- INDUSTRIES

-

EQUIPMENT

-

Overhead Cranes

-

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

- Light Cranes

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US

Crane specification:

Single Girder Overhead Crane

Crane model: LD

Capacity: 2 ton

Span length: 14m

Lifting height: 10m

Work duty: A4

Power source: 380V/50Hz/3Ph

Control mode: Pendant + remote control

QTY: 3 sets

Double Girder Overhead Crane

Crane model: NLH

Capacity: 6 ton

Span length: 21m

Lifting height: 7m

Work duty: A5

Power source: 380V/50Hz/3Ph

Control mode: Pendant + remote control

QTY: 2 sets

Single Girder Semi Gantry Crane

Crane model: BMH

Capacity: 2 ton

Span length: 7m

Lifting height: 5m

Work duty: A5

Power source: 380V/50Hz/3Ph

Control mode: Pendant + remote control

QTY: 6 sets

The initial inquiry was received on July 8th, with the client requesting multiple overhead cranes, a gantry crane, and a wall-traveling jib crane. In the first communication, the client provided approximate parameters but had not yet determined the specific quantities. Based on their requirements, we recommended a traditional Chinese design solution.

The client mentioned plans to visit China in October, so we provided an invitation letter. As scheduled, the client, accompanied by a crane installation technician, visited our factory from October 28th to 29th.

