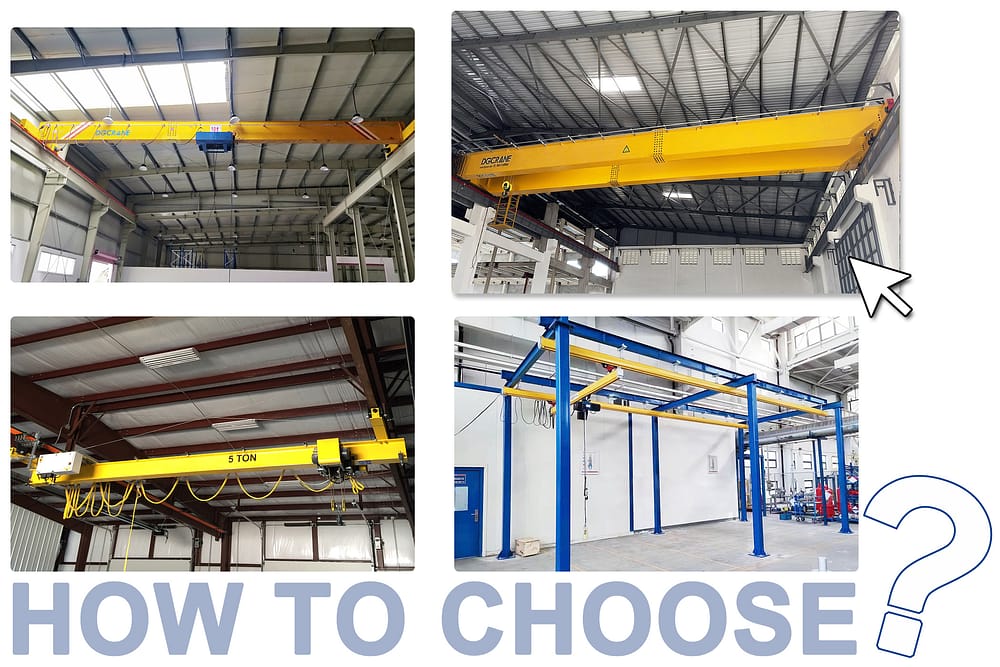

Demystifying Overhead Crane Selection: Insider Tips from a 10+ Year Industry Specialist

Overhead cranes also known as bridge cranes, girder cranes or OH cranes. Overhead cranes are some of the popular equipment inside the material handling industry. About overhead cranes, we in the process of communication with customers, and Quora someone’s inquiries, to extract a few frequently asked questions:

Overhead cranes also known as bridge cranes, girder cranes or OH cranes. Overhead cranes are some of the popular equipment inside the material handling industry. About overhead cranes, we in the process of communication with customers, and Quora someone’s inquiries, to extract a few frequently asked questions:

- What are the different types of overhead cranes?

- How do I choose the right overhead crane?

- Where are overhead cranes used?

- What is the cost of an overhead crane?

Overhead Crane Types

Single Girder Overhead Crane

Single Girder Overhead Crane-Low headroom overhead cranes maximize the height of lift.

Single girder overhead cranes-also known as single girder overhead travelling cranes/single beam overhead cranes are our most popular type of overhead cranes as they provide the most cost-effective lifting solution for all capacities 0.5ton to 20tonnes and upto 28.5mtr span for indoor or outdoor applications.- Standard Capacity: 1t/2t/3t/5t/10t/16t/20t or customized on demand, manual type upto 5ton

- Span length: 7.5m-28.5m, manual type 4m-12m

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: A3/A4, manual type A1

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC or Manual Mode

- Crane control mode: Floor control / Remote control

| Reasons to choose single girder overhead cranes | Reasons for not choosing single girder overhead travelling cranes |

|---|---|

|

|

Double Girder Overhead Crane

Double girder overhead crane successfully installed at customer’s plant in Tanzania

