4 Tips For How To Ensure Crane’s Quality When You Buy it Overseas: Most Comprehensive Guide

What should a high-quality crane look like?

A crane is a mechanical device used for lifting and moving heavy objects, widely used in industries such as construction, logistics, and manufacturing. The quality of a crane directly affects its performance and safety, so it is important to determine its quality.

- Reasonable design:

The mechanical structure of the crane has a significant impact on its quality and safety. - Material quality:

You can check the quality assurance certificate of the steel and profile steel, or judge the rigidity of the crane’s main beam by observing the deflection during a static load test. - High-quality components:

The transmission part of the crane includes electric hoists, brakes, reducers, etc. Generally, high-quality transmission parts produce less noise. - High-quality appearance:

The quality of a crane can be initially judged by observing its appearance. - Smooth operation:

The crane can achieve a soft start effect by controlling the operating speed through frequency conversion. - Safety performance:

The safety performance of the crane is also very important and should have complete safety protection measures and operating procedures to avoid accidents4 methods to ensure the quality of a crane

4 methods to ensure the quality of a crane

When we decide to purchase a crane from overseas, the biggest concern is buying a low-quality product. This not only makes maintenance difficult and seriously affects the daily work of the factory, but also poses a safety hazard. Therefore, it is important to monitor the quality of the crane. Through the above explanation, I believe that everyone has a comprehensive understanding of how to judge the quality of a crane. Next, let’s talk about how to ensure that you buy a high-quality crane from four aspects, which I believe will be helpful for your purchase.

1. Information that can be collected online

- Official website:

Learn about the seller’s establishment time and transaction records from the official website. Generally, the longer the manufacturer has been established, the more reliable the quality of its products. Because their products have passed rigorous industry inspections, if their product quality does not meet industry requirements, the company is unlikely to have developed to this day. - Catalog:

Ask the salesperson to send the product catalog to see the relevant details of the product. - Relevant certificates:

Check whether the manufacturer has relevant quality certification certificates. - After-sales warranty:

Learn about related after-sales warranty services from the salesperson. - Customer reviews:

Check the manufacturer’s official website or past order information to see if you can find the customer company of the manufacturer and learn about the quality of the product. - Design drawings:

Ask the salesperson to send the product design drawings to understand the strength of the manufacturer’s design team and check the rationality of the product design.

2. Visit the factory

When is it more cost-effective to visit the factory?

- Large orders or long-term cooperation

- Third-party services or friends who visit the factory on behalf of customers

What to look for when visiting the factory?

- On-site inspections can evaluate the actual situation of the seller’s factory, production environment, manufacturer scale, and related production qualifications.

- You can observe the seller’s personnel and communicate with the seller face-to-face to understand their professionalism.

