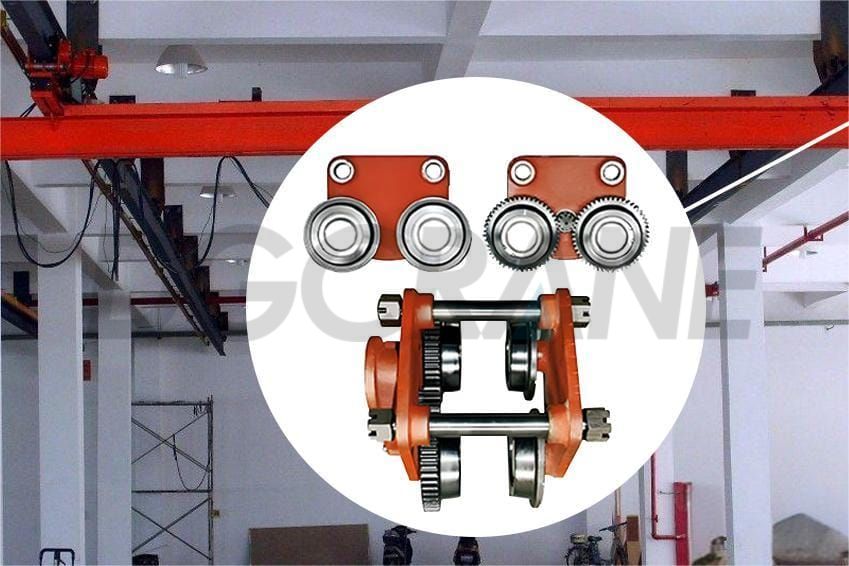

Overhead Crane Wheels Block Assembly

Overhead crane wheels are critical components in the crane’s traveling mechanism, bearing heavy loads and ensuring the safe guidance of the crane along a predetermined track. In overhead cranes, the main wheel sets used include LD gear crane wheel sets, hoist trolley wheel sets, round bearing housing wheel sets, round bearing box crane wheel assembly, and 45°split bearing box crane wheel assembly.

These are suitable for various types of overhead crane traveling mechanisms, such as electric single-girder cranes, electric single-girder suspension cranes, double-girder overhead cranes, and foundry overhead cranes.

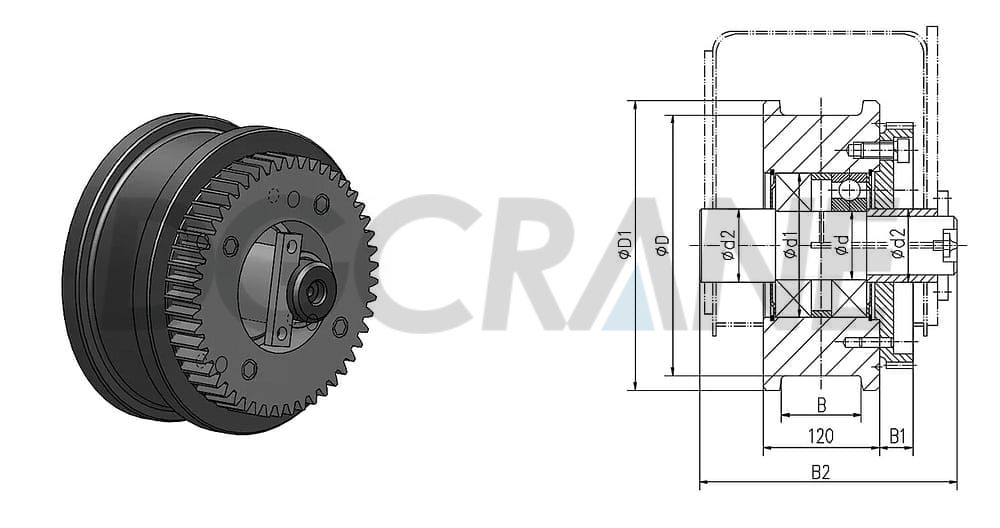

LD Gear Crane Wheel Assembly

The LD gear crane wheel assembly is a device used to support the crane and its load, enabling the crane to move back and forth along the track. It is an important component of the crane’s traveling mechanism.