With a lifting capacity of up to 800 ton and standard spans of up to 34m, the double girder overhead travelling crane makes it possible to handle unwieldy loads safely and precisely. Through different designs with different spreaders to realize the function of grabbing various materials, it is the type of heavy duty overhead crane that covers the widest range of industries. |

|

|

|---|---|---|

|

Casting cranes are key equipment in the steelmaking process in steel mills and are suitable for use in harsh working environments with high temperatures, high levels of dust and noxious gases. |

Clamping overhead cranes are often used in steel mills or warehouse workshops where billets, slabs, ingots, coils, profiles and other items are clamped, and other working conditions. |

Grab type overhead cranes are often used in bulk material handling, timber handling, garbage grabbing and other environments. |

- Capacity: 5-800/150ton

- Span length: 10.5-34m

- Lifting height: 12-50m

- Work duty: A4, A5, A6,A7

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control / Cabin room

| Reasons to choose double girder overhead cranes | Reasons for not choosing double girder overhead cranes |

|---|---|

|

|

Underhung Cranes

Underhung cranes—sometimes referred to as underhung overhead cranes, under running overhead cranes. Underhung cranes are the choice when there is insufficient space in the upper part of the plant, or there is no conventional crane runway but the roof can be stressed.

Underhung cranes—sometimes referred to as underhung overhead cranes, under running overhead cranes. Underhung cranes are the choice when there is insufficient space in the upper part of the plant, or there is no conventional crane runway but the roof can be stressed.

- Capacity: 0.5ton/1ton/2ton/3ton/5ton/10ton

- Span length: 5.5m-16.5m

- Lifting height: 6m/9m/12m/18m/24m/30m, manual type upto10m

- Work duty: A3/A4, manual type A1

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC / Manual Mode

- Crane control mode: Ground control / Remote control

| Reasons for choosing underhung cranes | Reasons for not choosing underhung cranes |

|---|---|

|

|

Workstation Overhead Crane

Workstation overhead cranes are a kind of combined suspension overhead crane, also called workstation bridge crane, freestanding overhead crane. The modular design makes installation and modular design of workstation overhead cranes makes installation and modification more convenient. The lower frictional resistance results in quieter and smoother operation.

Workstation overhead cranes are a kind of combined suspension overhead crane, also called workstation bridge crane, freestanding overhead crane. The modular design makes installation and modular design of workstation overhead cranes makes installation and modification more convenient. The lower frictional resistance results in quieter and smoother operation.

- Capacity: 125kg to 2000kg

- Work duty: M3,M4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

| Reasons for choosing workstation overhead cranes | Reasons for not selecting workstation overhead cranes |

|---|---|

|

|

Monorail Overhead Crane

Monorail overhead cranes usually refer to the type of overhead cranes where the main beam is a fixed I-beam and the hoist runs and lifts on the I-beam. These cranes can only move in two directions, in the vertical direction (up / down) or on the Y axis and in the horizontal direction along monorail beam or on the X axis. While single girder overhead crane able to move in three directions or more on the X, Y, Z axis and move radius in the vertical axis.

Monorail overhead cranes usually refer to the type of overhead cranes where the main beam is a fixed I-beam and the hoist runs and lifts on the I-beam. These cranes can only move in two directions, in the vertical direction (up / down) or on the Y axis and in the horizontal direction along monorail beam or on the X axis. While single girder overhead crane able to move in three directions or more on the X, Y, Z axis and move radius in the vertical axis.