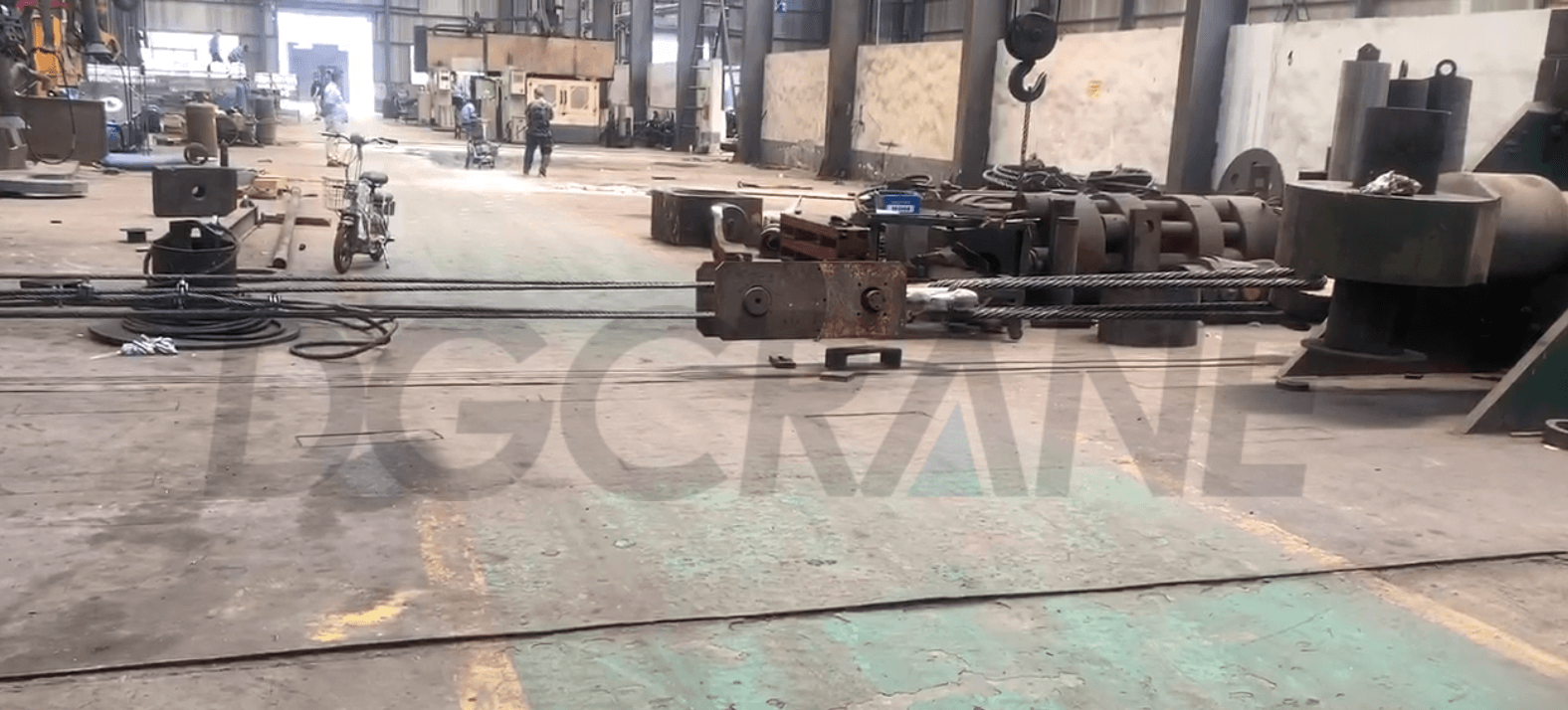

- The main focus of visiting the factory is to look at the product, including the material, production equipment, manufacturing process, processing process, how the assembly line production is carried out, how each step pays attention to details, and how to ensure quality. For example, how to deal with welding points to ensure firmness, which links are integrated design, and which are detachable design, etc. This way, you can have a clear understanding of the product quality.

- Look at the functional performance of the product, such as how stable the equipment runs, how many people are needed to operate it, and how to deal with faults during operation. Seeing the equipment start up and run is enough to explain the problem!

Real case

Recently, a Thai customer visited our factory. The customer had a project for a 30/5 ton double-beam gantry crane. We accompanied the customer to visit the production process, finished product area, and testing area of the gantry crane that the customer wanted to see. He was very satisfied with this visit and communicated with our company’s purchasing manager to sign the contract on the same day.

Our company’s various cranes can be visited freely, including the production line, finished product area, testing area, delivery area, etc. We support various authoritative organizations to conduct inspections and provide reasonable prices and the best quality!

Feel free to contact us. 🤝 🤝 🤝

https://www.dgcrane.com/contact-us/

DGCRANE will provide the best products and best service to you.

3. Relevant inspections

Factory inspection

When is a factory inspection needed?

- Well-known brands

- Long-term cooperation

Inspection purposes

- To check whether the factory has the ability to complete orders in terms of quality and quantity. Only with a practical and effective quality management system in operation can the factory ensure that the products produced are qualified and can be delivered on time. At the same time, the factory’s production capacity, equipment, and employee productivity should also be considered comprehensively.

- To reduce unnecessary troubles. Foreign customers are far away from China. If there are problems with the contracted factory’s products or management, it will be difficult to solve. Therefore, optimizing supply chain management and implementing factory inspections before purchasing can comprehensively evaluate the contracted factory to ensure that there are no major or serious problems with the supplier, avoid costly supply chain interruption problems, and ensure the supplier’s ability and reliability before including them in the supply chain. Only then can orders be placed and long-term cooperation established.

- For their own business image and corporate reputation. For example, people cannot accept a company like Walmart, the top of the Fortune 500, whose suppliers are all sweatshops, and whose profits are based on the oppression and exploitation of workers. Therefore, Walmart needs to strictly select its suppliers, fully understand the supplier’s procurement and operation policies, and ensure that they are consistent with your company’s brand image.

