20 Ton Overhead Crane: Powerful, Reliable, Customized for Your Needs

Table of Contents

Looking for a lifting solution that combines strength, precision, and efficiency? DGCRANE's 20 Ton Overhead Crane is engineered to handle tasks across various industries with ease. Backed by advanced technology, premium components, and flexible customization options, it's the ideal choice to boost your productivity and ensure safe, seamless operations.

20 Ton Single Girder Overhead Crane

20 Ton Double Girder Overhead Crane

20 Ton Overhead Crane Price

When selecting a 20 ton bridge crane, the price can vary significantly depending on the model, configuration, features, and customization options. More importantly, the right crane depends on your specific application—whether for manufacturing, steel processing, warehouses, shipyards, or heavy construction sites, different environments require different crane types.

Whether you’re searching for a 20 ton overhead crane for sale or looking for detailed 20 ton EOT crane price, we provide comprehensive options to fit various budgets and requirements. Explore our price list below to see available models and price ranges, or contact us for a customized quote tailored to your needs.

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 20 Ton Single Girder Overhead Crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $7,100-18,300 |

| 20 Ton Low Headroom Single Girder Overhead Crane | 7.5-31.5 | 6-30 | 220V-660V, 50-60Hz, 3ph AC | $7,500-19,300 |

| 20 Ton LH-type Double Girder Overhead Crane With Hoist Trolley | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | $25500-45900 |

| 20 Ton QD-type Double Girder Overhead Crane With Winch Trolley | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | $25500-45900 |

| 20 Ton FEM Double Girder Overhead Crane | 10.5-31.5 | 16/18 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Grab Bucket Overhead Crane | 16.5-31.5 | 26 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Insulated Overhead Cranes | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Electromagnetic Overhead Cranes with Lifting Magnet | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Electromagnetic Overhead Cranes with Magnet Beam | 22.5-34.5 | 15-16 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Explosion Proof Single Girder Overhead Crane | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

| 20 Ton Explosion Proof Double Girder Overhead Crane | 10.5-31.5 | 12/14 | 220V-660V, 50-60Hz, 3ph AC | Customized Pricing |

Note: Updated on January 2024, Industrial Machinery products are subject to market changes and are for reference only.

