Assembly and Installation of Single Girder Overhead Cranes

Overhead Cranes are widely used in various industries for efficient material handling. Single Girder Overhead Cranes, in particular, are popular due to their simplicity, versatility, and cost-effectiveness. In this article, we will guide you through the assembly and installation process of single girder overhead cranes, ensuring a smooth and successful setup.

Assembly and Installation of Single Girder Overhead Cranes

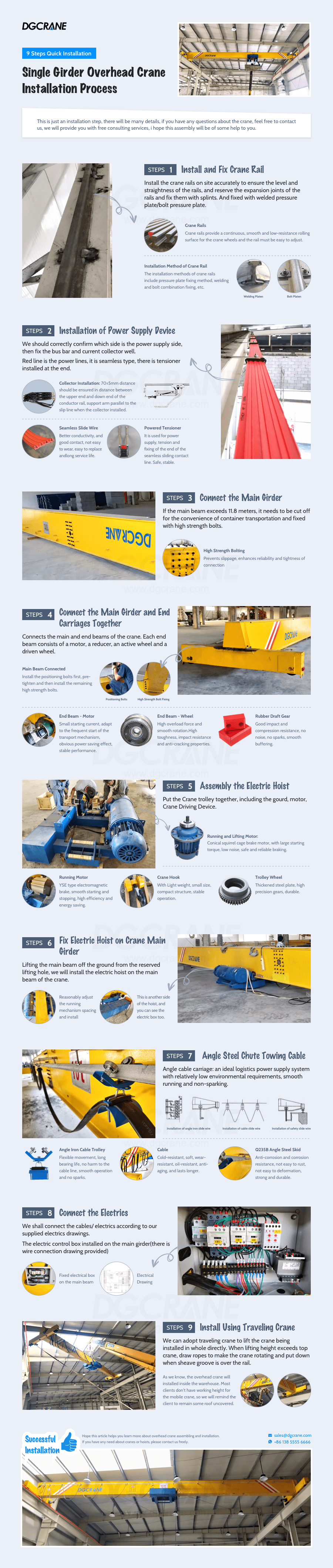

Above all, let’s start with an overview of the Installation Details for a Single Girder Overhead Crane. The procedure is depicted visually in the infographic below. It includes clear illustrations and labels to help you understand each stage of the installation.

Now let’s dive into the step-by-step process of assembling and installing a single girder overhead crane. Follow these guidelines carefully to ensure a smooth and efficient setup:

STEP1: Pre-installation

Before the actual installation of the crane takes place, the pre-installation of cranes needs to be taken. It ensures the site and conditions are suitable for crane installation and makes necessary arrangements for a smooth installation process. The pre-installation phase typically includes the following:

Site Assessment:

- Evaluate the site conditions, including floor space, load-bearing capacity, and overhead clearance.

- Ensure compliance with local regulations and safety standards.

- Verify power availability and suitability for crane operation.

Crane Selection:

- Determine the appropriate crane capacity, span, and lifting height based on the application requirements.

- Choose a reliable crane supplier who offers high-quality single girder overhead cranes.

Foundation Preparation:

- Excavate the foundation according to the manufacturer’s specifications, considering soil conditions and load requirements.

- Ensure accurate alignment and positioning of anchor bolts to match the crane’s base dimensions.

Power and Utilities:

Ensuring that the necessary power supply and utilities are available at the installation site.

STEP2: Assembly and Installation

The process mainly includes but is not limited to the following aspects, and the order can be adjusted according to the practical situation:

- Assembling Components: Begin by unpacking the crane components and assembling them systematically. Check for any damage during transit and report it to the manufacturer if necessary. Ensure that all the necessary parts, including bolts, nuts, and electrical components, are present.

- Install and Fix the Crane Rail: Install the crane rails on site accurately to ensure the level and straightness of the rails. Reserve the expansion joints of the rails and fix them with splints. and fixed with welded pressure plate/bolt pressure plate.

