Single Girder Overhead Crane Customization Made Easy: Choose the Perfect Solution for Small-height Factory

February 05, 2024

“My plant is low, how can I achieve a higher lifting height in a limited upper space?” Below will be an example to help you understand how to choose a customized single girder overhead traveling crane solution that better suits your needs in a low, limited-height space.

“My plant is low, how can I achieve a higher lifting height in a limited upper space?” Below will be an example to help you understand how to choose a customized single girder overhead traveling crane solution that better suits your needs in a low, limited-height space.

Factory Situation Analysis – Low and Limited Overhead Space

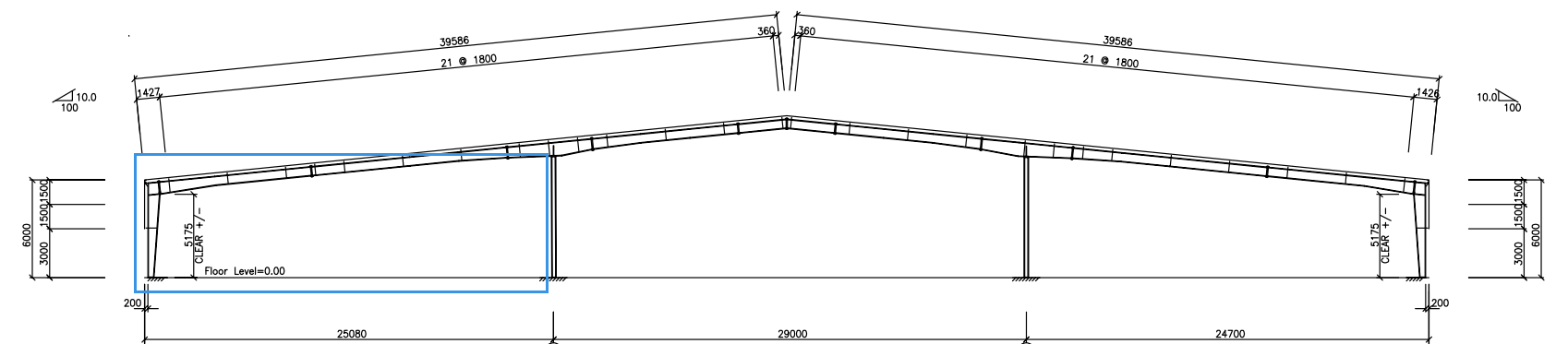

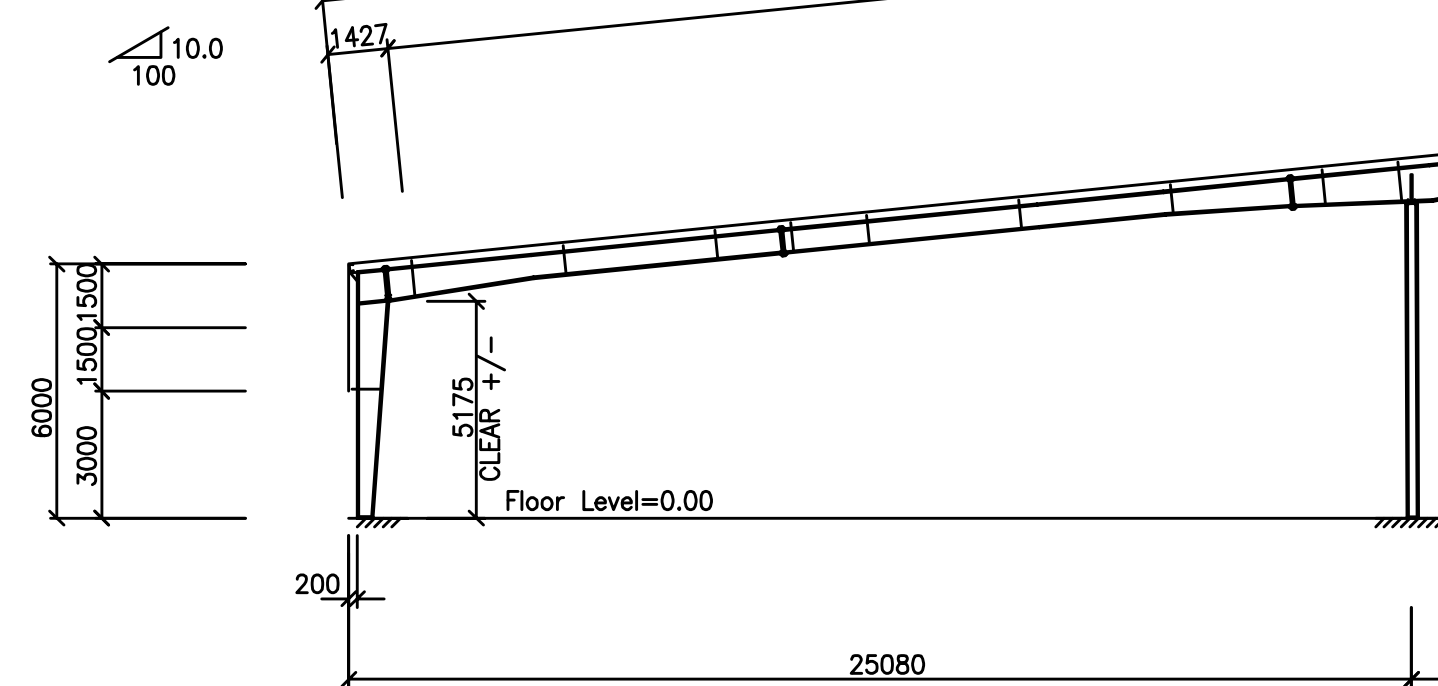

We received an inquiry from a client who wants to purchase 6 sets of 5-ton single girder overhead cranes for one of their spans in the workshop. However, the factory structure is relatively low, with the minimum height from the ground to the roof’s lowest part being only 5175mm. This falls into the category of low-height factory types:

Before purchasing a custom single girder overhead crane/single beam overhead crane, there are several key data points you need to be aware of:

Before purchasing a custom single girder overhead crane/single beam overhead crane, there are several key data points you need to be aware of:

- Lifting Capacity: This is the predetermined maximum weight the overhead crane is designed to lift. The rated lifting capacity is usually indicated on the nameplate of the hoist unit and the bridge structure.

