Closer Look Gantry Crane Common Failures: 10 Components Must be Checked

Gantry crane inspections are a critical step in ensuring safe operation and prolonging the life of your equipment. Here will show you some examples of failures that you will encounter inside the safety inspection process of gantry cranes so that you can quickly understand these failures and promptly correct possible potential safety hazards.

Catalog

- Inspection of the rails section and examples of failures

- Inspection of steel structure section and examples of failures

- Inspection of crane running parts and examples of failures

- Inspection of hoisting/winch trolley and examples of failures

- Inspection of hoist and examples of failures

- Inspection of hooks and ropes inspection and examples of failures

- Inspection of electrical parts and examples of failures

- Inspection of ancillary structure and examples of failures

- Inspection of safety devices

- Inspection of field use and examples of failures

1. Inspection of Rails Section & Examples of Failures

- Check the gantry crane rail foundation for settlement, breaks, and cracks.

- Check the rail for cracks, severe wear, and other defects.

- Check the contact situation of the rails and rails foundation, and shall not be suspended from the foundation.

- Check whether the rail joints meet the requirements, generally 1-2MM, and 4-6MM are appropriate for cold areas.

- Check the rail transverse dislocation and height difference, the requirement is not more than 1MM.

- Check the fixing situation of the rails, the pressure plate and bolts should not be missing, and the pressure plate and bolts should be tight and meet the requirements.

- Check the connection of the rail’s connection plate.

- Check whether the longitudinal slope of the rails meets the design requirements, generally 1‰. The whole length is not greater than 10MM.

- The height difference of the same cross-section track is not more than 10MM.

- Check whether the rail gauge is super deviation, the deviation of the track gauge of the big car is required to be no more than ±15MM, or according to the parameters of the gantry crane instruction manual to determine.

The joint surface between the traveling track of the gantry crane and the track foundation should be close

The joint surface between the traveling track of the gantry crane and the track foundation should be close

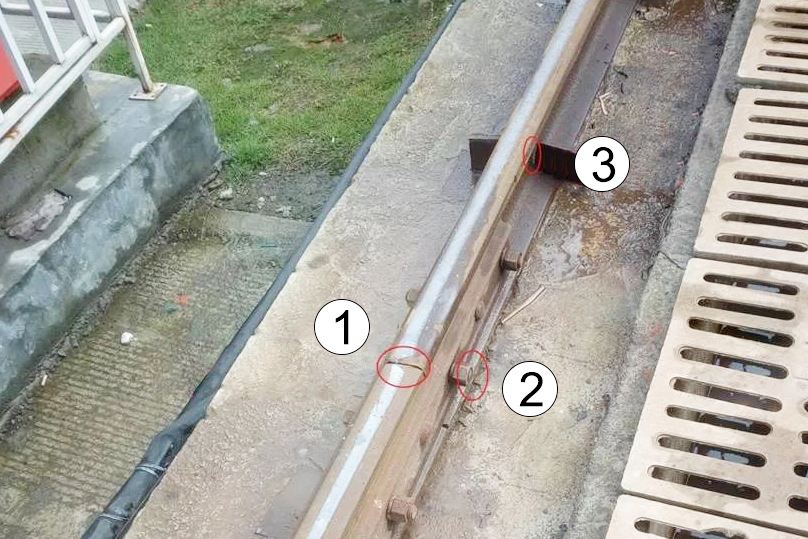

1. Two sections of rail joints are uneven, left and right misalignment.

1. Two sections of rail joints are uneven, left and right misalignment.

2. No flat washers on the bolts of the rail connection plate, and the threads of the bolts are exposed too little, and not standardized.