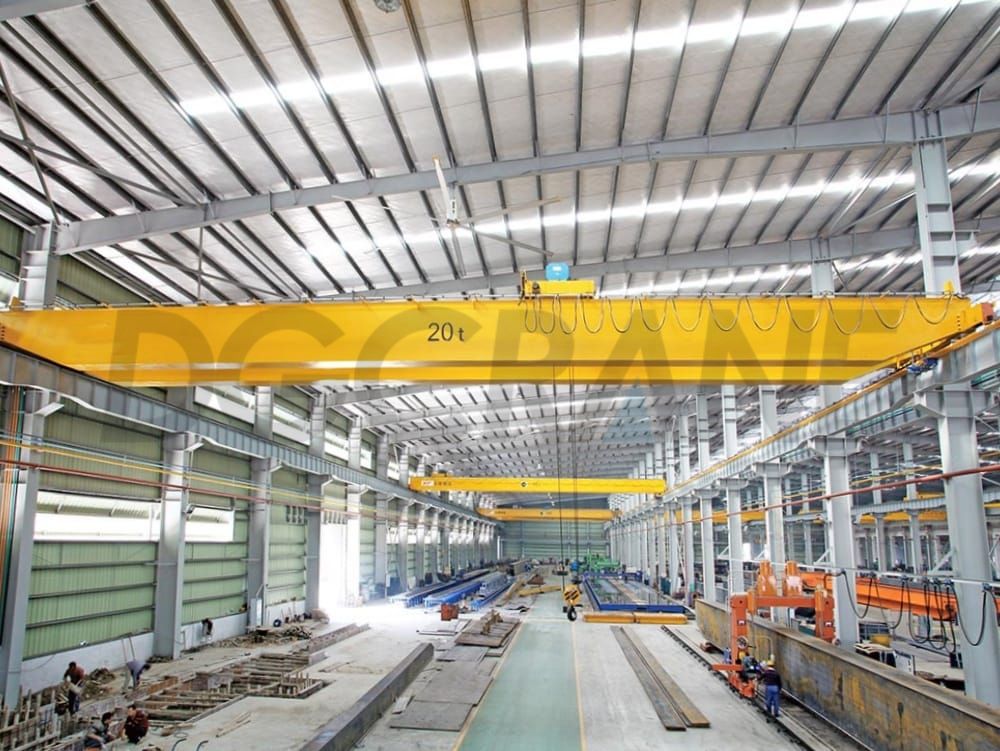

20 Ton Single Girder Electric Overhead Travelling Crane

Single girder electric overhead travelling cranes are widely used in machining, machine assembly, equipment maintenance, warehouse, and other work occasions.

Parameter

- Lifting Capacity: 20T

- Span: 7.5-24.5m

- Lifting height: 6m/9m/12m

- Work duty: A3

- Power Source: 380V/50Hz/3Ph

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Control Mode: Floor control / Remote control / Cabin room control

- Price: Customized Pricing

Application

20 Ton Low Headroom Single Girder Overhead Crane

The “Space-Efficient Design” feature in a Low Headroom Overhead Crane is specifically tailored to operate in environments with low-clearance buildings. This design optimization is crucial for maximizing the available lifting height while working within confined spaces.

Parameter

- Capacity: 20T

- Span length: 10.5-24.5m

- Lifting height: 6m/9m

- Work duty: A3

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

20 Ton Explosion Proof Single Girder Overhead Crane

The explosion-proof overhead crane is designed and manufactured to withstand explosions. Built on the foundation of standard bridge cranes, it is equipped with explosion-proof motors and electrical explosion proof components, along with other auxiliary mechanical explosion-proof measures, to ensure that the explosion-proof overhead crane does not cause fires, explosions, or other hazards when operating in explosive environments.

All components of the explosion-proof overhead crane are carefully selected for use in hazardous environments such as military handling, mining, chemical plants, refineries, wastewater treatment facilities, and painting workshops.

Parameter

- Capacity: 20T

- Span length: 10.5-24.5m

- Lifting height: 6m/9m/12m/14m

- Work duty: A3

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

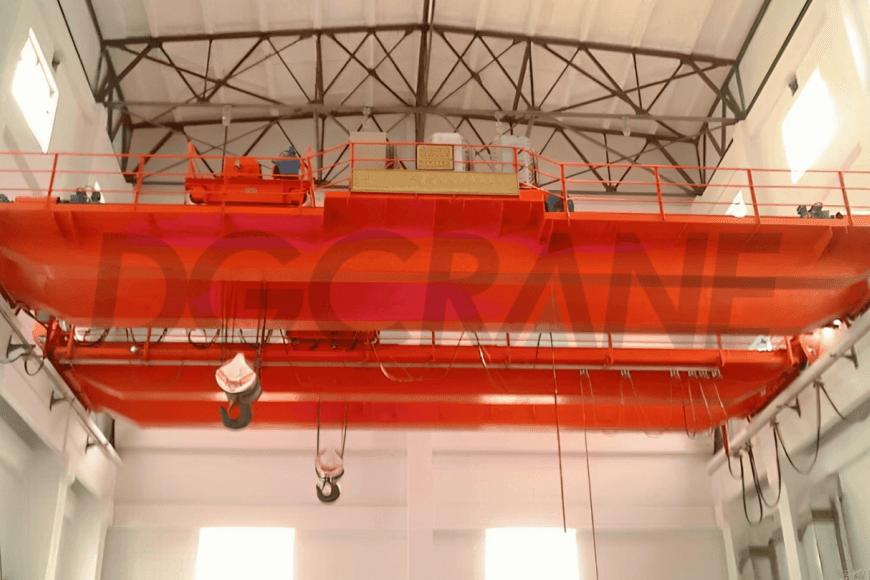

20 Ton LH-type Double Girder Overhead Crane with Hoist Trolley

The LH-type double girder overhead crane uses an electric hoist as the lifting mechanism and is mainly used for general lifting, loading, and unloading operations in mechanical manufacturing workshops, warehouses, assembly areas, stockyards, and power stations.