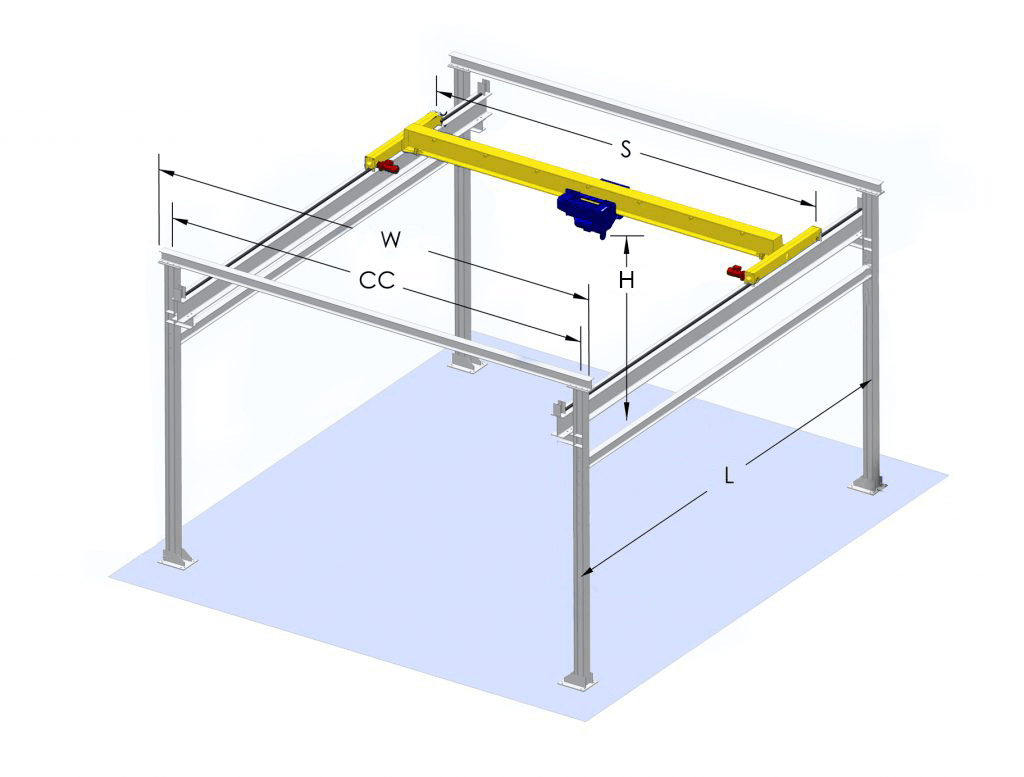

- Lifting Height (H): For a hook overhead crane, this typically refers to the height from the hook center to the ground. The distance from the top surface of the factory leg support to the lowest point of the roof determines which single girder overhead crane options are viable, thereby deciding the maximum lifting height.

- Span (S): The distance between the center positions of the two crane runway tracks determines the span. The span, in conjunction with the single girder overhead crane type selection, determines the left and right extreme positions for lifting.

- Crane Traveling Length (L): A single girder overhead crane generally covers a running distance of 50 to 60 meters.