3. Fixed plate is not close to the steel web.

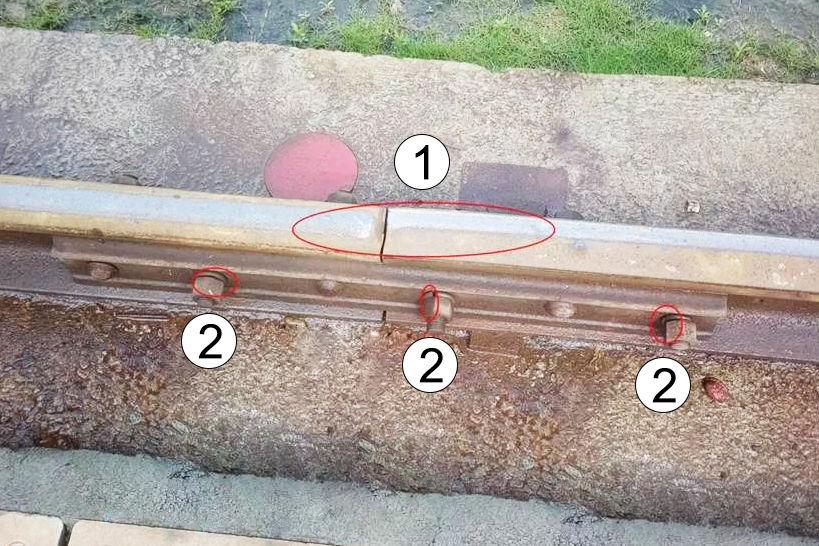

1. From the point of view of the running track of the traveling wheels of the gantry, there are problems with the laying of the two rails, and the levelness does not meet the requirements.

1. From the point of view of the running track of the traveling wheels of the gantry, there are problems with the laying of the two rails, and the levelness does not meet the requirements.

2. There is wear and tear at the connection of the two rails, and there are problems with the fixing bolts of the connecting plate between the two rails, with no washer and damaged spring washers.

Problems with joint clearance between rails.

Problems with joint clearance between rails.

Problems with both rail joints, and both rail joint plate fixing bolts.

Problems with both rail joints, and both rail joint plate fixing bolts.

Uneven joints in rails

Uneven joints in rails

Most of the failures of the track and foundation appear in the installation process of the gantry crane, so in the installation, pay special attention to this aspect, so as to avoid larger problems in the later stage.

2. Inspection of Steel Structure Section & Examples of Failures

- Check the tightness of the connecting bolts of the outrigger flange of the gantry crane.

- Check the bonding of the connecting plane of the outrigger flange.

- Check the weld of the outrigger connecting the flange and the outrigger pipe column.

- Check whether the pin of the outrigger connecting rod is normal, whether the connecting bolts are tightened, and whether the connecting ear plate of the rod is welded with the outrigger.

- Check the tightness of the connecting bolts between the lower crossbeam of the outrigger and the outrigger and the connecting bolts between the lower crossbeams.

- Check the welding of the lower crossbeam of the outrigger.

- Check the tightness of the connecting bolts between the upper crossbeam of the outrigger the outrigger and the main beam.

- Check the welds on the upper crossbeam of the outrigger and the welded parts.

- Check the connection condition of the main beam connection parts, including the fastening condition of the pin or connection bolts, the deformation condition at the connection joints, and the condition of the weld seam at the connection joints.

- Check the welding seam condition of each welding place of the main girder, and pay attention to the welding seam of the upper and lower chords of the main girder and the web rod to see if there is any tearing.

- Check whether there is a deformation of the main girder as a whole and whether the deformation is within the specification.

- Check whether there is a large height difference between the left and right main girders and whether it is within the specification.

- Check whether the cross-link between the left and right main girders is connected normally, and check the welding seam of the connecting ear plate of the cross-link.

The layout of the leg connection bolts is not standardized, and it is not convenient for installation and disassembly.

The layout of the leg connection bolts is not standardized, and it is not convenient for installation and disassembly.

Flange The plate surface is warped and not straightened.