Components:

The LD gear crane wheel assembly consists of four parts: wheel shaft, wheel rim, bearing, and gear ring. The primary material for the LD gear crane wheel is 45# steel, which is surface-hardened to provide good quality at a low cost.

Materials:

- The wheel shaft is made of 45# steel, with tempering treatment, achieving a hardness of HB217-HB255. It features grease holes for lubrication.

- The wheel rim is cast from 45# steel, then finely machined and surface-hardened. The tread surface has a hardness of HB300-HB380, with a hardened layer thickness of 8mm-12mm and a hardness of no less than HB260 at a depth of 10mm.

- The outer surface of the wheel is coated with black anti-rust paint to prevent corrosion.

- The bearings are deep groove ball bearings, with main models including 314, 412, 318, and 414. Each set of LD wheels includes two driving wheels, two driven wheels, and the corresponding LD shaft.

Parameters:

The specifications for LD gear crane wheel assembly mainly include two sizes: Φ300 and Φ400, with groove widths of 70mm and 90mm. Other diameters can also be custom-made to non-standard specifications.

| Model | D | D1 | d | d1 | d2 | B | B1 | B2 |

|---|---|---|---|---|---|---|---|---|

| LD300 | ø270 | ø300 | ø70 | ø150 | ø75 | 70 | 38 | 270 |

| LD400 | ø370 | ø400 | ø90 | ø190 | ø100 | 90 | 40 | 280 |

Features:

- The LD gear crane wheel assembly does not have a bearing box; the bearing is directly installed inside the wheel, resulting in a simple structure, high cost-effectiveness, strong part interchangeability, and easy procurement.

- Adjusting the crane wheel when it bites the rail or derails is not convenient.

- Replacing and disassembling the hoist wheel can be quite troublesome.

Applications:

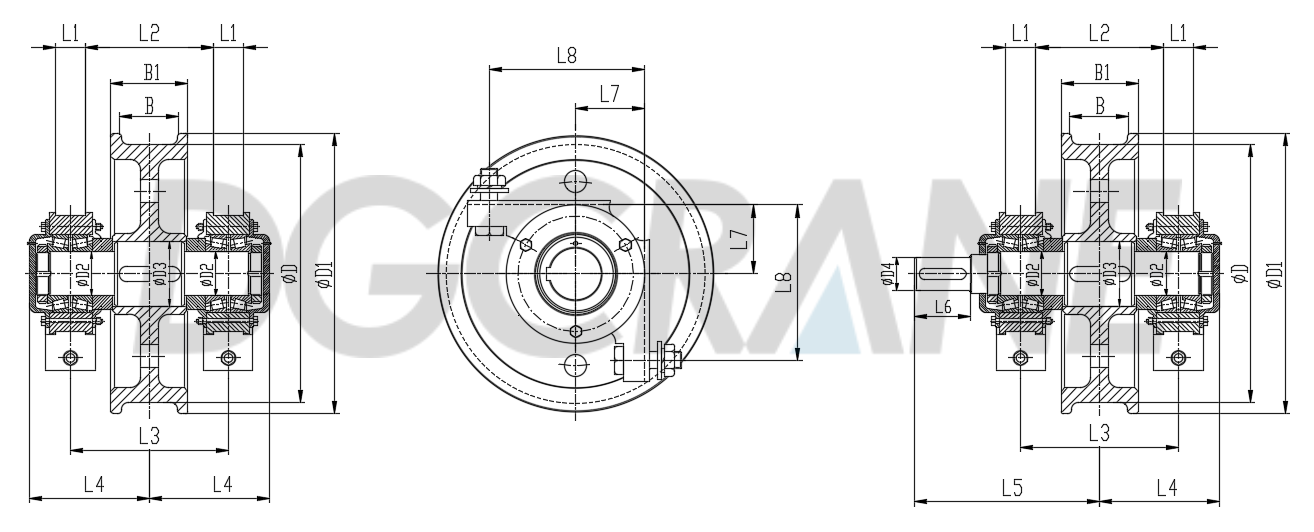

L Block Crane Wheel Assembly

Parameters:

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 50 | 230 | 280 | 230 | 400 | 105 | 140 | 310 | 271~293 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 264~286 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 80~150 | 130~210 | 50 | 230 | 280 | 230 | 415 | 130 | 140 | 310 | 316~381 | |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 306~381 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 80 | 235 | 315 | 260 | 455 | 130 | 160 | 350 | 502~542 |

| Passive crane wheels ø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 80 | 235 | 315 | 260 | / | / | 160 | 350 | 489~534 |

| Active crane wheels ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 90 | 275 | 365 | 300 | 500 | 130 | 190 | 410 | 742~823 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 90 | 275 | 365 | 300 | / | / | 190 | 410 | 729~810 |

Features:

- The L block crane wheel assembly typically features an angular bearing housing structure, making it suitable for heavy loads and frequent operating conditions.