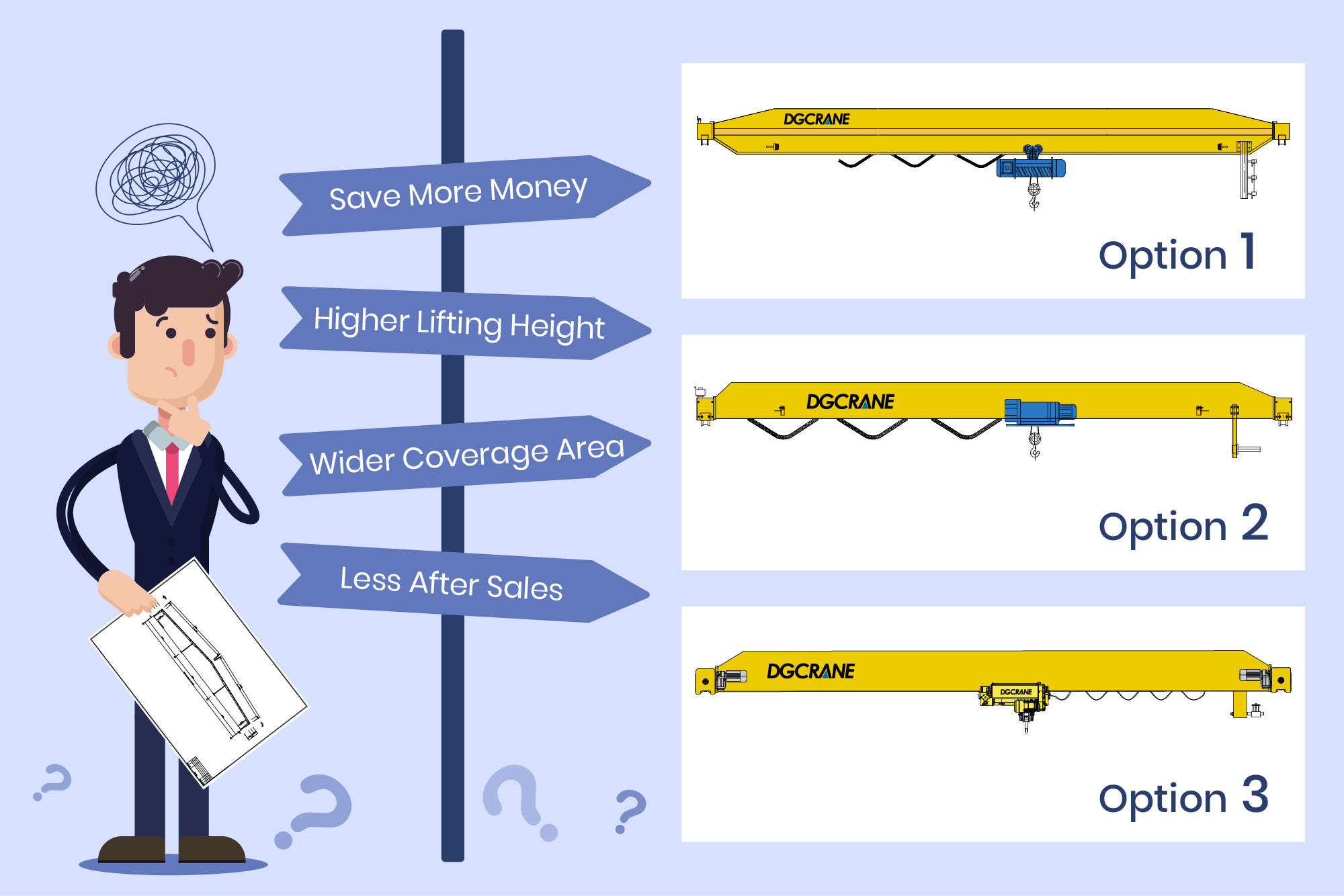

Solution Matching—Alternative Solutions for Adaptation

| Optional 5ton single girder overhead crane type |

Single girder electric overhead traveling cranes/Single girder EOT crane |

Low headroom single girder overhead crane |

|

| Corresponding type of 5ton single girder overhead crane drawing | LD type single girder overhead crane 5t S10.5m H3.135m A3 | LDC type single girder overhead crane 5t S10.5m H3.135m A3 | HD type single girder overhead crane 5t S10.5m H3.135m A3 |

Scheme Analysis – Comparison of Price, Lifting Height, Space Utilization, and After-Sales Maintenance

According to our previous experience, here are directional recommendations for customers when selecting a single-girder overhead crane solution:- If you want to choose the most cost-effective solution;

- In limited vertical space, customization for a higher lifting height is possible;

- If you want the maximum left and right extreme positions to achieve a larger coverage in the working area;

- To reduce post-maintenance, choose a more worry-free solution.

5ton Single Girder Overhead Crane Price Comparison

| Type | 5ton single girder EOT cranes | 5ton Low headroom single girder overhead cranes | 5ton FEM/DIN single girder overhead cranes |

|---|---|---|---|

| Description & Specification |

|

|

|

| Price (EXW) | $2700.00/set | $3100.00/set | $6000.00/set |

Lifting Height Comparison

The differences in lifting height for single-girder overhead cranes are influenced by several factors:- The connection method between the main girder and the end beam. In this case, the most suitable approach is the suspended connection, where the two ends of the main girder are connected to the flange in the middle of the end beam through high-strength locating bolts. However, for the 5-ton FEM/DIN single girder overhead crane, due to the smaller structure of the end beam, the end beam’s cross-sectional height is not sufficient to accommodate a significant number of connecting bolts and a seated structure connection must be adopted.