- Capacity: 0.5ton/1ton/2ton/3ton/5ton/10ton

- Lifting height: 6m/9m/12m/18m/24m/30m

- Work duty: M3/M4

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Floor control / Remote control

| Reasons to choose monorail overhead cranes | Reasons not to choose monorail overhead cranes |

|---|---|

|

|

FEM Standard Overhead Crane

FEM Standard overhead crane successfully installed at customer’s plant in Tanzania

The most outstanding feature of FEM standard overhead cranes is that the drive mechanism adopts a three-in-one reducer (hardened gear reducer, inverter brake motor), so the structure is also more compact. It is precisely because of this special design that the blind spot range of the overhead crane is smaller in the front and back, so that it can utilize the production area to a greater extent. The brake pads inside the three-in-one gear motor are maintenance-free for life, which can save the maintenance cost in the later stage.- Capacity: 1-20ton

- Span length: 9.5-24m

- Lifting height: 6m/9m/12m/18m or customized according to clients’ site conditions

- Work duty: A5

- Rated voltage: 220V/380V/400V/415V/660V, 50-60Hz, 3ph AC

- Crane control mode: Pendant control / Remote control

| Reasons for choosing FEM standard overhead crane | Reasons not to choose the FEM standard overhead crane |

|---|---|

|

|

EOT Cranes:Electric Overhead Travelling Crane

Distinguished from manually powered overhead cranes, it is the most widely used type of overhead crane. There is some overlap with bridge cranes in some classifications. There will be a special page for you to expand on eot crane. https://www.dgcrane.com/eot-cranes/Overhead Crane Selection Guide Summary – Suggest Bookmark

Single Girder Overhead Crane

- Suitable for lifting capacity up to 20t.

- Simple structure, easy to install, easy to transport.

- Flexible operation, can be ground operated (follow the hoist to move or move independently), can be remote-controlled, operation program options.

- Wide range of applications for small loads and equipment installation and maintenance.

Double Girder Overhead Crane

- Lifting capacity of 20t and above.

- Can be matched with different spreaders to suit different material gripping needs, a wide range of applications.

- In addition to the general operating environment, it can also be used in higher working levels and in harsh environments, such as steel mills, or explosion-proof environments.

- Durable, high fatigue strength of the main load-bearing components, longer service life.

- Sufficient dynamic stiffness and structural stability, when equipped with a driver’s cab, is more favorable to the safety and health of the operator.

Underhung Cranes

- Suitable for lifting capacity up to 10t.

- Suitable for use when there is no running beam system in the structure of the plant, but the roof is load-bearing and a load-bearing rail can be installed underneath the roof for the traveling of large vehicles.

Workstation Overhead Crane

- Suitable for lifting capacities up to 2t.

- Free and flexible lifting solutions for small tonnages, small spans and light work levels.

- Mainly used in various assembly line operations.

Monorail Overhead Crane

- Suitable for lifting capacities up to 10t.

- According to the process flow of the production plant, the route or direction of the crane track is arranged, which can be a circular route.

- Suitable for small tonnage, fixed production line place.

- Can be equipped with different hoisting equipment such as wire rope hoists and chain hoists.

FEM Standard Overhead Crane

- More compact structure, low headroom height, small blind spot size of the hook, covering a larger operating range of the plant.

- Light weight, small wheel pressure, low load bearing requirement for steel structure of plant, can effectively reduce the cost of plant construction.

- Frequency conversion speed control of the whole vehicle can realize stepless speed control, wider speed range, speed control ratio of 1:10.

- Black box (safety monitoring system) can be added.

Overhead Crane Prices

For the overhead crane pricing, since overhead cranes are customized products based on specific factory specifics, we can’t give you the exact price directly, but we can still provide a price reference range. Gives you an idea of what percentage of the overhead crane cost is in your purchasing program.Single Girder Overhead Crane Price List (Reference)

| Products | Span/m | Lifting Height/m | Power Supply Voltage | Price/USD |

|---|---|---|---|---|

| 1 ton overhead crane | 7.5-28.5 | 6-30 | 220-480/3/50 | $1,830-5,100 |

| 2 ton overhead crane | 7.5-28.5 | 6-30 | 220-480/3/50 | $2,000-5,900 |

| 3 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $2,130-15,760 |

| 5 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $3,130-16,760 |

| 10 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $3,890-20,000 |

| 16 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $4,180-23,400 |

| 20 ton overhead crane | 7.5-37.5 | 6-30 | 220-480/3/50 | $7,100-28,600 |

Double Girder Overhead Crane Price

The price of double girder overhead cranes is more complicated to quote because of the variety of configuration combinations, but you can be able to have a price reference based on these real examples of quotes below. |

|

|---|---|

|

|

|

|

|

|

They may not match your needs, as a customized expert of bridge cranes who has been engaged for 10+ years, you are welcome to contact me anytime!

