Crane Hand Signals for Overhead and Gantry Crane

In industrial settings where overhead cranes and gantry cranes are utilized, it is crucial to have a clear and effective communication system between the crane operator and the signal person. While technology has provided advancements in remote control systems, understanding and using hand signals remain an essential part of crane operations. In this article, we will explore the significance of mastering crane hand signals and how they contribute to ensuring safe and efficient lifting operations.

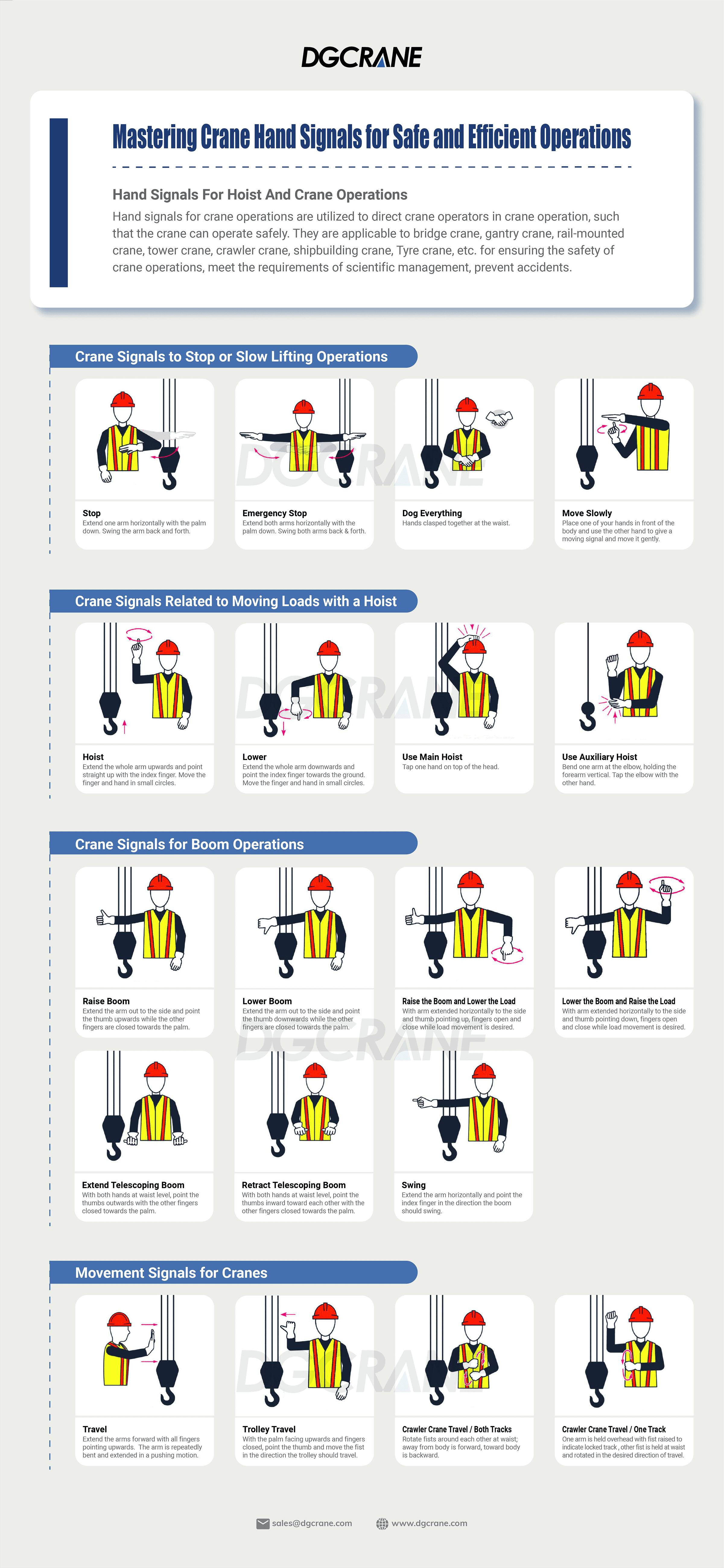

Part 1: Crane Signals to Stop or Slow Lifting Operations

When it comes to stopping or slowing down lifting operations, specific hand signals are used to communicate with the crane operator. These signals include:

- Stop: The signal is used to halt all crane operations immediately. When the ground personnel extends their arm horizontally with the palm facing downward, it indicates that the crane operator should stop all movements.

- Emergency Stop: In critical situations requiring an immediate halt of all operations, the signal is used. The ground personnel will repeatedly swing their raised arm in a horizontal motion, signaling the need for an emergency stop.

- Dog Everything: The signal instructs the crane operator to secure or lock all crane functions. The ground personnel will form a closed fist with their hand and move it in a circular motion, indicating that all crane movements should be locked.

- Move Slowly: When a slower movement is necessary, the signal is employed. The ground personnel will extend their arm horizontally with the palm facing downward and make a slow, waving motion. This indicates that the crane operator should reduce the speed of all movements.