Cracked welds and severe deformation at the top of the support

Cracked welds and severe deformation at the top of the support

3. Inspection of Crane Running Parts & Examples of Failures

- Check the wear and cracking of the traveling wheel, whether there is serious deformation, whether there is serious wear of the wheel rim or no wheel rim, etc..

- Check whether the reducer lubricant is sufficient and the quality of the lubricant.

- Check the reducer case for cracks and oil leakage.

- Check the fixing condition of the reducer.

- Check whether the brake works normally.

- Check the brake clearance of the brake, the wear of the brake pads, and the wear of the brake wheel.

- Check the connection of the coupling, the tightness of the connecting bolts, and the wear of the elastic connecting parts.

- Check the tightness and protection of the motor.

The reduction gearbox should be in good condition, with no crash cracks, etc.

The reduction gearbox should be in good condition, with no crash cracks, etc.

Poor sealing of the gearbox oil injection port, resulting in oil leakage.

Poor sealing of the gearbox oil injection port, resulting in oil leakage.

Wheel tread metal fatigue spalling

Wheel tread metal fatigue spalling

4. Inspection of Hoisting/Winch Trolley & Examples of Failures

- Check the wear and cracking of the traveling wheels, whether there is serious deformation, and whether there is serious wear of the wheel rim or no wheel rim.

- Check the condition of the running track of the winch trolley, including track joints, wear, and damage.

- Check the lubricating oil condition of the traveling part of the reducer.

- Check the braking condition of the traveling part.

- Check the fixing condition of each part of the traveling part.

- Check the fixing of the rope end of the hoisting wire rope on the hoisting winch.

- Check the lubrication of the hoisting winch gearbox, including the capacity and quality of the lubricant.

- Check whether there is any oil leakage from the hoisting winch reducer and whether there is any damage to the reducer.

- Check the fixation of the gearbox.

- Check whether the brake of the hoisting winch is working normally.

- Check the brake clearance of the brake, the wear of the brake pads, and the wear of the brake wheel.

- Check the connection of the coupling, the tightness of the connecting bolts, and the wear of the elastic connecting parts.

- Check the tightness and protection of the motor.

- For the hydraulic braking system, check whether the hydraulic pump station works normally, whether there is oil leakage, and whether the braking pressure meets the requirements.

- Check the wear and protection of the pulleys.

- Check the fastening of each part.

Lock nut not locked

Lock nut not locked

Check the brake module and brake wheel for wear and tightness of the bolts

Check the brake module and brake wheel for wear and tightness of the bolts

Check the height limiters to verify that the hook set stops properly at the upper and lower limit positions

Check the height limiters to verify that the hook set stops properly at the upper and lower limit positions

5. Inspection of Hoist & Examples of Failures

- Check the connection between the running rail of the electric hoist and the main beam and the wear and tear of the rail.

- Check the connection of the running rail, including whether the connecting plate and connecting bolts are tight, and whether the rail connecting seam meets the operation requirements.

- Check the wear and tear of the walking wheel of the electric hoist and whether the clearance between the walking wheel and the rail web meets the safety requirements.

- Check the winding condition of the hoisting wire rope on the electric hoist.

- Check whether the wire rope discharge device of the electric hoist works normally or is damaged.

- Check the working condition of the brake of the electric hoist and the wear of the brake pads, whether the brake clearance and braking force meet the requirements.

- Check the fixation of the wire rope end on the electric hoist.

- Check the tightness of the connection bolts of each connection part.

The electric hoist rope guide has been damaged, resulting in a disorderly arrangement of the wire rope

The electric hoist rope guide has been damaged, resulting in a disorderly arrangement of the wire rope

6. Inspection of Hooks and Ropes & Examples of Failures

- Check the hook for wear and tear.

- Check the configuration of the hook sealer and its damage.

- Check the operation of the hook sheave, wear and tear, and the presence of a device to prevent the wire rope from jumping out of the groove.

- Check the lubrication of moving parts.