No the type of overhead crane you’re looking for?

Provide information about your need to your dedicated customer service now!

Or leave your information for our service team.No current demand, but would like to get a new price list.

Prices will be updated from time to time, If you want to get the latest price list the first time, leave your email, and we will send it out for you as soon as possible.

FAQs

Overhead crane installation is a service that is generally offered by suppliers, either by sending an engineer on site or by providing some online installation tutorials. We have created a single girder overhead crane installation tutorial (infographic/PDF) to help you quickly understand the steps.

- Installation infographic: 9-Steps-Quick-Installation-Single-Girder-Overhead-Crane.png (900×4243) (dgcrane.com)

- Installation instructions document: Installation and Commissioning of Overhead Crane

- Konecranes: Konecranes is a well-known Finnish manufacturer of lifting equipment, offering various types of cranes and material handling solutions. They serve various industries worldwide, including manufacturing, ports and logistics, mining, and more.

- Demag Cranes: Demag Cranes, headquartered in Germany, is a globally recognized crane manufacturer. They produce various types of cranes, including bridge cranes and gantry cranes.

- Terex: Terex is a diversified American engineering and heavy machinery manufacturer, offering a range of lifting equipment, including bridge cranes.

- Cranes-UK: Cranes-UK is a UK-based supplier specializing in the sale, rental, and maintenance of various types of cranes, including bridge cranes. They provide both new and used equipment.

- STAHL CraneSystems: STAHL CraneSystems, based in Germany, is a crane equipment manufacturer that focuses on applications in explosive environments, providing high-quality explosion-proof cranes.

- Street Crane: Street Crane is a UK-based crane equipment manufacturer, offering various types of bridge cranes. They cater to multiple industries, including manufacturing, construction, and ports.

- ABUS: ABUS is a German company that manufactures bridge cranes, gantry cranes, and hoists, providing various solutions, including custom designs.

These are just a few of the internationally renowned bridge crane suppliers. Depending on your specific requirements, location, and budget, you can select an appropriate supplier to meet your lifting equipment needs. Be sure to work with suppliers to understand their products, services, and support to ensure they meet your project’s requirements.

- Jiangsu Province: Jiangsu Province holds a prominent position in China’s crane manufacturing industry. Cities such as Suzhou, Nanjing, Changzhou and Xuzhou are home to numerous crane manufacturers and suppliers covering a wide range of crane types.

- Henan Province: Xinxiang City in Henan Province is one of the important crane manufacturing bases in China. These areas are home to several well-known manufacturers of overhead cranes, supplying crane equipment to both the domestic and international markets.

- Chongqing: Chongqing has a large number of crane manufacturers in the southwest region. Crane products manufactured here are widely used in ports, mines and construction.

- Guangdong Province: Crane manufacturers are also found in the cities of Zhuhai, Guangzhou and Shenzhen in Guangdong Province. They produce various types of overhead cranes and material handling equipment to meet the needs of different industries.

- Shandong Province: The cities of Qingdao, Jinan and Weifang in Shandong Province have a number of crane manufacturers. These companies produce overhead cranes and gantry cranes for the domestic and international markets.

- Liaoning Province: Dalian and Shenyang in Liaoning Province are the crane manufacturing bases in the northeast region, providing many types of cranes and related equipment.

- Hunan Province: Changsha, Hunan Province also has a number of crane manufacturers who produce bridge cranes, gantry cranes and tower cranes.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!