What is a factory inspection?

A factory inspection, also known as a factory audit or factory visit, is an inspection of the factory by the customer or a neutral third-party organization. It is generally divided into human rights inspections (social responsibility inspections), quality inspections (quality and technical inspections), anti-terrorism inspections (supply chain security inspections), etc. Of course, there are also some integrated inspections, such as human rights and anti-terrorism inspections, human rights, anti-terrorism, and quality inspections, etc.

- Human rights inspection

Officially known as social responsibility audit, it requires suppliers to fulfill defined obligations in labor standards and worker living conditions. It is divided into corporate social responsibility standard certification and customer standard audit. - Quality inspection

Also known as quality inspection or production capacity evaluation, it indicates that the factory has the ability to continuously produce qualified products that meet customer requirements and applicable regulatory requirements. Its standards are often not “universal standards.” This type of factory inspection is not very common, and the audit difficulty is also lower than that of social responsibility inspections. - Anti-terrorism inspection

It is not very popular and appeared after the 9/11 incident in the United States. It is generally required by American customers and generally has two types: C-TPAT and GSV. The main purpose of anti-terrorism inspections is to ensure the transportation and use safety of exported goods through the factory’s own set of security control procedures.

Load testing

The supplier is required to perform load testing on the crane before delivery to ensure that it meets the specified specifications and safety standards. The load test of the crane includes empty load, static load, and dynamic load tests.

Third-party inspection

Third-party inspection of product performance To ensure the quality of the product, you can also find a third-party organization to inspect the performance of the product. Some large factories can support third-party inspections.

Real case

Recently, we had a Swedish customer who was engaged in cargo handling and was a pioneer in dock automation and energy-saving container handling. They have very high requirements for product quality and need customized non-standard hooks. The supplier needs to have sufficient strength to undertake the material, design, and safety testing aspects. We are very happy that after we carefully introduced our experience and capabilities and showed our design drawings to the customer, we finally gained the customer’s trust and recognition.

In addition, according to the customer’s requirements in this order, this batch of products underwent third-party inspections. This hook underwent a 50t tensile test in the most authoritative institution in China. This test can verify the process quality of the product and ensure the safety of subsequent use.

Below are pictures of the product and tensile test.

Feel free to contact us. 🤝 🤝 🤝

https://www.dgcrane.com/contact-us/

DGCRANE will provide the best products and best service to you.

4. Crane commissioning and acceptance

Whether the data is complete (including but not limited to):

- Outgoing inspection report

- Product certificate of conformity

- Certificate of conformity for accessories

- Declaration of conformity

- Product quality certificate

- Crane product certificate of conformity

- Details of various technical documents

- Qualifications

- Packing list

- Random drawings

- Nameplate (already attached to the crane)

- Installation, maintenance, and operation manual

- Product quality feedback and suggestions

- Crane mechanical installation and construction plan

- Notice of installation, renovation, and maintenance of special equipment

- Self-inspection records for crane installation (renovation, major repairs)

Physical acceptance (including but not limited to):

- Compare the packing list to confirm the quantity of equipment accessories and random attachments.

- Installation size and position requirements: based on the agreed equipment installation drawing.

- Check whether the equipment has obvious deformation, cracks, defects, etc. Inspection method: visual inspection

- Check the appearance paint of all components to confirm that there is no leakage or obvious color difference. Inspection method: visual inspection

- Check the welds of all components to confirm that there is no open welding, the welds are flat and smooth, and there are no missing welds, porosity, slag inclusion, undercut, false welding, etc. Inspection method: visual inspection, touch with gloved hands

- Functional testing, such as starting, stopping, walking, lifting, rotating, etc., requires checking whether the equipment’s control system, transmission system, hydraulic system, electrical system, etc. are operating normally. At the same time, it is also necessary to check whether the equipment’s response speed, load-bearing capacity, and other parameters meet the standard requirements.

Conclusion: Ensuring the quality of cranes mainly involves four aspects: information that can be found online, factory visits, various related inspections, and final acceptance.

What situations have you encountered when purchasing cranes overseas? I would love to hear everyone’s stories.

Feel free to contact us. 🤝 🤝 🤝

https://www.dgcrane.com/contact-us/

DGCRANE will provide the best products and best service to you.