50 Ton Overhead Crane: Stable, Efficient, and Tailored to Your Needs

Table of Contents

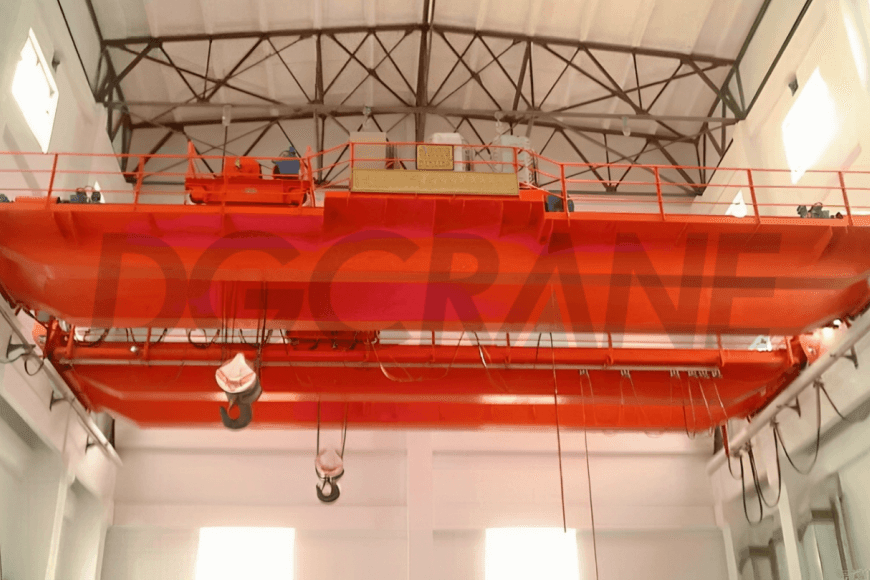

DGCRANE 50 ton overhead crane is an efficient and reliable material handling solution for a wide range of industrial applications. From steel coil handling to manufacturing and assembly support, it offers stable performance, flexible configurations, and precise control—making it an ideal choice for improving productivity and operational safety.

50 Ton Overhead Crane Price

Searching for a 50 ton overhead crane for sale? We offer high-performance lifting solutions tailored to your specific needs. Because our cranes are fully customizable — including span, lifting height, duty cycle, and control systems — the 50 ton overhead crane price can vary depending on your project requirements. Rather than a fixed 50 ton overhead crane cost, we provide tailored pricing based on your application, site conditions, and technical specifications. Reach out today to get a personalized quote from our experienced team.

| Products | Capacity(t) | Span(m) | Lifting height(m) | Working duty | Price($) |

|---|---|---|---|---|---|

| 50 Ton QD-type Double Girder Overhead Crane With Winch Trolley | 50t/10t | 10.5-31.5 | 12/14 | A5,A6 | $49500-$72000 |

| 50 Ton FEM Double Girder Overhead Crane | 50t/10t | 13.5-31.5 | 12/14 | A5 | Customized Pricing |

| 50 Ton Ladle Handling Cranes for Foundry | 50t/10t | 13.5-31.5 | 12/14 | A7 | Customized Pricing |

| 50 Ton Electromagnetic Overhead Cranes with Lifting Magnet | 50t/10t | 10.5-31.5 | 12/14 | A6 | Customized Pricing |

| 50 Ton Insulated Overhead Cranes | 50t/10t | 10.5-31.5 | 12/14 | A6 | Customized Pricing |

| 50 Ton Explosion Proof Double Girder Overhead Crane | 50t/10t | 10.5-31.5 | 12/14 | A4 | Customized Pricing |

50 Ton Overhead Crane Application

50 ton overhead cranes are widely used in industries such as steel production, aerospace, and non-ferrous metal processing. They are suitable for precise and efficient material handling in environments that require stable and reliable lifting operations.

Aerospace Industry

The FEM double girder overhead crane plays a crucial role in the transportation and lifting of rockets, accurately handling tasks such as in-plant transfer, repositioning, turning, inspection, testing, and fuel filling. Our independently developed electrical anti-sway automatic positioning micro-movement control system ensures high-precision hoisting and transportation for rockets.

Steel Manufacturing Industry

Ladle handling crane is a key piece of equipment in the steelmaking process of a steel plant. It is primarily used to pour molten iron into the converter in the converter bay, transfer the ladle to the refining furnace in the refining bay, and lift the ladle onto the rotating platform of the continuous casting machine in the casting bay.

This crane operates under harsh environmental conditions, including high temperatures, heavy dust, and harmful gases. Therefore, it must meet extremely high standards in design, manufacturing, inspection, operation, and maintenance.