Parameter

- Capacity: 20T

- Span length: 7.5-31.5m

- Lifting height: 9/12/18m

- Work duty: A3

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

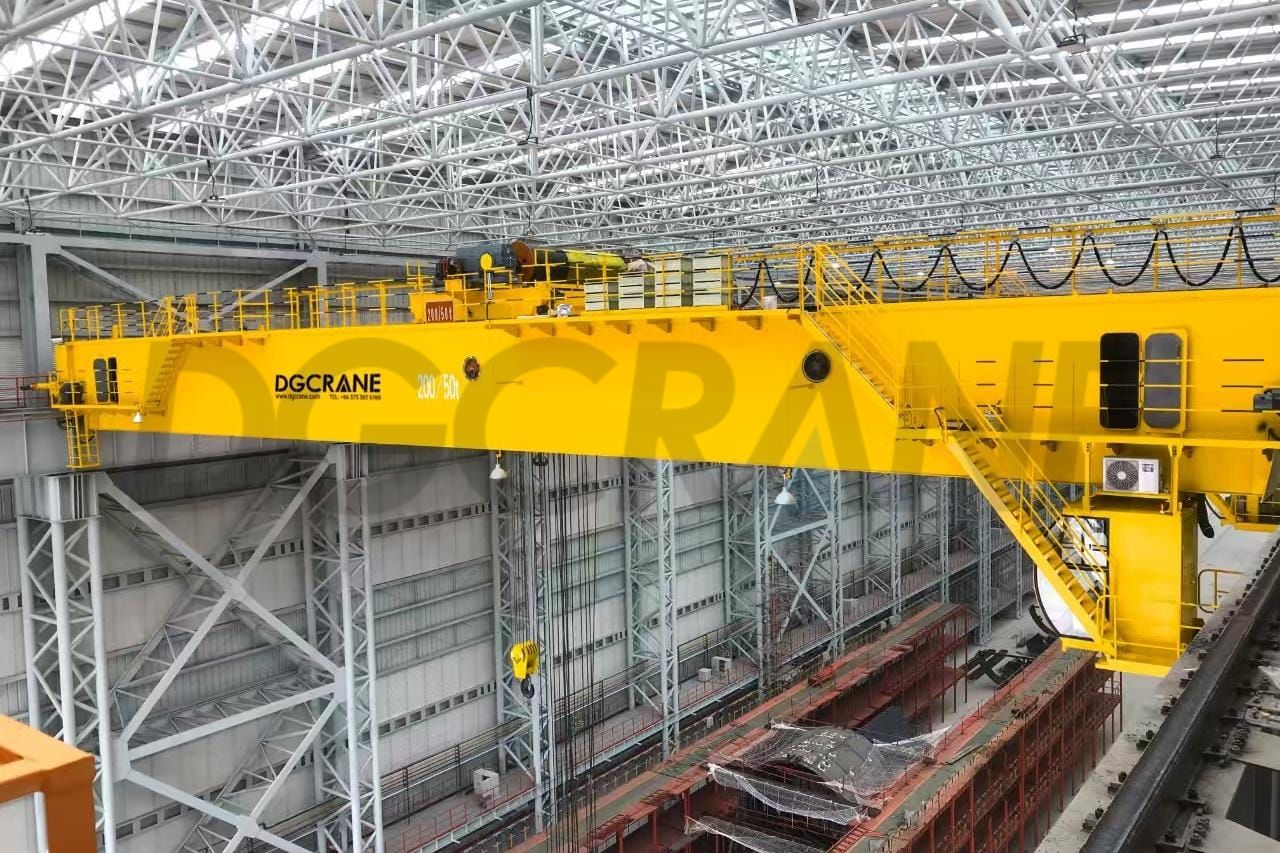

20 Ton QD-type Double Girder Overhead Crane with Winch Trolley

The QD-type double girder overhead crane uses a winch trolley as the lifting mechanism and is suitable for light to medium-duty operations in mechanical workshops, warehouses, material yards, and electricity generating plants for maintenance, assembly, and loading/unloading tasks.