- Check the use condition of the wire rope, whether there is checking the deformation situation, such as knotting, extrusion deformation, cut, broken strand, corrosion, high-temperature blackening, rope diameter thinning, and so on.

- Check the fixing condition of the rope end of the wire rope.

Poor lubrication of the surface of the wire rope should be oiled in time

Poor lubrication of the surface of the wire rope should be oiled in time

Look for cracks/cracks and other damage to the pulleys

Look for cracks/cracks and other damage to the pulleys

7. Inspection of Electrical Parts & Examples of Failures

- Check each part of the cable line for damage, hanging objects, support connection is not secure.

- Check whether each motor protective cover is complete and intact.

- Check whether the appearance of each motor is complete and undamaged, whether the junction box and cover should be intact, whether the wire terminals are fastened, and whether there is any broken and fractured wire.

- Check whether each limit switch is complete and intact.

- Check whether the lighting is intact.

- Check the protection of the control cabinet.

- Check the components and electric lines in the control cabinet.

- Check the electrical components in the operation room are intact.

- Check whether the main cable cable reel is working normally.

- Check whether the cable slide rail of the overhead crane is normal and whether the cable moves normally on the slide rail when the crane is running.

- Check whether the cable slide of the electric hoist is working normally and whether the cable moves normally on the slide when the electric hoist is running.

- Check the cable connector of the brake and whether the cable is good or bad.

Wires should be routed into conduits

Wires should be routed into conduits

The insulating shield of the operating handle is missing, there is a danger of electric shock, which must be dealt with in time.

The insulating shield of the operating handle is missing, there is a danger of electric shock, which must be dealt with in time.

Lighting fixture wires need to be laid in conduits, lamps lack lamp holder support

Lighting fixture wires need to be laid in conduits, lamps lack lamp holder support

Trolley cables being checked

Trolley cables being checked

Check whether the tow rope is fixed firmly

Check whether the tow rope is fixed firmly

Cable trolley wheels must be flexible and regularly lubricated

8. Inspection of Ancillary Structure & Examples of Failures

- Check the fixing of the stairs up and down of the gantry crane.

- Check the fixing of each platform.

- Check the fixing of the handrails on the stairs and platforms.

- Check the fixation of the operation room.

The guards for the trolley rails and trolley drive shafts should be in place in a timely manner

The guards for the trolley rails and trolley drive shafts should be in place in a timely manner

9. Inspection of Safety Devices

- Check the safety devices for the operation of the wagon, including whether the traveling limit switch is installed and works normally, whether the traveling limit block is installed and firm, whether the electric or hydraulic iron boot is installed and works normally according to the requirements, whether the rail clamp is installed and works normally according to the requirements.

- Check whether the trolley running deviation correction device is installed and working normally.

- Check whether the windproof cable is installed.

- Check whether the ground anchor is installed correctly and works.

- Check whether the buffer device for trolley operation is installed.

- Check whether the sound and light alarm device for the operation of the trolley is installed and works properly.

- Check whether the safety devices of the hoisting mechanism are fully equipped and work properly. Including trolley running limit device, limit block, lifting height limiter, and lifting weight limiter.

- Check whether the monitoring system is working normally.

- Check whether the anemometer works normally.

Checking the performance of rail clamps

Checking the performance of rail clamps

Checking the condition of the audible and visual warning devices

Check snubbers, check ropes, check ropes fixing points

Check snubbers, check ropes, check ropes fixing points

The end of the track should be set to limit the car stop, set the travel limit switch collision point, and check the setting of the correct location.

The end of the track should be set to limit the car stop, set the travel limit switch collision point, and check the setting of the correct location.

10. Inspection of Field Use & Examples of Failures

- Check whether there are any obstacles affecting the operation of the gantry crane near the gantry crane track.

- Check whether there are any scattered objects on each platform and truss.

- Check whether there are any obstacles affecting the operation of the gantry crane above and below, left and right of the gantry crane.