Non-Ferrous Metal Smelting Industry

Insulated overhead cranes are designed for demanding environments where non-ferrous metal smelting is required. Our cranes offer superior safety and reliability, ensuring efficient operation in industries such as aluminum, magnesium, lead, and zinc processing.

Automotive Industry

In the automotive industry, 50 ton overhead cranes play a critical role in handling steel coils, transferring heavy stamping dies, and assembling large vehicle components. Their precision, reliability, and high load capacity help streamline production and ensure workplace safety.

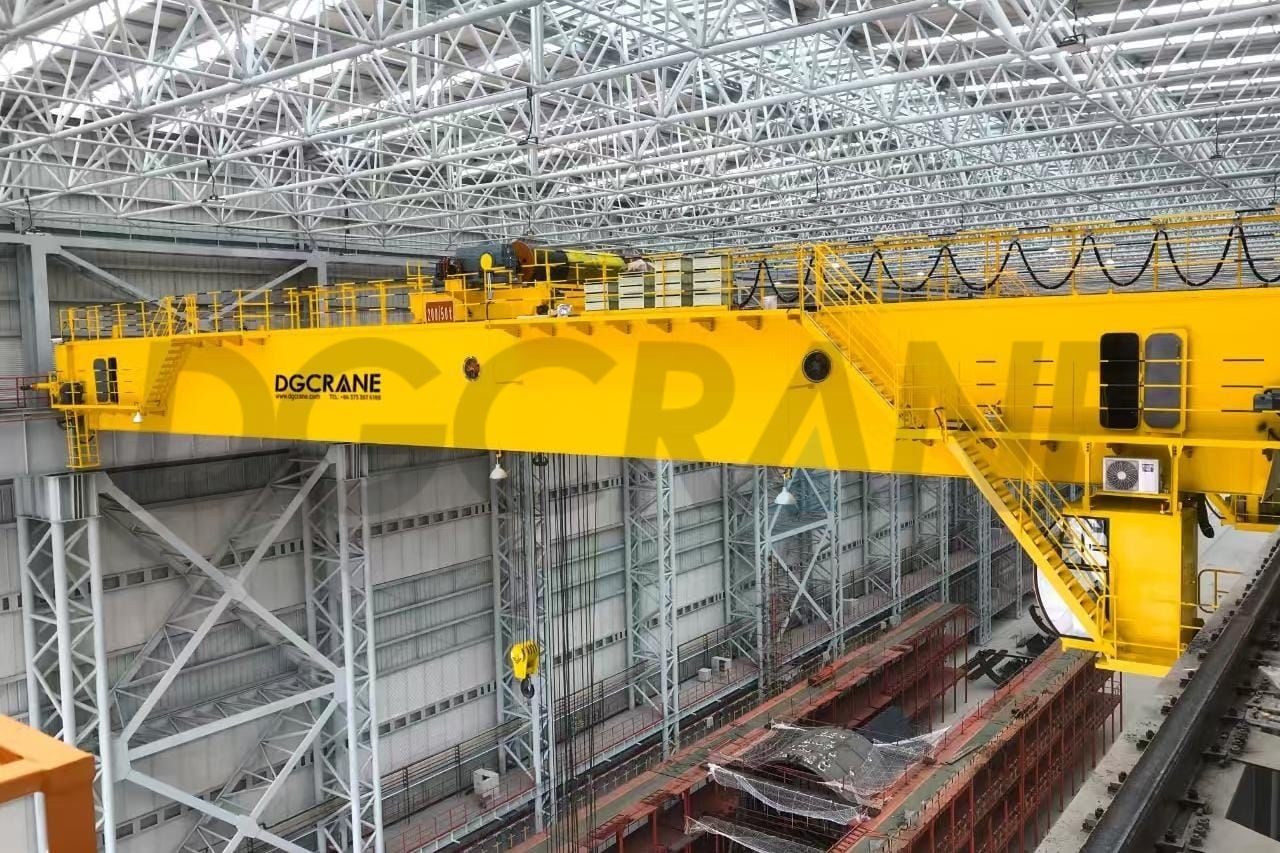

50 Ton Overhead Crane Cases

Our 50 ton overhead crane solutions have been successfully delivered to clients worldwide. Each case highlights our ability to provide reliable, tailored lifting equipment that adapts to unique project needs and site conditions.

2 sets of 50/10 ton Double Girder Overhead Cranes Delivered to Nigeria

We received an inquiry in August 2011, referred by a contact from a company called Mayflower. We had been in touch with this contact since March 2011 regarding their need for double girder overhead cranes for a new factory in Brazil. However, the project was delayed by about three months, and they mentioned plans to visit our factory once the timeline resumed. Additionally, they informed us they would be coming to China along with a business partner from Britain, who was at that time working on a crane project in Nigeria.

