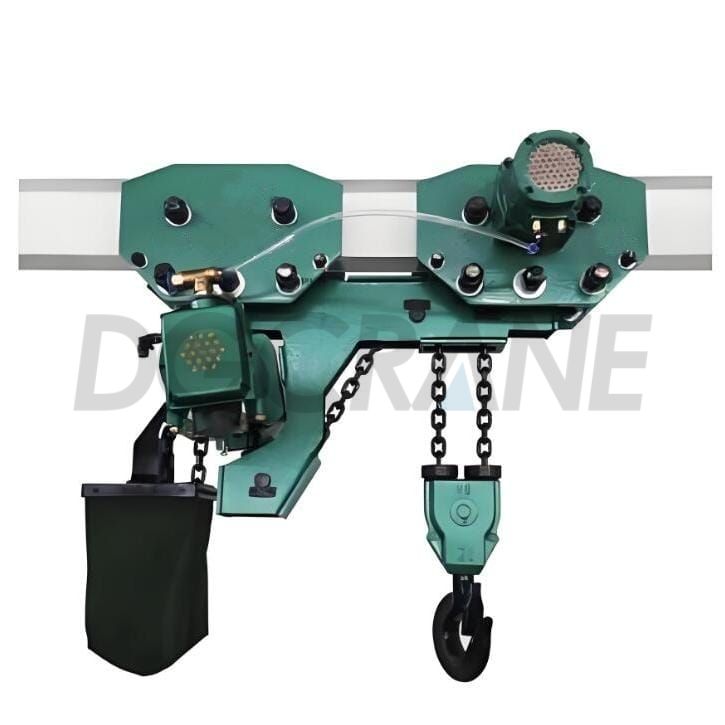

Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

A pneumatic motor drives the pneumatic (air) chain hoists to operate the lifting and lowering functions, with compressed air as the primary power source. This equipment is typically suitable for environments with high explosion-proof requirements, especially in locations where combustible gases or dust are present, such as chemical plants, oil fields, and mines.

Features of Pneumatic (Air) Chain Hoists:

- Excellent Explosion-Proof Performance: Pneumatic (air) chain hoists do not generate electric sparks, making them suitable for flammable and explosive environments.

- No Overload Risk: Due to the characteristics of the pneumatic system, when the load exceeds the rated value, the pneumatic (air) chain hoists automatically stop running instead of causing motor burnout like electric hoists.

- High-Frequency Operation Capability: Pneumatic (air) chain hoists can operate continuously in high-frequency work environments without overheating, making them especially suitable for assembly lines and continuous production processes.

- Flexible Operation: The control of pneumatic (air) chain hoists is usually simple and responsive, allowing for precise load positioning.

- Compact and Lightweight: Due to the simple structure of the pneumatic motor, pneumatic (air) chain hoists are typically lightweight, making them easy to install and move.

- Low Maintenance Costs: The simple design of pneumatic (air) chain hoists makes them easy to maintain, with fewer electrical components and lower failure rates.

- Wide Temperature Range: Pneumatic (air) chain hoists can operate across a broad temperature range, maintaining stable performance even in extreme conditions.

Parameters

For detailed product information, please refer to the PDF.

Pneumatic (Air) Chain Hoists VS Electric Chain Hoists

| Feature | Pneumatic(Air)Chain Hoists | Electric Chain Hoists |

|---|---|---|

| Power | 0.6MPa compressed air | 220V-440V voltage |

| Running Speed | Adjustable, fast (4 times faster than electric) | Not adjustable, slower |

| Safety | No sparks or electric shocks | Risk of electric leakage, sparks, and electric shock |

| Structure | Pneumatic motor is simpler and compact | Electric motor is large, heavy, requires many parts to prevent sparks |

| Wiring | No cables needed, simple air hose connection, no need for professional operators | Requires professional installation, more complex |

| High-Temperature Operation | Can work in temperatures above 60°C | Malfunctions in high temperatures |

| Weight | Light | Heavier |

| Maintenance | Can be maintained without professional training | Requires professional maintenance |

| Lifespan | High precision parts, suitable for frequent use, long lifespan | Low efficiency electric motor, many parts prone to wear, shorter lifespan |

| Feature | Pneumatic(Air)Chain Hoists | Electric Chain Hoists |

|---|---|---|

| Advantages | Explosion-proof: Can be safely used in environments with explosion risks, such as refineries. | High Lifting Capacity: Electric hoists can handle heavier loads compared to pneumatic hoists, making them suitable for heavy-duty applications. |

| Compact and Portable: Light weight design makes it easy to transport and operate, enhancing versatility. | Quiet Operation: They run quietly, which is crucial in noise-sensitive environments. | |

| Load Control: Offers precise load control, making it ideal for delicate operations. | Precise Control: Electric hoists can provide precise load positioning control. | |

| Disadvantages | Limited Lifting Capacity: Pneumatic hoists may be limited in lifting compared to electric hoists. | Limited Portability: Electric hoists rely on a power source, making them less portable than pneumatic hoists. |

| Noise: Due to compressed air operation, they can generate noise, which may not be suitable for noise-sensitive environments. | Risk of Overheating: Prolonged use of electric hoists may cause overheating, requiring a cooling period. |

We are dedicated to providing tailored pneumatic hoist solutions based on your specific usage conditions and requirements. Whether you need to handle heavy loads, perform precision tasks, or operate in specialized environments, our professional team can design the most suitable pneumatic hoist for you.