Parameter

- Capacity: 20T

- Span length: 10.5-31.5m

- Lifting height:12m/14m

- Work duty: A5, A6

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

Application

20 Ton FEM Double Girder Overhead Crane

FEM double girder overhead crane‘s superior performance is embodied in the mature application of modular design, frequency conversion speed regulation, automatic detection, and other advanced technologies. The complete protection functions, such as overload protection, over current protection, and loss of voltage protection, make the crane application and working performance perfect.

Parameter

- Capacity: 20T

- Span length: 10.5-31.5m

- Lifting height: 18m

- Work duty: A5

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

20 Ton Grab Bucket Overhead Crane

Grab bucket overhead crane is a kind of lifting equipment that uses a grab as a fetching device for material stacking, inverting, fetching, loading and unloading. According to the suitable type of grab, different kinds of materials can be handled.

In actual production, the grab bucket overhead cranes are widely used. It can grab grain, ore, sand, scrap iron, garbage and other bulk goods, commonly used in power plants, yards, workshops, docks, and other places.

Parameter

- Capacity: 20T

- Span length: 10.5-31.5m

- Lifting height: 18m

- Work duty: A6, A8

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

20 Ton YZ Ladle Handling Cranes for Foundry

Ladle handling cranes are mainly used for transferring molten iron from the converter charging bay to the converter, transporting molten steel to the refining furnace in the refining bay, or lifting and moving molten steel to the ladle turret on the continuous casting machine in the steel receiving bay. They are one of the key pieces of equipment in the steelmaking continuous casting process.

Parameter

- Capacity: 20T

- Span length: 10.5-31.5m

- Lifting height: 12/14m

- Work duty: A7

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

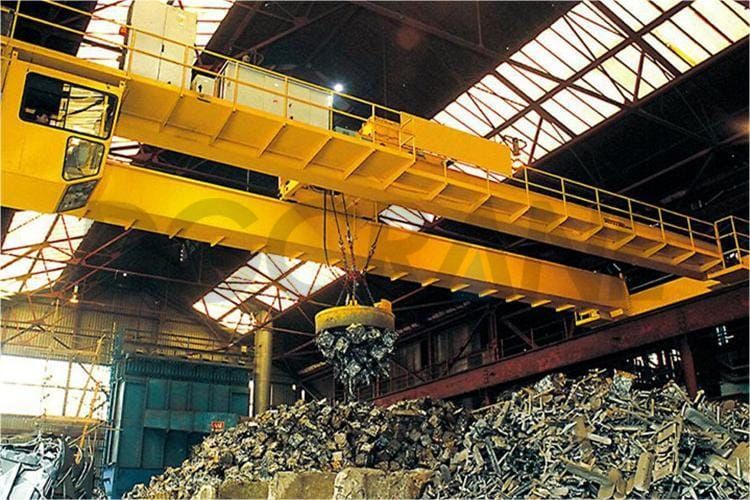

20 Ton Electromagnetic Overhead Cranes

Electromagnetic cranes have two types of lifting spreaders: the lifting magnet type and the magnet beam type. An electromagnetic overhead crane with a lifting magnet is mainly used in industries such as steel mills, foundries, scrap processing plants, machine workshops, steel storage facilities, and ports for lifting and transporting metal materials like cast iron ingots, steel balls, pig iron blocks, and machining chips.

Electromagnetic overhead cranes with magnet beam, on the other hand, use electromagnets installed beneath a hanging beam for material handling and are suitable for lifting long items such as steel plates, sections, bars, pipes, wires, and coils.

Parameter

- Capacity: 20T(10T+10T)

- Span length: 10.5-31.5m

- Lifting height: 12/14m

- Work duty: A6

- Rated voltage: 380V, 50-60Hz, 3ph AC

- Work environment temperature: -20℃~+40℃, relative humidity ≤85%

- Crane control mode: Floor control / Remote control / Cabin room

- Price: Customized Pricing

Application

20 Ton Overhead Crane Cases

With 0+ years of export experience, we provide customized crane solutions for design, production, and transport, serving 120+ countries. Backed by a 50+ member technical team, we’ve completed 3000+ projects across industries like steel, metallurgy, and paper.