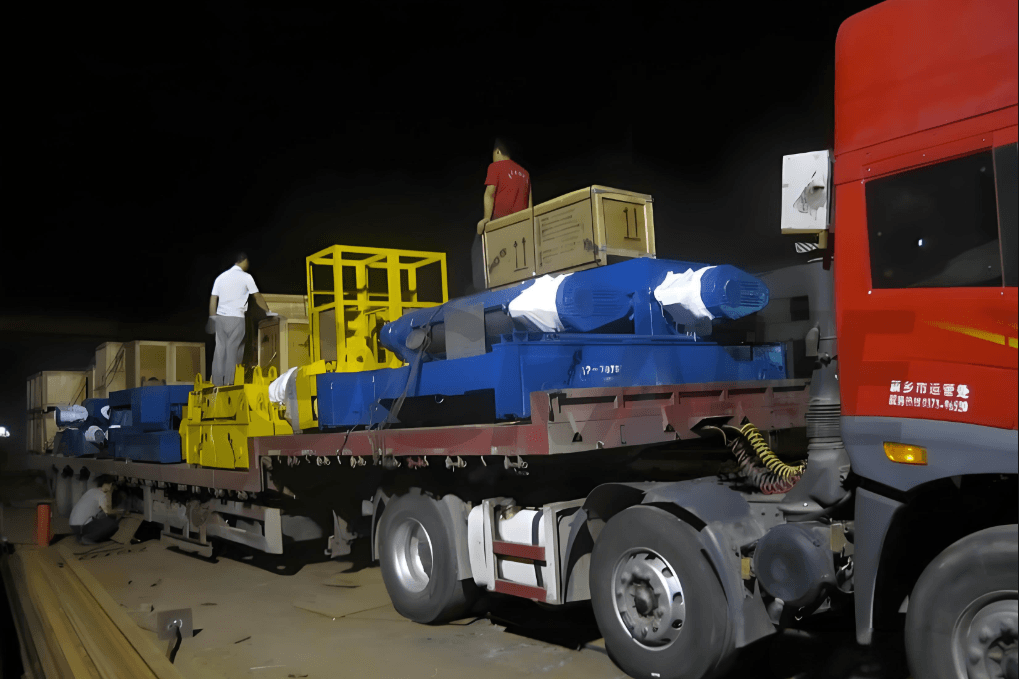

The Nigeria double girder overhead cranes? Production took 3 months, and after all the production was finished, we did crane commissioning as per our contract, and we also invited the customer to our factory for inspection.

LH 50 Ton Double Girder Overhead Crane Exported to Iraq

After about 4 months of communication, our client placed the order with us. The crane is used to lift plastic products. considering that the cranes don’t work frequently, we suggest work duty A3 (double girder overhead crane with chain hoist trolley). The customer is very satisfied with our design.

Detailed specifications:

- Type: LH Double Girder Overhead Crane With Chain Hoist Trolley

- Capacity: 50ton

- Span length: 13m

- Lifting height: 6m

- Work duty: A3

- Control mode: Pendant control + Remote control

- Power source: 380V/50Hz/3Ph

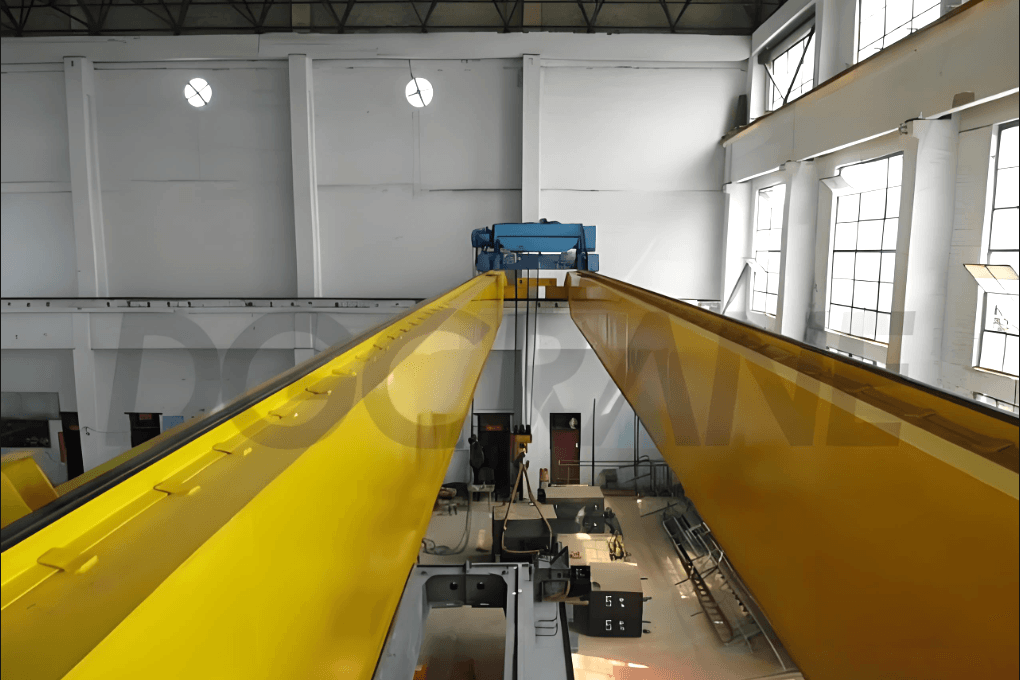

2 Sets of QE Double Girder Overhead Cranes Exported to Tanzania

The first inquiry was received on Apr 20th, The client is purchasing 2 sets of double girder overhead cranes for a new hydro power station project located in the Southern highland of Tanzania. Each crane has 2 separate trolleys, the second trolley will be used for turning some components during a re-assembly process.

Detailed specifications:

- Crane model: QE

- Capacity: 40+10ton

- Span length: 13m

- Lifting height: 12m

- Work duty: A5

- Power source: 400V/50Hz/3Ph

- Control mode: Pendant + remote control

Based on the client’s requirement, we consider designing the crane to winch trolley type, the lifting mechanism is a split design, cross traveling and crane traveling mechanism adopts a three-in-one design. The advantage of this kind of design is:

- Lifting speed has more than two speeds, which are controlled by a variable frequency inverter; the speed can be changed smoothly without impact. The motor/reducer/brake has a split design and is easy to repair and replace parts.

- The rope drum has independent support and can be replaced independently without lifting the whole trolley. There is an independent maintenance platform.

- With an independent brake, you can directly observe the wear of the brake pads, with an automatic compensation function, manual release function, friction pad replacement alarm function (optional), easy adjustment, and convenience for maintenance.

- Heavy-duty design with lifting capacity 5-500t Suitable for hoisting large equipment such as steel mills, hydropower stations, aerospace, nuclear power plants, etc.

44/15/15 Ton Double Girder Overhead Crane Delivered to South Africa

This double girder overhead crane was customized to meet the customer’s special requirements for the hook's left and right travel limits. Our engineers did everything possible to accommodate these non-standard needs, resulting in a highly tailored design. Since the required voltage of 525V is quite uncommon, production took nearly four months. The crane was loaded for shipment at Tianjin Port.

Detailed specifications:

- QDY model double girder casting overhead crane

- Country: South Africa

- Capacity: 44/15/15ton

- Span length: 18m

- Lifting height: 17m

- Control mode: Remote control

- Power source: 525V/50Hz/3PH

- Work duty: ISO A8/M8

40 Ton Double Girder Overhead Crane For Sale to Peru

This is a new customer from Peru, the 40 ton double girder overhead crane is used inside for installation and repair of equipment, it is used few times a month, so we suggest the LH model with work duty A3, and it is installed at the altitude over 3000m, we have fully considered this factor when design 40 ton overhead crane drawing. We have designed and delivered many 40 ton overhead cranes for special environments; this design was accepted by customers soon.

Detailed specifications:

- Capacity: 40ton

- Span length: 7m

- Lifting height: 9m

- Work duty: A3

- Power source: 380V/60Hz/3Ph

Why Choose DGCRANE’s Crane?

DGCRANE specializes in customized overhead crane solutions tailored to your industry needs. With years of experience in heavy lifting equipment, we offer:

- Tailor-Made Designs – Every crane is engineered to match your specific working conditions and load requirements.

- Reliable Quality – Built with high-grade materials and advanced manufacturing processes to ensure durability and safety.

- Competitive Pricing – Factory-direct supply with optimized cost control without compromising on performance.

- Global Service – Fast response, multilingual support, and installation guidance for customers worldwide.

- Proven Track Record – Successfully serving clients in steel, aerospace, automotive, and energy sectors across over 100 countries.

50 Ton Overhead Crane FAQ

What is a 50 ton overhead crane?

A 50 ton overhead crane is an industrial lifting device designed to lift and move heavy loads of up to 50 tons in places such as factories, warehouses, freight yards, and logistics parks.

What are the main application areas of a 50 ton overhead crane?

The main application areas include the automotive manufacturing industry, non-ferrous metal smelting industry, steel manufacturing industry, and aerospace industry, where it is used to handle raw materials, equipment, and finished products.

What is the initial purchase cost of a 50 ton overhead crane?

The cost of a 50 ton overhead crane depends on various factors, including the crane type, span, lifting height, duty classification, control method, and whether special features or customization are required. The higher the level of customization and the more complex the supporting systems, the higher the price.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!