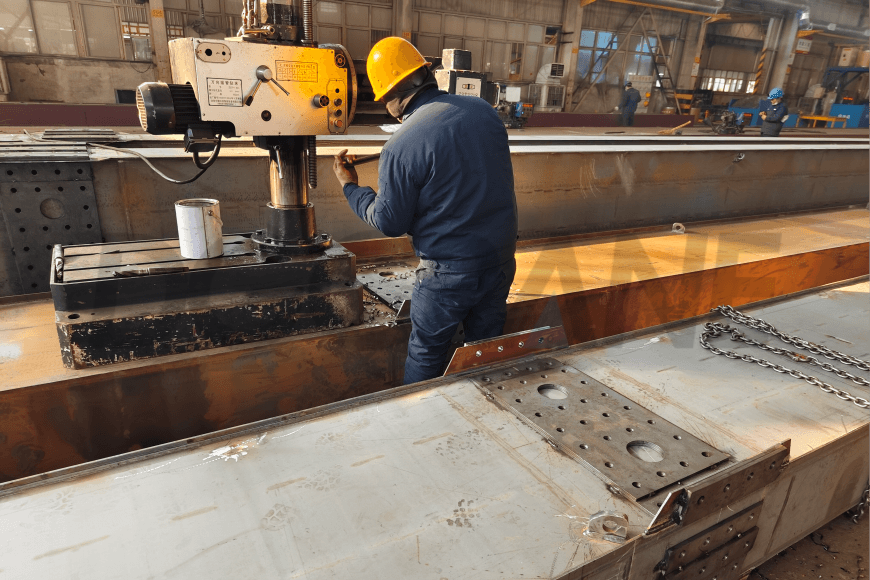

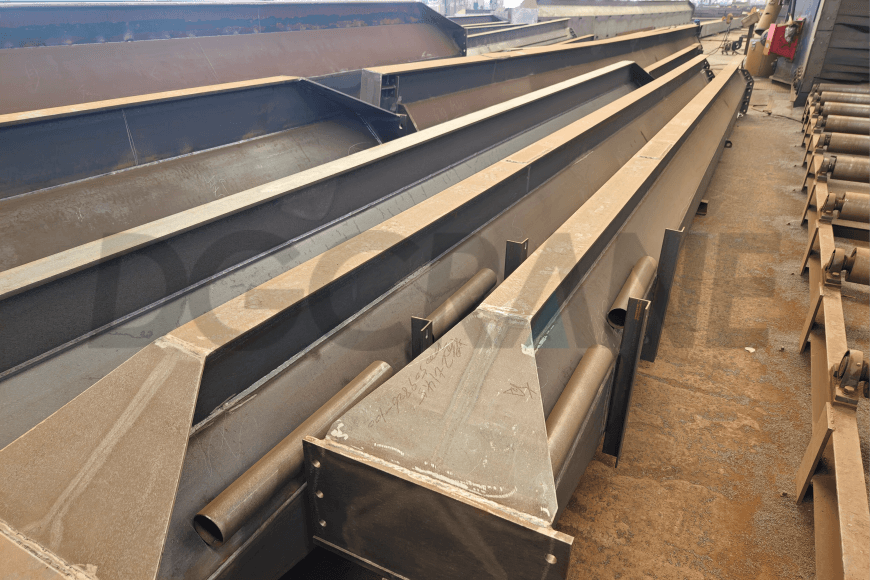

In the morning, we guided the client through our production workshops for both single girder overhead cranes and double girder overhead cranes, as well as the gantry crane workshop. We explained the welding and painting processes for the main beam. Given the size limitations of container transportation, we demonstrated where the main beam would be disconnected for shipping and how it would be reassembled upon installation, including our packaging methods.

During the visit, the client showed particular interest in the single girder semi gantry crane in the workshop, noting that it matched their requirements. They requested specific customizations, including a trackless ground girder, an F-series motor to save space between the legs, and a steel cage protective frame for the motor on the ground beam. All these requests can be accommodated.

Additionally, since the ground beam is designed without rails, we suggested adding guide wheels to the end beam. This would help protect the wheels running on the track and prevent derailment, ensuring smoother and safer operation.

After the morning visit, we returned to the office and had a detailed communication on the number of cranes, tonnage, span, lifting height, crane layout, configuration, delivery time and quantity required by the client.

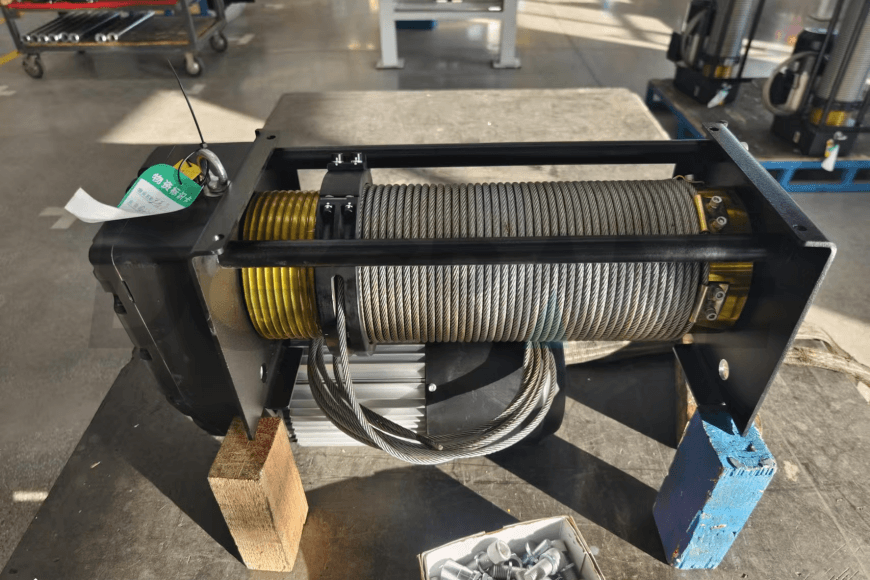

In the afternoon, we took the client to visit the production workshops of traditional Chinese electric hoists and European electric hoists, including motor production and load testing, wiring, hoist assembly and load testing. We also visited the production workshops of reducers, wheels, hooks and drums, and the client was deeply impressed.

Since the client is familiar with crane products and also engage equipment installation and commissioning work in South Africa, the client is very satisfied with the quality of our products. One week after the client returned to South Africa, we finalized the content and details of the contract. The first batch of orders included 11sets cranes. The crane order was put into production at the end of November and completed in mid-January. We shipped those 11sets crane before Chinese New Year holiday.

Below are the pictures of the production.