25 Ton FEM Double Girder Overhead Crane Exported to Nigeria

This FEM double girder overhead crane is used to lift steel plates, steel tanks, and steel structures, we have designed two solutions for the customer, NLH type and QDX type, both of them can meet the crane use, and explain the difference between the two design, the customer finally chooses the QDX type, this design is similar to European type design, lifting mechanism is European winch type, all the mechanisms are controlled by VFD speed, all the brand components we chose is from China famous brand, has reliable quality.

Detailed specifications:

- Lifting capacity: 25 Ton

- Span: 20m

- Lifting height: 12m

- Lifting motor: Hongtai

- Lifting reducer: Boneng

- Lifting brake: Jiaozuo

- Cross traveling motor/reducer/brake: Boneng three in one

- Crane traveling motor/reducer/brake: Boneng three in one

- Electrical components: Schneider brand

- VFD: Schneider brand

- Power supply: 380V/50Hz/3Ph

- Control method: Cabin control+remote control

- Working class: M5

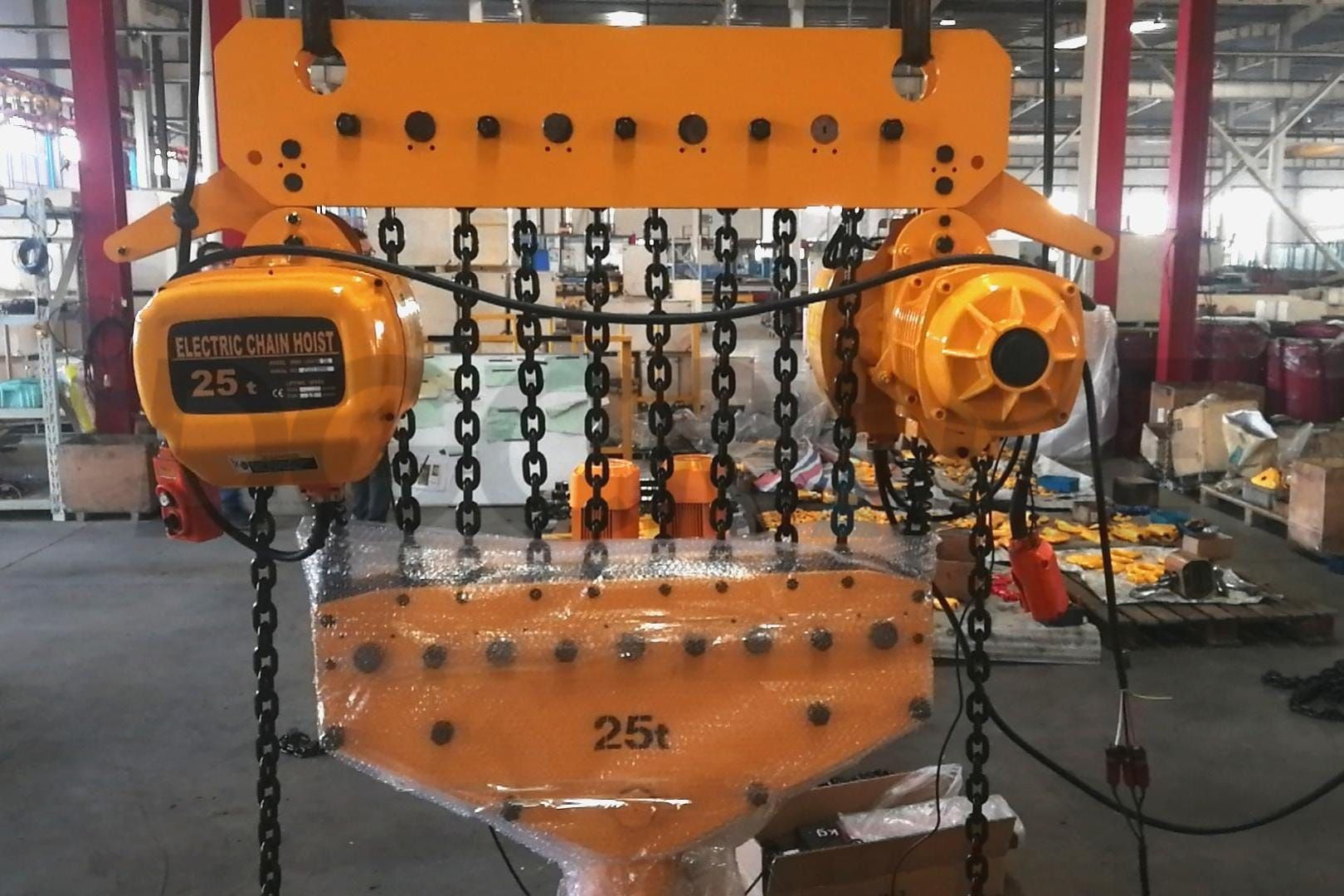

2 Sets of 25 Ton Single Girder Overhead Crane For Sale to Panama

Detailed specifications:

- Model: LD 25T Single girder overhead crane with electric chain hoist

- Lifting capacity: 25T

- Span: 11m

- Lifting height: 11m

- Crane traveling speed: 2-20 m/min

- Hoist Lifting speed: 1.3 m/min

Hoist traveling speed: 2/7 m/min (Double speed) - Power supply: 380V/50Hz/3Ph

- Work duty: M5

LH 25/5 Ton Double Girder Overhead Crane Exported to Zimbabwe

This order came through a recommendation from a customer in Uganda. One day, I received a call from a new contact expressing interest in a 20-ton single girder bridge crane — the same type and quality as the one we had previously supplied to Uganda. I quickly realized this inquiry came through a referral from our previous client. After the phone call, we continued to discuss the crane details via email.

Detailed specifications:

- Type: LH Double Girder Overhead Crane

- Capacity: 25/5ton

- Crane Span: 33m

- Lifting height: 19m

- Work class: ISO A3;

- Control mode: Pendant +Remote control

- Power source: 415V/50Hz/3Ph

- Installation site: Zimbabwe

Why choose DGCRANE‘s Overhead Crane?