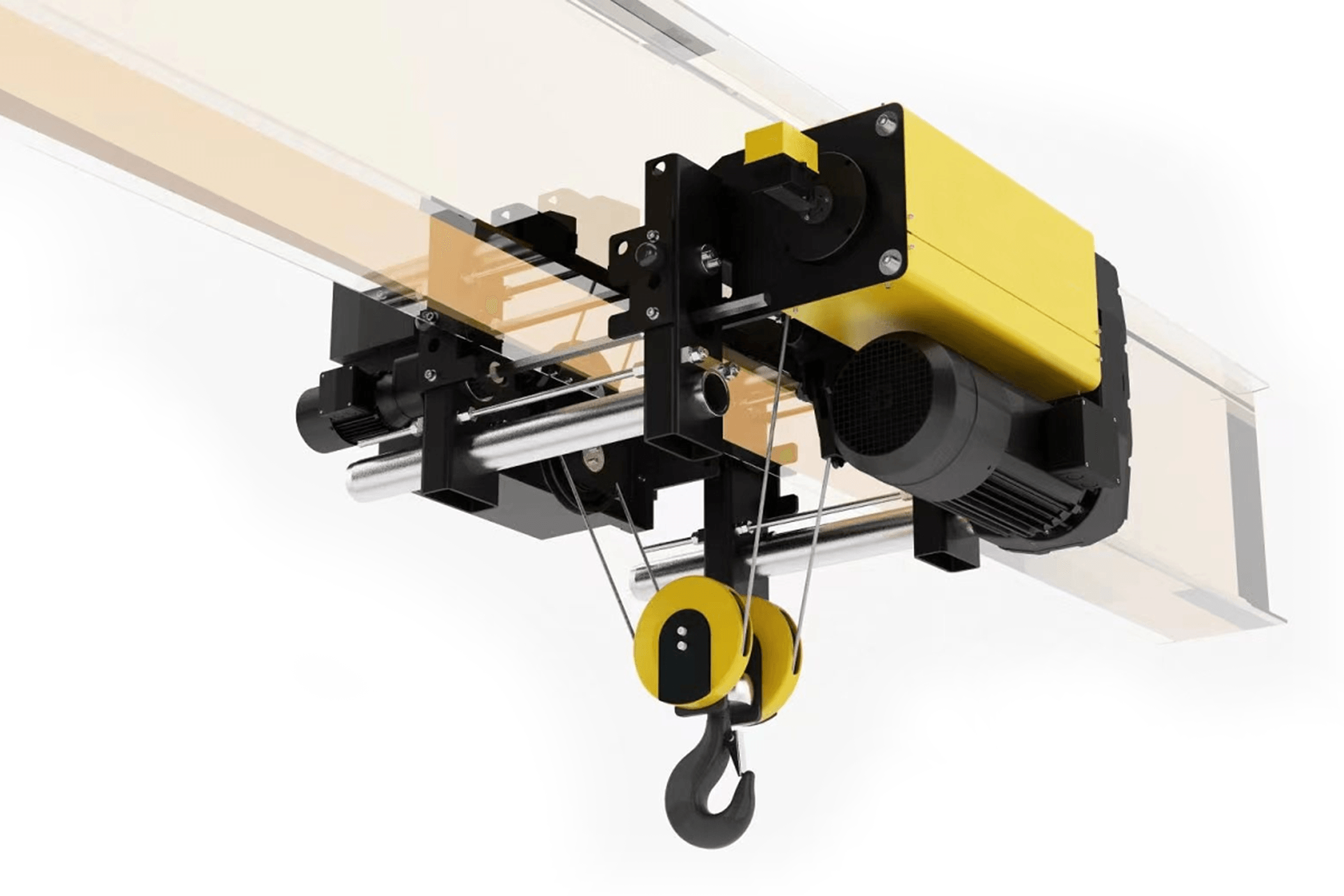

- The structural form of the electric hoist itself can determine the net lifting height of the electric hoist, i.e., the height from the hook center to the underside of the main girder’s bottom cover plate.