There shall be no interfering objects within 1 meter on each side of the traveling track of the big vehicle.

There shall be no interfering objects within 1 meter on each side of the traveling track of the big vehicle.

Insufficient space on both sides of the traveling track of the large vehicle or irregular operation of the transported goods resulted in the speed reducer box having traces of bumping.

Insufficient space on both sides of the traveling track of the large vehicle or irregular operation of the transported goods resulted in the speed reducer box having traces of bumping.

Platforms have loose material that should be cleaned up in a timely manner.

Platforms have loose material that should be cleaned up in a timely manner.

FAQ

Q: How often do Portal Cranes need to be inspected?

A: The frequency of inspection depends on a number of factors, including the type of equipment, workload, operating environment, and regulatory requirements. Typically, daily inspections should be performed once a day or before each use. Periodic inspections can be performed periodically depending on use, usually every three months to a year.

Daily Inspection

- Electrical System: Check electrical wiring, control boxes, buttons, and switches to ensure that everything is functioning properly and that there are no loose wires or connections.

- Mechanical Components: Check various mechanical components, including gears, bearings, wire ropes, pulleys, brakes, etc., to make sure they are not abnormally worn or damaged.

- Lifting Hooks: Check lifting hooks to ensure that they are not cracked, deformed, or damaged and that they are safe and reliable.

- Lubrication: Check lubrication points to ensure that the equipment is adequately lubricated to minimize wear and friction.

- Guards: Check safety devices such as limit switches, safety ropes, emergency stops, etc., to ensure they are working properly.

- Cables and Harnesses: Check cables and harnesses to make sure they are not cracked or frayed to avoid electrical failure.

- Exterior: Check the exterior of the crane, including welded joints, coatings, and markings to ensure there is no corrosion or damage.

Regular Inspections

- Structural Inspection: Conduct regular structural inspections to check for cracks, wear, or deformation of girders, columns, and other major components.

- Lifting Ropes: Regularly inspect lifting ropes for any wear, deformation, or breakage. Lifting ropes are critical safety components and must be maintained in good condition.

- Electrical System: Regularly inspect the electrical system, including cables, switches, contactors, and control systems to ensure they are working properly.

- Braking systems: Check the braking systems to ensure that they reliably stop the crane’s movement.

- Hydraulic system (if applicable): If the gantry crane is equipped with a hydraulic system, regularly check the hydraulic oil, lines, and seals to ensure they are not leaking or damaged.

Take care, however, to ensure compliance with local codes and manufacturer’s recommendations, as some equipment may require more frequent inspections. In addition, if failures are found during routine or periodic inspections, repairs or more detailed inspections should be carried out immediately. Safety is always a primary concern and should not be overlooked.

Q: Where can I download the gantry crane inspection checklist?

A: Because of different crane types/frequency of equipment utilization, etc., the inspection of the equipment can be different, there is no unique checklist, but that’s okay, with the popularity of intelligent equipment, more and more online tools can be utilized, you can customize the Gantry crane inspection checklist template to fit your specific situation, here are the recommendations Here are two tools: SafetyCulture and DataScope, free to register and free to download!

Of course, you can also download this template directly to save you the time of registration.

Gantry Crane Inspection Checklist Template.pdf

In Conclusion

Whether it is a gantry crane or overhead crane, safety is the most important issue, so about the safety inspection are every manager should pay attention to, designate a reasonable daily/monthly/quarterly/annual inspection plan, hope that the lifting equipment in your factory does not have these failures listed above, and always safe production.

DGCRANE is a trader specializing in sales of overhead cranes/gantry cranes and has a lot of experience in trade export. Trade export has rich experience, whether it is pre-sale to customize the lifting solution that suits your needs, or after-sale to solve the failures encountered in the process of use, we will help you to solve them together!

Any questions, contact your dedicated customer service at Zora WhatsApp: +86 15836115029 or email: zora@dgcrane.com now!