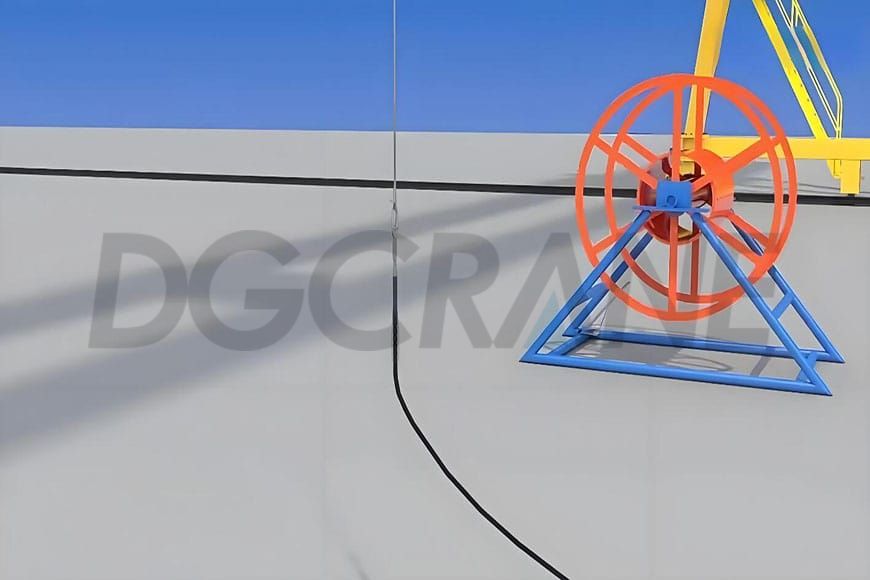

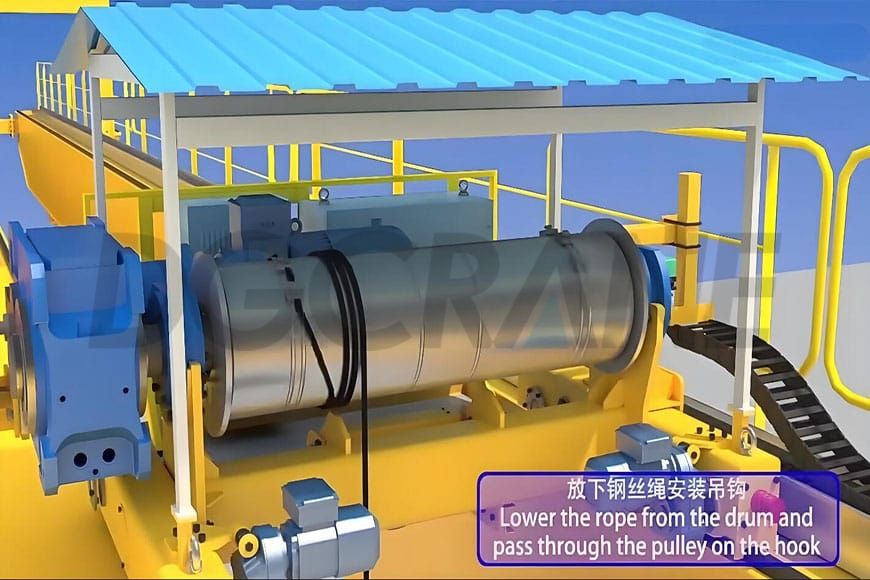

Wire Rope and Hook Installation Phase

Installation Complete

When you purchase our gantry crane, you not only get exceptional equipment but also benefit from professional on-site installation services to ensure the equipment is quickly and safely put into use. Additionally, we offer flexible remote guidance services, with technical experts available online throughout the process to help you easily resolve any installation issues. Whichever option you choose, we provide you with worry-free and reliable installation support to help your project progress smoothly.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!