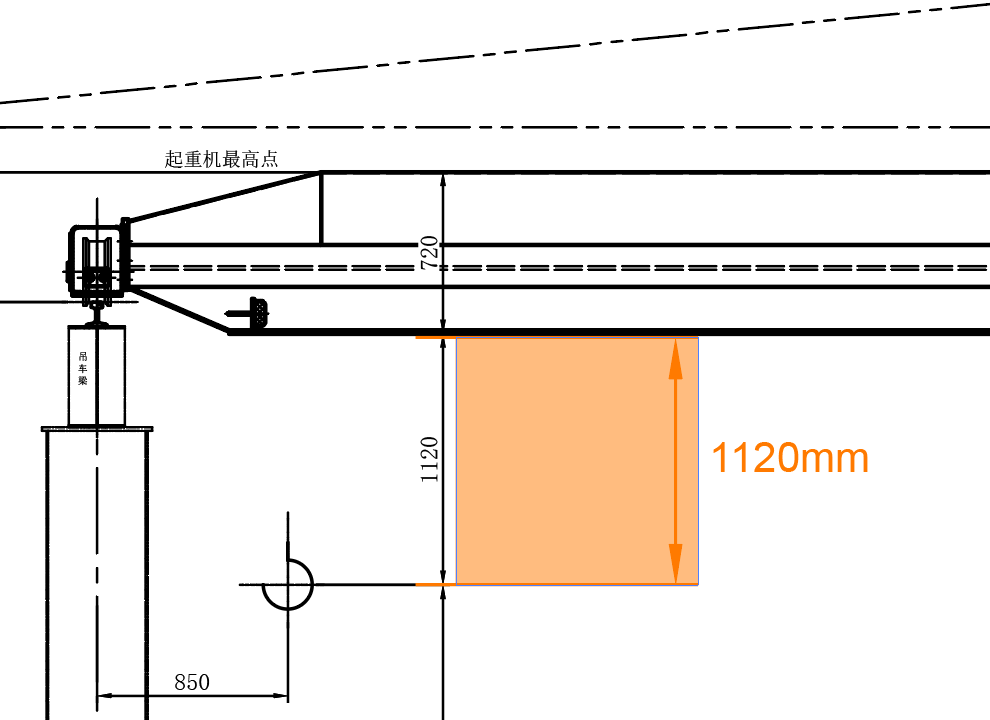

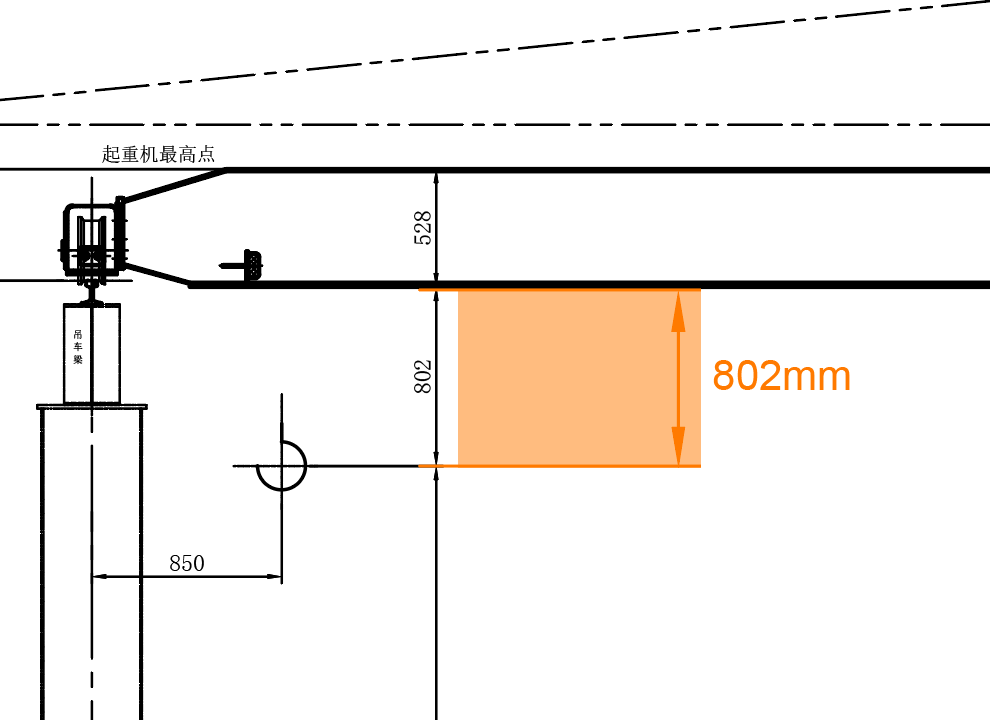

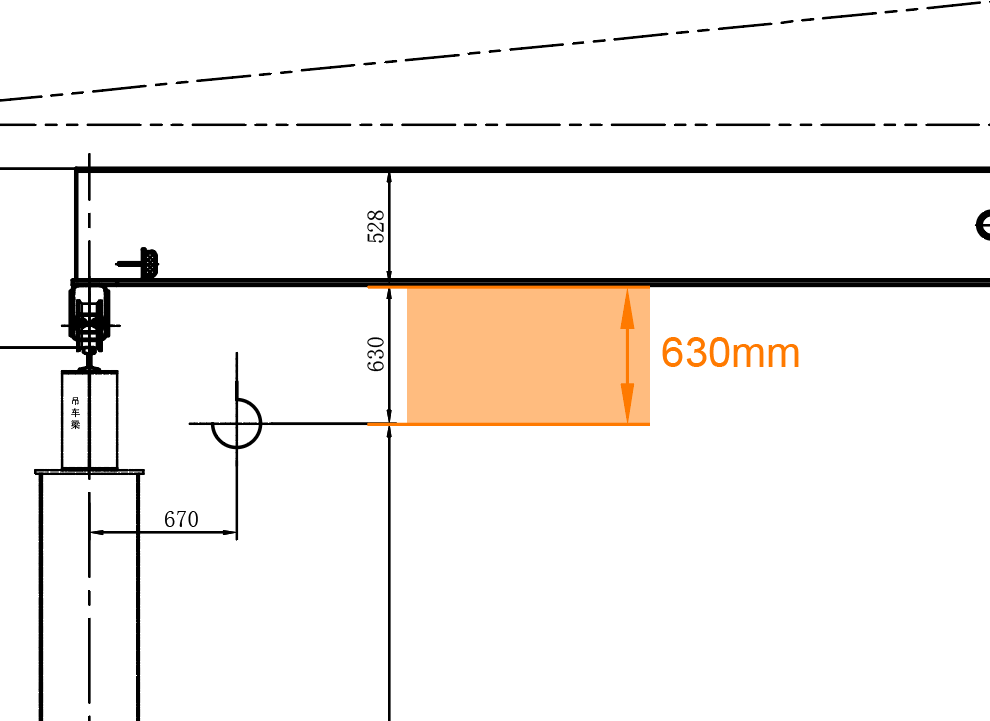

Comparison of Headroom Lifting Height for Electric Hoists

|

|

|

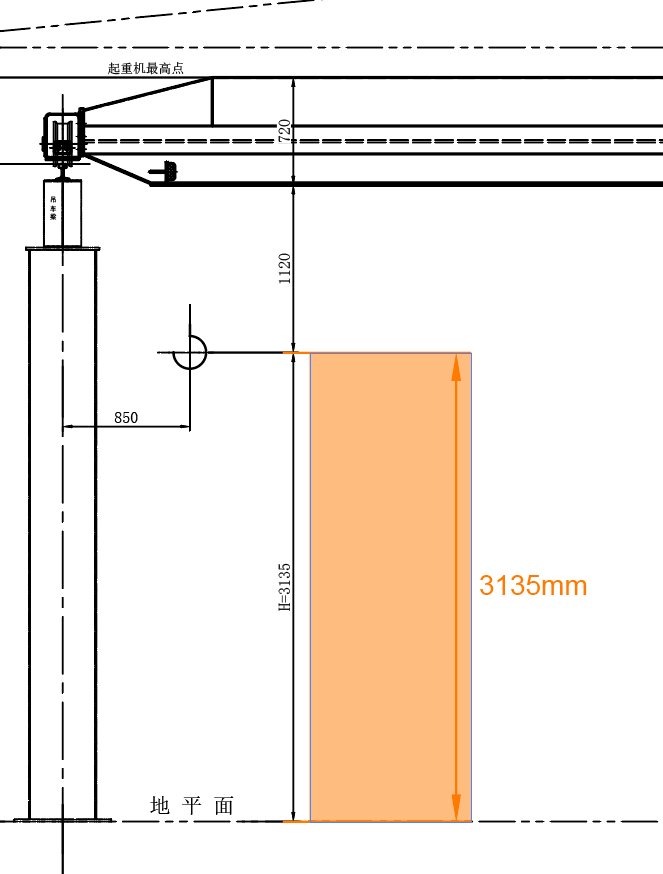

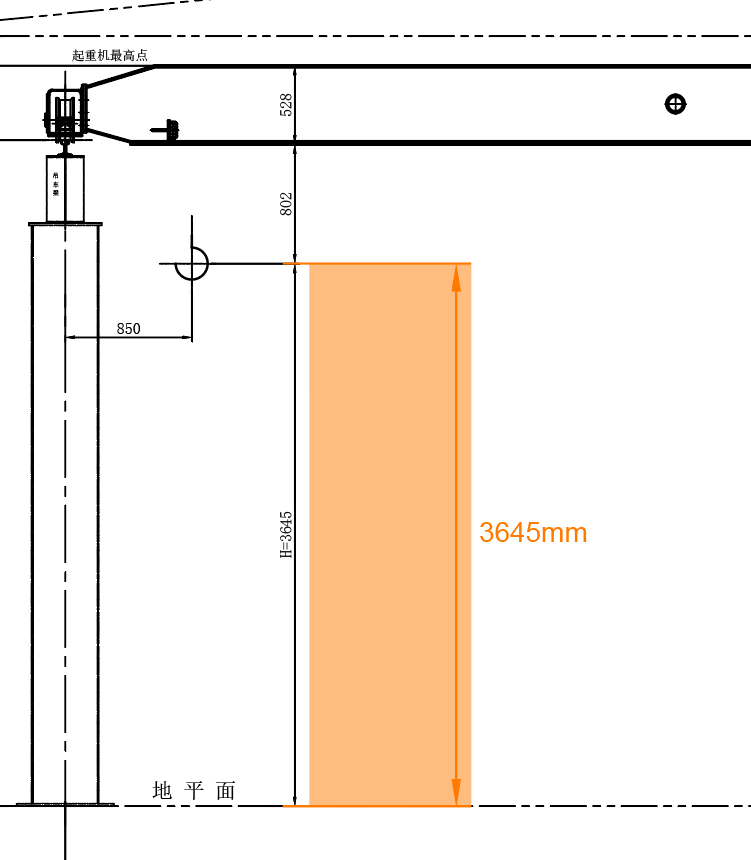

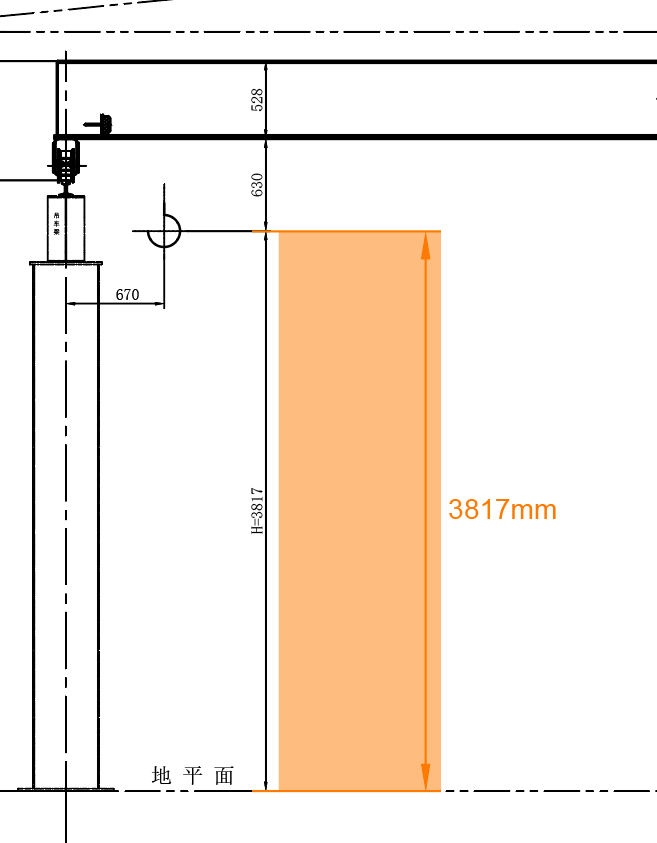

| CD type wire rope electric hoist: 1120mm | Low headroom type wire rope electric hoist: 802mm | Euro-type wire rope electric hoist: 630mm |

- The CD-type wire rope electric hoist has its trolley wheels located in the upper part of the hoist structure.

- In contrast, the low headroom-type wire rope electric hoist and Euro-type wire rope electric hoist have their trolley wheels positioned in the middle of the hoist structure.

|

|

| Operating position of the CD type wire rope electric hoist | Operating position of the Euro-type wire rope electric hoist |