The client received the goods at the end of February and started the installation in early March. We provided the client with the general installation drawing and electrical drawings for reference. The clients installed those cranes by themselves. The installation was completed within 2 weeks and 2 installation pictures were sent.

Thus, the order for the first batch of projects was successfully completed. This is a quite pleasant cooperation, we are currently in the process of communicating the details of the second batch of orders.

For any crane demands, please feel free to contact DGCRANE. You will always get the best products and service from us!

Zora Zhao

Expert in Overhead Crane/Gantry Crane/Jib Crane/Crane Parts Solutions

With 10+ years of experience in the Crane Overseas Export Industry, helped 10,000+ customers with their pre-sales questions and concerns, if you have any related needs, please feel free to contact me!

WhatsApp: +86 158 3611 5029

Email: zorazhao@dgcrane.com

Related Cases

Subscribe to our newsletter

The latest DGCRANE price list, news, articles, and resources.

- Overhead Cranes

- Low Headroom Overhead Cranes

- Double Girder Overhead Crane

- Grab Bucket Overhead Crane

- Top Running Overhead Crane: Wide Application and Easy Maintenance

- Coker Cranes for Harsh Environments: High Temperature and Corrosion Resistant Design

- Single Girder Overhead Cranes

- Eot Cranes

- Eot Crane

- Single Girder Eot Cranes

- Double Girder Eot Cranes

- Underslung Cranes

- Gantry Cranes

- Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

- Truss Gantry Cranes: Cost-Effective, Wind-Resistant, and Perfect for Large Spans

- Gantry Crane

- Different Types of Small Portable Aluminium Gantry Cranes: Cost Effective

- Single Girder Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Casting Yard Gantry Cranes

- Container Gantry Cranes (RMG)

- Portable Gantry Cranes

- FEM Standard Crane & Hoist

- FEM Standard Overhead Cranes

- FEM Standard Gantry Cranes

- FEM Standard Jib Cranes

- FEM Standard Wire Rope Electric Hoists

- FEM Standard Electric Chain Hoists

- Hoist & Winch Trolley

- Low Headroom Wire Rope Electric Hoist: Compact Design for Efficient Lifting in Tight Spaces

- Electric Hoist for Molten Metal: High-Temperature, Safe Lifting for Metallurgical Environments

- Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

- 6 Double Girder Trolley Electric Hoists for Overhead Cranes: Custom Solutions for Every Lifting Need

- Manual Chain Hoists: Alloy Steel Construction for Smooth and Safe Lifting

- Electric Wire Rope Hoists

- Chain Hoists

- Crane Trolley

- Electric Winch

- Port Cranes

- Rubber Tyred Container Gantry Crane

- Ship To Shore Crane

- Container Straddle Carrier

- Harbour Portal Crane

- Shipyard Portal Cranes

- Reliable Versatile Electric Transfer Carts

- Powerful Heavy Duty Coil Transfer Carts

- Powerful Pallet Transfer Carts

- Rail Transfer Carts

- Reliable Heavy Duty Ladle Transfer Cars

- RGV Transfer Carts

- Superior Die Transfer Carts

- Trackless Transfer Carts

CRANE PARTS

- Special Cranes

- Rail Mounted Container Gantry Crane

- Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

- Charging Cranes for Steel Production: Safe and Reliable Solutions for Efficient Material Handling

- Insulated Overhead Cranes for Safe Non-Ferrous Metal Smelting

- Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

- Quenching Overhead Crane for Heat Treatment Plant: High-Temperature Insulated and Efficient Lifting Solution

- Heavy Duty Forging Cranes: Durable, High-Capacity Solutions for Forging

- Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

- 35-65t Clamp Overhead Crane

- Boat Hoists

- Yacht Davit Crane

- Boat Jib Crane

INDUSTRIES

COMPANY

- sales@dgcrane.com

- +86-373-3876188

- +86 158 3611 5029

- Floor 30,Gongyuan INT'I Building, Jinsui Road, Xinxiang City, Henan Province, China