These signals are crucial in situations where precision and caution are required, such as when approaching obstacles, positioning loads, or during critical phases of the lifting process.

Part 2: Crane Signals Related to Moving Loads with a Hoist

When moving loads with a hoist, the signal person communicates the desired actions to the crane operator using specific hand signals. These signals include:

- Hoist: Clench both hands and move them upward simultaneously. This signal instructs the operator to engage the hoist and begin lifting the load.

- Lower: Extend one arm vertically with the palm facing downward and move it upward and downward in a repeated motion. This signal indicates the need to lower the load.

- Use Main Hoist: The signal is used to instruct the crane operator to utilize the primary hoist. The ground personnel will form a closed fist and extend their arm outward, indicating the use of the main hoist function.

- Use Auxiliary: When the auxiliary hoist is required for lifting operations, the ground personnel will extend their arm outward with the thumb raised, signaling the crane operator to utilize the auxiliary hoist.

Clear and precise communication through these signals ensures that the load is moved safely and accurately, preventing accidents or damage to the load and surrounding equipment.

Part 3: Crane Signals for Boom Operations

During boom operations, where the crane’s arm or boom is utilized, specific hand signals are employed to indicate the desired movements. These signals include:

- Raise Boom: The signal instructs the crane operator to elevate the boom. The ground personnel will extend their arm vertically and make a slow, upward motion, imitating the movement of raising the boom.

- Lower Boom: To indicate the need for lowering the boom, the ground personnel will extend their arm vertically and make a slow, downward motion, resembling the movement of lowering the boom.

- Raise the Boom and Lower the Load: When both raising the boom and lowering the load are required simultaneously, the ground personnel will extend one arm upward and the other arm downward, making distinct vertical motions to convey the specific instructions.

- Lower the Boom and Raise the Load: Conversely, to lower the boom and raise the load simultaneously, the ground personnel will extend one arm down and the other arm upward, performing clear vertical motions to communicate the necessary actions.

- Extend Telescoping Boom: For cranes equipped with telescoping booms, the ground personnel will extend their arms outward in opposite directions, illustrating the extension of the telescoping boom.

- Retract Telescoping Boom: When the telescoping boom needs to be retracted, the ground personnel will bring their extended arms together, mimicking the movement of retracting the telescoping boom.

- Swing: The signal indicates the need for the crane operator to rotate the crane’s superstructure. The ground personnel will extend their arm horizontally and make a circular motion, indicating the desired direction of the swing.

Mastering these hand signals is essential for safe and efficient boom operations, especially when precise positioning or navigating obstacles is required.

Part 4: Movement Signals for Cranes

Apart from specific lifting and boom operations, hand signals are also used to communicate the general movements of the crane. These signals include:

- Travel: To instruct the crane operator to move the entire crane, the ground personnel will extend their arm horizontally and point in the desired direction of travel.

- Trolley Travel: For overhead cranes with trolley movement, the ground personnel will extend their arm horizontally and move it in a horizontal back-and-forth motion, imitating the movement of a trolley.

- Crawler Crane Travel/Both Tracks: In the case of crawler cranes with tracks, the ground personnel will extend their arms outward and move them in a circular motion, signifying the need for travel using both tracks.

- Crawler Crane Travel/One Track: When a crawler crane needs to travel using only one track, the ground personnel will extend one arm outward and keep the other arm close to their body, indicating the desired direction of travel.

These signals are crucial for maintaining safe distances, avoiding collisions, and ensuring overall control and coordination during crane operations.

Conclusion

Mastering crane hand signals is essential for maintaining a safe working environment in industries that utilize overhead and gantry cranes. Effective communication between the signal person and the crane operator significantly reduces the risk of accidents, enhances productivity, and ensures precise positioning of loads. Safety should always be a top priority in industrial operations, and the proper use of hand signals contributes to achieving that goal.

Remember, by understanding and following the hand signals discussed in this article, we can promote a culture of safety and ensure the smooth and efficient operation of overhead and gantry cranes.

FAQs

Q: Why is it important to master crane hand signals?

A: Mastering crane hand signals is crucial for effective communication between the signal person and the crane operator, ensuring safe and efficient lifting operations.

Q: Are hand signals still relevant in the age of remote-controlled cranes?

A: While technology has advanced, hand signals remain a vital backup communication method and a necessary skill for crane operators and signal persons.

Q: What should I do if I am unsure about a hand signal?

A: If you are uncertain about a hand signal or its meaning, always clarify with the signal person or the crane operator before proceeding with any movements.

Q: How can I ensure proper understanding and coordination when using hand signals?

A: Regular training, clear communication protocols, and ongoing practice sessions between the signal person and crane operator are key to ensuring proper understanding and coordination of hand signals.

Q: Are there any industry standards for crane hand signals?

A: Yes, various industry organizations, such as OSHA, ANSI, and ASME, provide guidelines and standards for crane hand signals that should be followed for safe operations.