Comparison of Maximum Lifting Heights

|

|

|

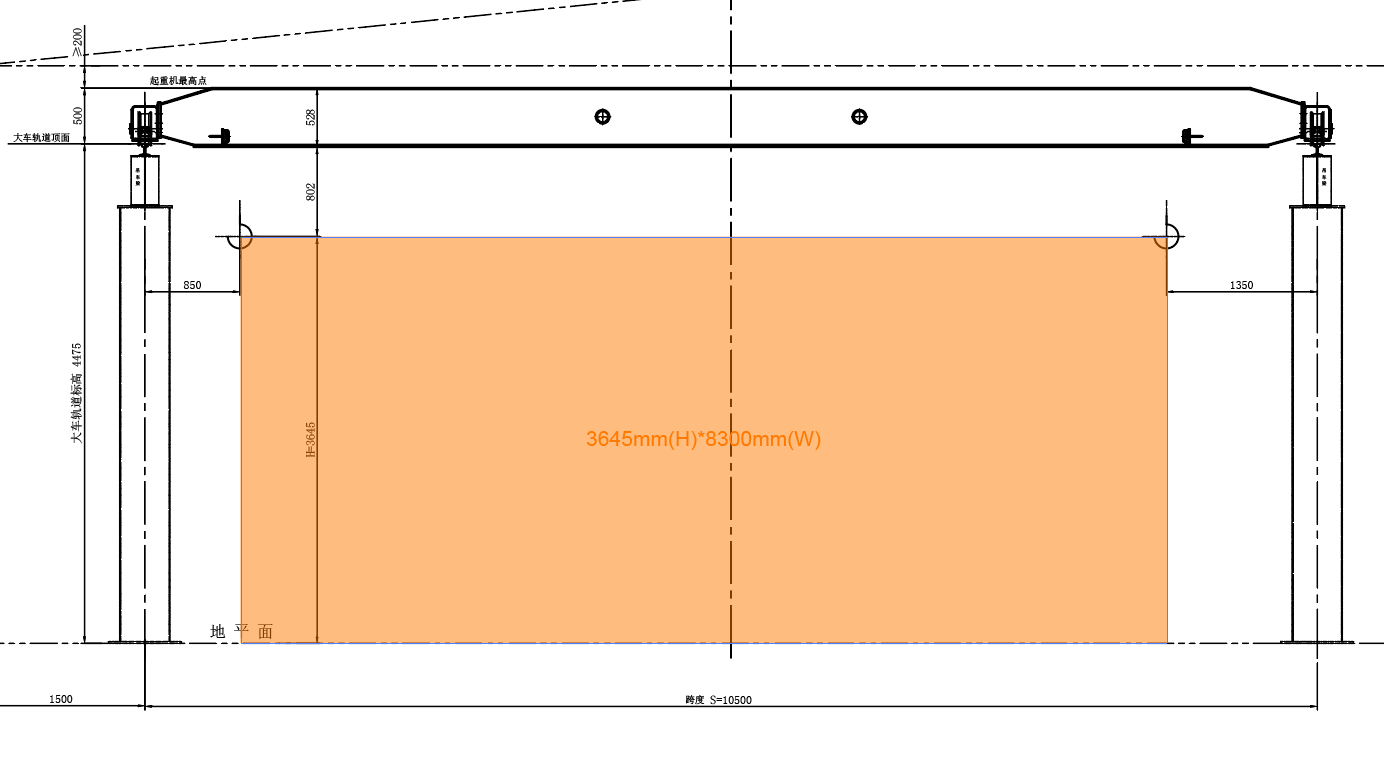

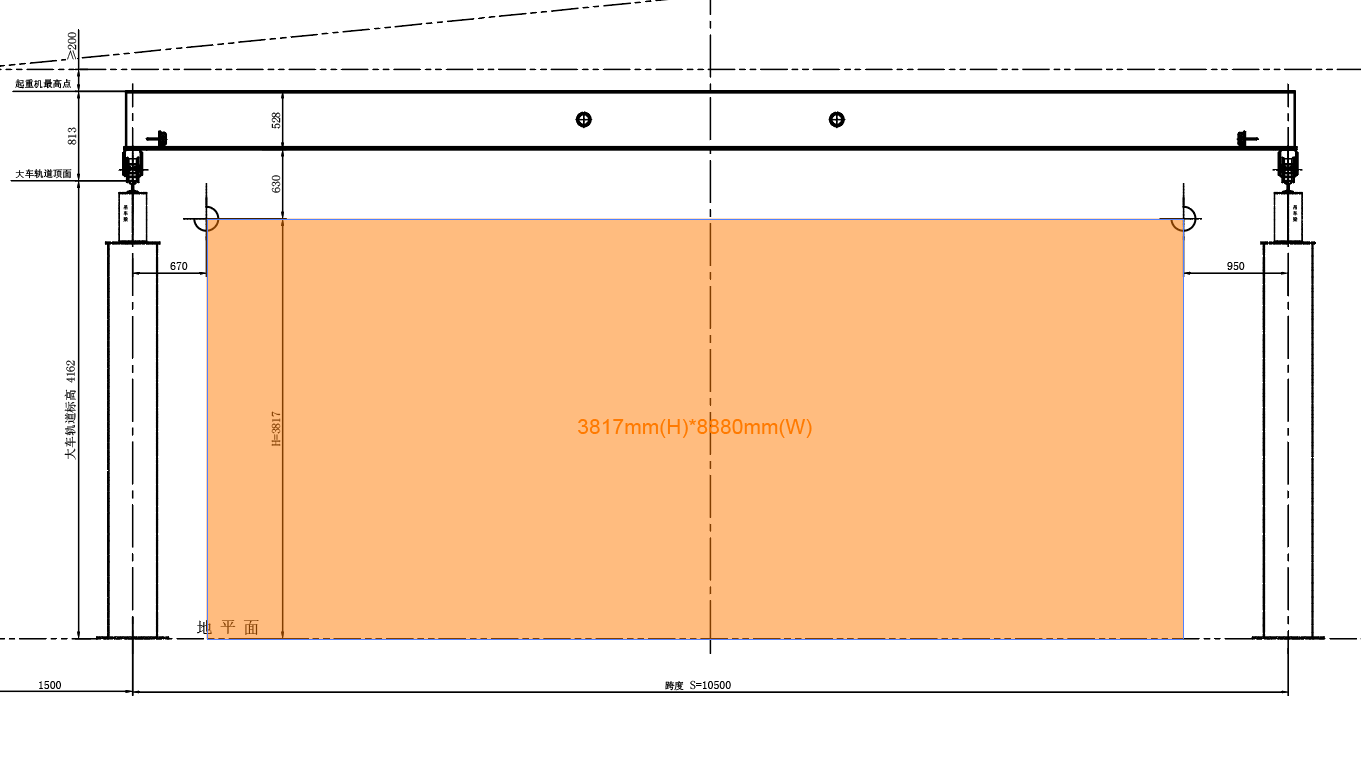

| The lifting height of the single girder EOT crane is 3135mm. | The lifting height of the low headroom single girder overhead crane is 3645mm. | The lifting height of the FEM/DIN single girder overhead crane is 3817mm. |