- Superior Quality: All products are certified to ISO and CE safety standards. Key components such as motors and wire ropes are sourced from trusted international brands and are supported by a three-level quality inspection process.

- Efficient Delivery: With modular production and intelligent supply chain management, standard models are delivered in around 30 days, ensuring project timelines stay on track.

- Smart Technology: Optional PLC intelligent control systems and remote monitoring modules support features like dynamic load balancing, anti-sway algorithms, and self-diagnostic functions, boosting operational efficiency and reducing energy consumption.

- Tailored Solutions: Flexible customization of span, lifting height, and lifting devices to meet the unique requirements of industries such as steel, paper, and cement—ideal for complex working conditions.

20 Ton Overhead Crane FAQ

What is a 20 ton overhead crane?

A 20 ton overhead crane is a heavy-duty industrial lifting device composed of a bridge, trolley, hoisting mechanism, and rail system. It has a maximum lifting capacity of 20 tons and can move loads precisely in three-dimensional space. It comes in single-girder and double-girder configurations.

What are the typical applications of a 20 ton overhead crane?

It is widely used in steel plants, automotive manufacturing, power stations, shipyards, and warehouses for handling steel coils, machinery components, and heavy equipment. Customized versions (e.g., heat-resistant or explosion-proof) are available for extreme environments.

What functions can be customized for a 20 ton overhead crane?

Customizations include explosion-proof/heat-resistant designs, automated controls (variable frequency drives, remote monitoring), specialized lifting tools (electromagnetic clamps, rotating hooks), and energy-saving systems (regenerative braking). Smart models can integrate with IoT platforms.

How long does it take to install a 20 ton overhead crane?

Standard installation takes one week, including rail alignment, component assembly, and testing.

Can a 20 ton overhead crane be overloaded?

Overloading is strictly prohibited. The crane must operate within its rated 20-ton capacity. Exceeding this limit risks structural damage. For heavier loads, select a higher-capacity model (e.g., 25 tons or above).

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!