- Installing the End Trucks: Start by installing the end trucks on both ends of the bridge beam. Follow the manufacturer’s instructions for proper alignment and attachment. Ensure that the wheels are properly lubricated and aligned with the runway rail or runway beam.

- Mounting the Beam: Once the end trucks are securely in place, mount the bridge beam on top of them. Use appropriate lifting equipment and follow safe lifting practices to avoid accidents or injuries. Align the beam correctly and secure it tightly to the end trucks using the provided fasteners.

Mounting the beam on site in the Philippines

Mounting the beam on site in the Philippines - Fixing Electric Hoist: With the bridge beam in position, proceed to attach the hoist to the designated location on the beam. Follow the manufacturer’s instructions for proper alignment and connection. Ensure that all electrical connections are made securely and in accordance with safety guidelines.

- Connecting the Trolley: Next, connect the trolley to the bridge beam and ensure smooth horizontal movement along the length of the beam. Double-check all connections and fasteners to avoid any potential issues during operation.

- Electrical Connections: Once the mechanical components are in place, proceed with the electrical connections. Connect the power supply to the hoist and trolley motors, following the provided wiring diagrams. Ensure that all connections are properly insulated and secured.

Connecting the electrics in the Philippines

Connecting the electrics in the Philippines

STEP3: Testing and Final Adjustments

After completing the assembly and electrical connections, thoroughly test the crane’s functionality. The load testing is the most important part. It typically includes the following categories:

- Static Load Testing: This involves testing the crane’s ability to lift and hold a predetermined load without any movement. It verifies the crane’s structural integrity and ensures that it can safely handle the rated load capacity.

- Dynamic Load Testing: This category includes various tests to evaluate the crane’s performance under dynamic conditions. It includes tests such as accelerating, decelerating, and stopping the load to assess the crane’s stability, control, and response to different operational scenarios.

The load testing in Djibouti

The load testing in Djibouti

The specific procedures may vary depending on the crane’s design, capacity, and applicable regulations. Conducting comprehensive load testing ensures the safe and reliable operation of the bridge crane.

Safety Considerations During Assembly and Installation

During the assembly and installation of single girder overhead cranes, it’s crucial to prioritize safety. All personnel involved in the setup process should wear the appropriate Personal Protective Equipment (PPE), including hard hats, safety goggles, gloves, and shoes. Disconnect the power supply before working on any electrical components and ensure proper insulation to prevent electrical hazards.

Conclusion

The assembly and installation of single girder overhead cranes require careful planning, adherence to safety regulations, and attention to detail. By following the step-by-step process outlined in this article, you can ensure the successful assembly and installation of an overhead crane, leading to safe and efficient material handling operations within your facility. Regular maintenance and periodic inspections are essential for the ongoing reliability and safety of the crane.

To get more professional crane guidance, CONTACT US NOW! we are committed to providing a tailor-made solution that fits your specific needs. DGCRANE provides not only cranes but also a complete service, including offering free quotes, installation, and maintenance.

FAQs

- Q: Can overhead cranes be customized to fit specific requirements?

A: Yes, overhead cranes can be customized to fit the specific requirements of different industries and applications. Manufacturers offer a range of options and configurations to meet diverse needs. - Q: Are there any weight limitations for overhead cranes?

A: Yes, overhead cranes have weight limitations that depend on various factors such as the design, structural integrity, and load capacity of the crane. It is important to consider these limitations during planning and installation. - Q: How long does it take to assemble and install an overhead crane?

A: The time required for the assembly and installation of an overhead crane can vary depending on factors such as the size and complexity of the crane, the site conditions, and the availability of resources. It is best to consult with the manufacturer or an experienced contractor for a more accurate estimate. - Q: Are there any legal requirements for operating overhead cranes?

A: Yes, there are legal requirements and regulations for operating overhead cranes. These regulations may vary depending on the jurisdiction and industry. It is important to ensure compliance with these requirements to maintain a safe working environment.