Comparison of Coverage for Left and Right Extreme Hoisting Positions

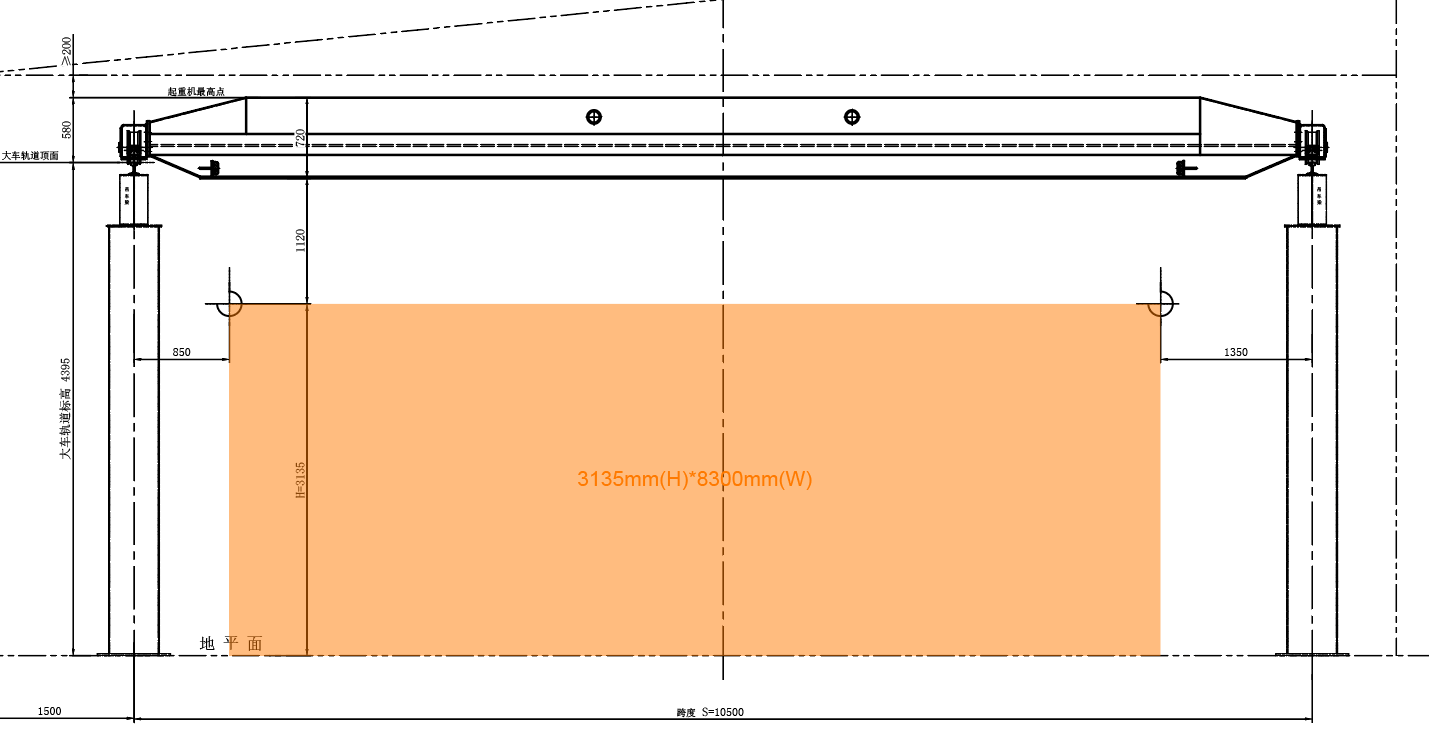

The left and right extreme positions determine the operational range limits that the overhead crane can cover. The left and right extreme positions that a 5-ton single girder EOT crane can cover have a width range of 8300mm.

The left and right extreme positions that a 5-ton single girder EOT crane can cover have a width range of 8300mm.

The low headroom single girder overhead crane can cover a width range of 8300mm for its left and right extreme positions.

The low headroom single girder overhead crane can cover a width range of 8300mm for its left and right extreme positions.

The FEM/DIN single girder overhead crane can cover a width range of 8880mm for its left and right extreme positions.

The left and right extreme positions for single-girder EOT cranes and low-headroom single-girder overhead cranes are the same. However, due to its compact design, the FEM/DIN single girder overhead crane can cover a wider working area. All three single girder overhead crane solutions are suitable for the layout of the customer’s machining lathes.

The FEM/DIN single girder overhead crane can cover a width range of 8880mm for its left and right extreme positions.

The left and right extreme positions for single-girder EOT cranes and low-headroom single-girder overhead cranes are the same. However, due to its compact design, the FEM/DIN single girder overhead crane can cover a wider working area. All three single girder overhead crane solutions are suitable for the layout of the customer’s machining lathes.

Comparison of Post-Sale Maintenance Requirements

- Brake Inspection: The FEM/DIN single girder overhead crane uses disc brakes, which are maintenance-free for a lifetime. In contrast, the brakes of single-girder EOT cranes and low-headroom single-girder overhead cranes need adjustment approximately every three months. Failure to perform maintenance adjustments can lead to serious consequences, such as excessive braking distance and hook slipping.

- Fault Code Display: Single girder EOT cranes and low headroom single girder overhead cranes can only be inspected for faults visually and with external testing equipment. The FEM/DIN single girder overhead crane has a natural advantage in fault troubleshooting. It can quickly identify the problematic point based on fault code numbers, facilitating swift resolution of issues.

- Motor Differences: The motors of single-girder EOT cranes and low-headroom single-girder overhead cranes use open transmission, resulting in high impact and noise. On the other hand, FEM/DIN single girder overhead crane typically adopts a three-in-one motor with closed transmission, offering a softer startup and longer lifespan.

- Black Box Function: During monthly inspections, the FEM/DIN single girder overhead crane can export data from the black box, providing insights into usage, stress distribution, and the remaining usage period. Single-girder EOT cranes and low-headroom single-girder overhead cranes rely on visual inspection to detect problems.

- Hoist Power Cable: Single girder EOT cranes and low headroom single girder overhead cranes use power cables, which are prone to tangling and disorder. In contrast, the FEM/DIN single girder overhead crane uses a C-shaped steel drag chain for more organized cable management.

In Conclusion

- From the price point of view, the price difference between a 5-ton single girder electric overhead traveling crane and a low headroom single girder overhead crane is not significant, while the price of a FEM/DIN single girder overhead crane is much higher.

- A comparison of lifting heights reveals a clear advantage for low headroom single girder overhead crane and FEM/DIN single girder overhead crane: a. Single girder electric overhead traveling cranes: 3135mm b. Low headroom single girder overhead crane: 3645mm c. FEM/DIN single girder overhead crane: 3817mm

- Concerning the maximum coverage of the working area caused by the left and right extreme positions, FEM/DIN single girder overhead crane has a significant advantage. However, considering the client’s actual usage scenario, the requirements for left and right extreme positions are not high.

- Based on our industry experience, FEM/DIN single girder overhead crane requires less post-sale maintenance.

5ton single girder overhead crane,Customized single girder overhead cranes,eot crane,low headroom height,overhead crane,Solutions for low-rise plants,Solutions for small-height factory