Port Crane Wheels for Harbour Crane

Port lifting machinery is widely used in port logistics and the freight industry. It can improve logistics efficiency and freight speed, shorten the turnaround cycle, and save costs. Specific application scenarios include quay loading and unloading operations, yard transfer operations, and stack transfer operations.

The selection of port crane wheels is a process that comprehensively considers various factors, including the shape of the wheel tread, material, application scenarios, and specific dimensions. When selecting, one should choose the most suitable wheel type and specifications based on the specific type of crane, working conditions, and performance requirements.

Crane wheels are mainly used in L block crane wheels, 45°split bearing box-type crane wheels and Round Bearing Box Crane Wheel Assembly (European Type). The commonly used specifications are Φ550, Φ630, Φ800, Φ1000 and so on.

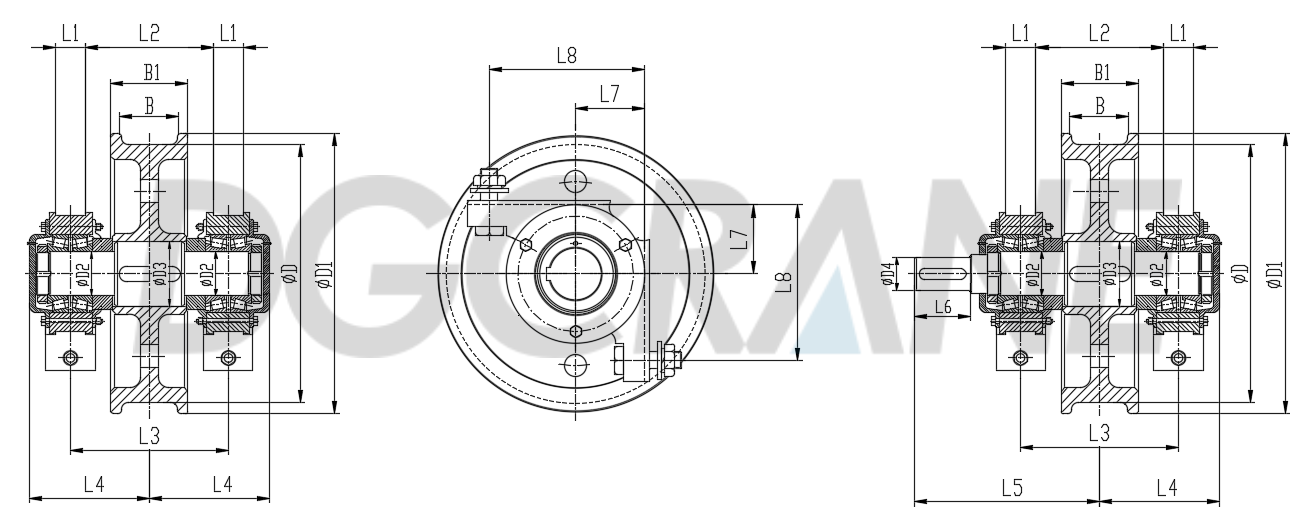

L block crane wheel assembly

Features:

- Angle box-type wheel sets typically feature an angular bearing box structure.

- They are suitable for heavy loads and frequent working conditions.

- Installation errors of the wheel sets can be manually adjusted and compensated to ensure assembly precision.

Parameters

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 50 | 230 | 280 | 230 | 400 | 105 | 140 | 310 | 271~293 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 264~286 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 80~150 | 130~210 | 50 | 230 | 280 | 230 | 415 | 130 | 140 | 310 | 316~381 | |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 306~381 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 80 | 235 | 315 | 260 | 455 | 130 | 160 | 350 | 502~542 |

| Passive crane wheels ø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 80 | 235 | 315 | 260 | / | / | 160 | 350 | 489~534 |

| Active crane wheels ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 90 | 275 | 365 | 300 | 500 | 130 | 190 | 410 | 742~823 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 90 | 275 | 365 | 300 | / | / | 190 | 410 | 729~810 |

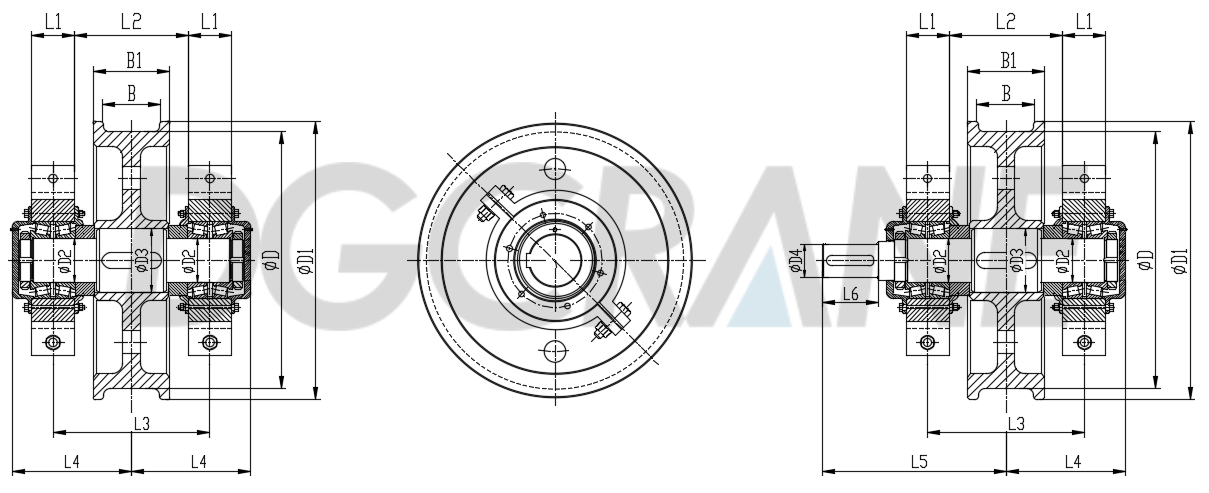

45°split bearing box-type crane wheel assembly

Features:

- The bearing housing is designed with a 45-degree split, effectively reducing the contact stress between the wheel and the track, thereby extending the wheel’s service life.

- The 45° split design ensures a more even stress distribution on the wheel, reducing local stress concentration and enhancing the wheel’s durability and stability.

- Capable of stable operation under various complex working conditions, including high temperature, high humidity, and dusty environments.

- The 45° split design makes the wheels easier to disassemble and replace, reducing maintenance time and costs.

Parameters

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 100 | 180 | 280 | 230 | 400 | 105 | 276~298 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 100 | 180 | 280 | 230 | / | / | 269~291 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 85 | 80~150 | 130~210 | 100 | 180 | 280 | 230 | 415 | 130 | 321~386 |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 100 | 180 | 280 | 230 | / | / | 311~386 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 120 | 195 | 315 | 260 | 455 | 130 | 507~547 |

| Passive crane wheelsø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 120 | 195 | 315 | 260 | / | / | 494~539 |

| Active crane wheel ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 140 | 225 | 365 | 300 | 500 | 130 | 747~828 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 140 | 225 | 365 | 300 | / | / | 734~815 |

Round Bearing Box Crane Wheel Assembly (European Type)

Features:

- Lightweight and compact in size.

- Easy to install and maintain, with a compact structure that is easy to assemble and ensures high assembly precision.

- Smooth operation with high-strength alloy steel wheels, offering wear resistance, low noise, and long service life.

Refer to the following table for detailed parameters:

Application

DGCRANE has had professional export crane wheels for 13 years, for you to customize the most suitable crane and transportation solutions, provide installation and maintenance services, and support product third-party testing.

For any demands related to the crane wheels, please feel free to contact me.