- Installation errors in the wheel set can be manually adjusted and compensated for, ensuring assembly precision.

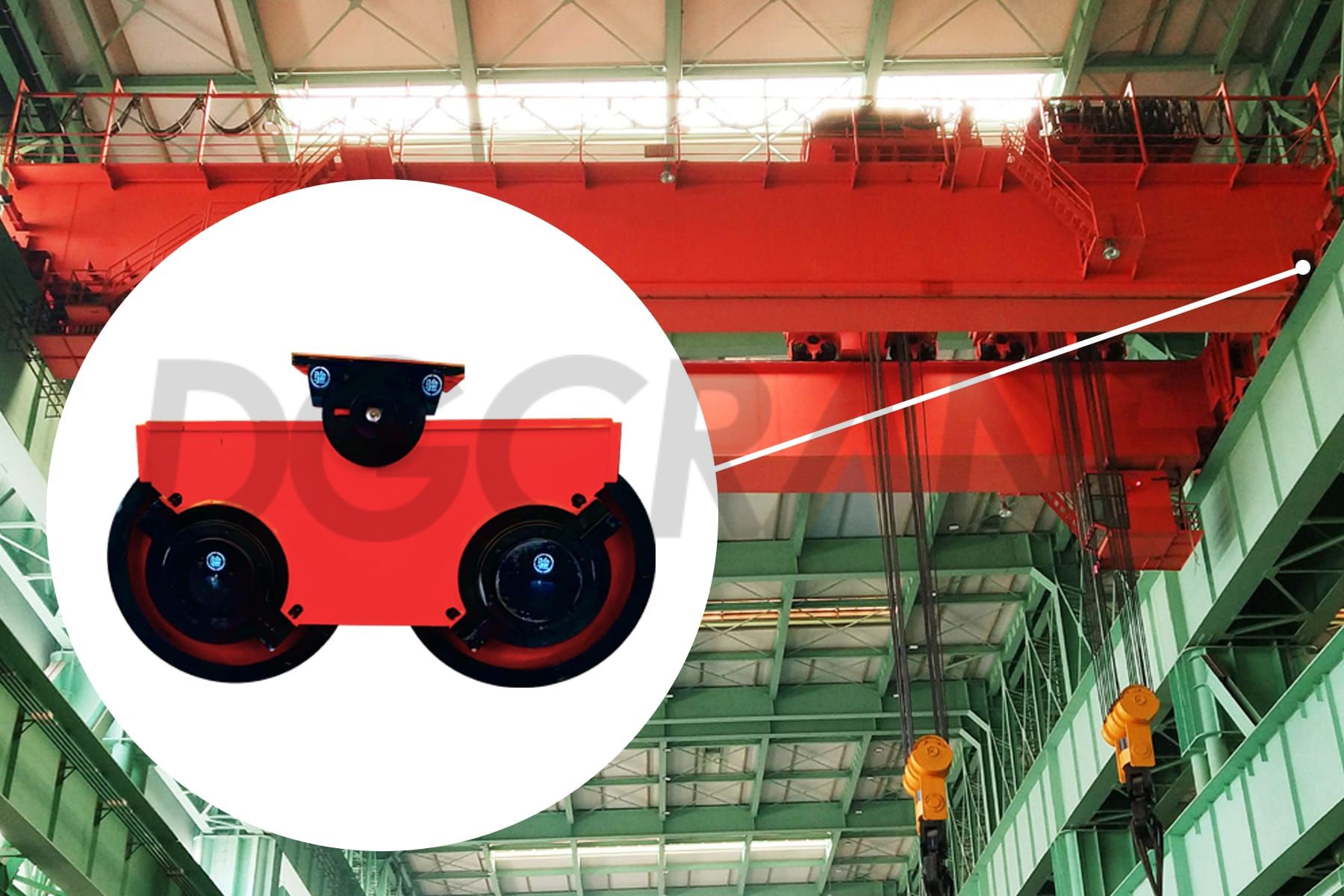

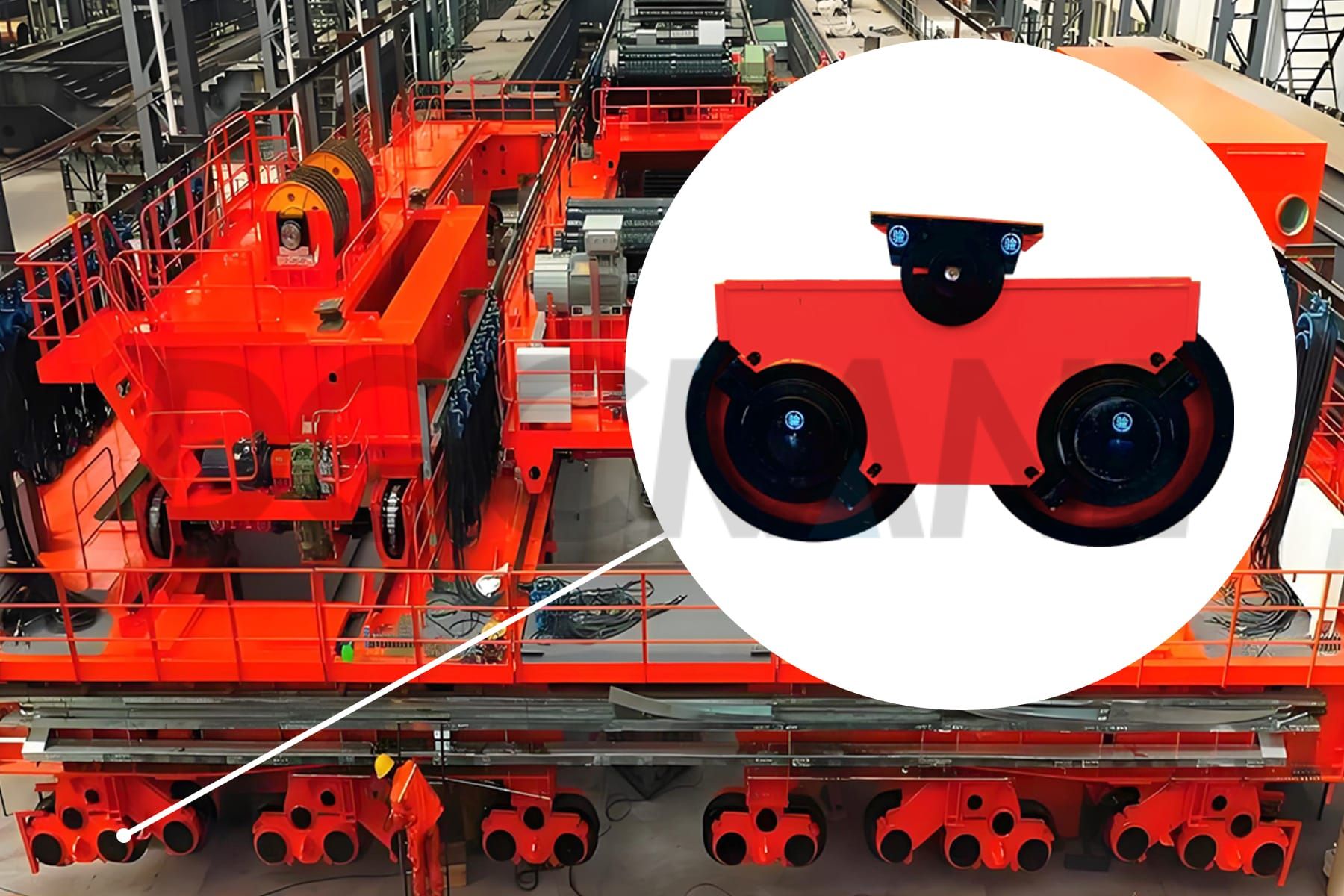

Applications:

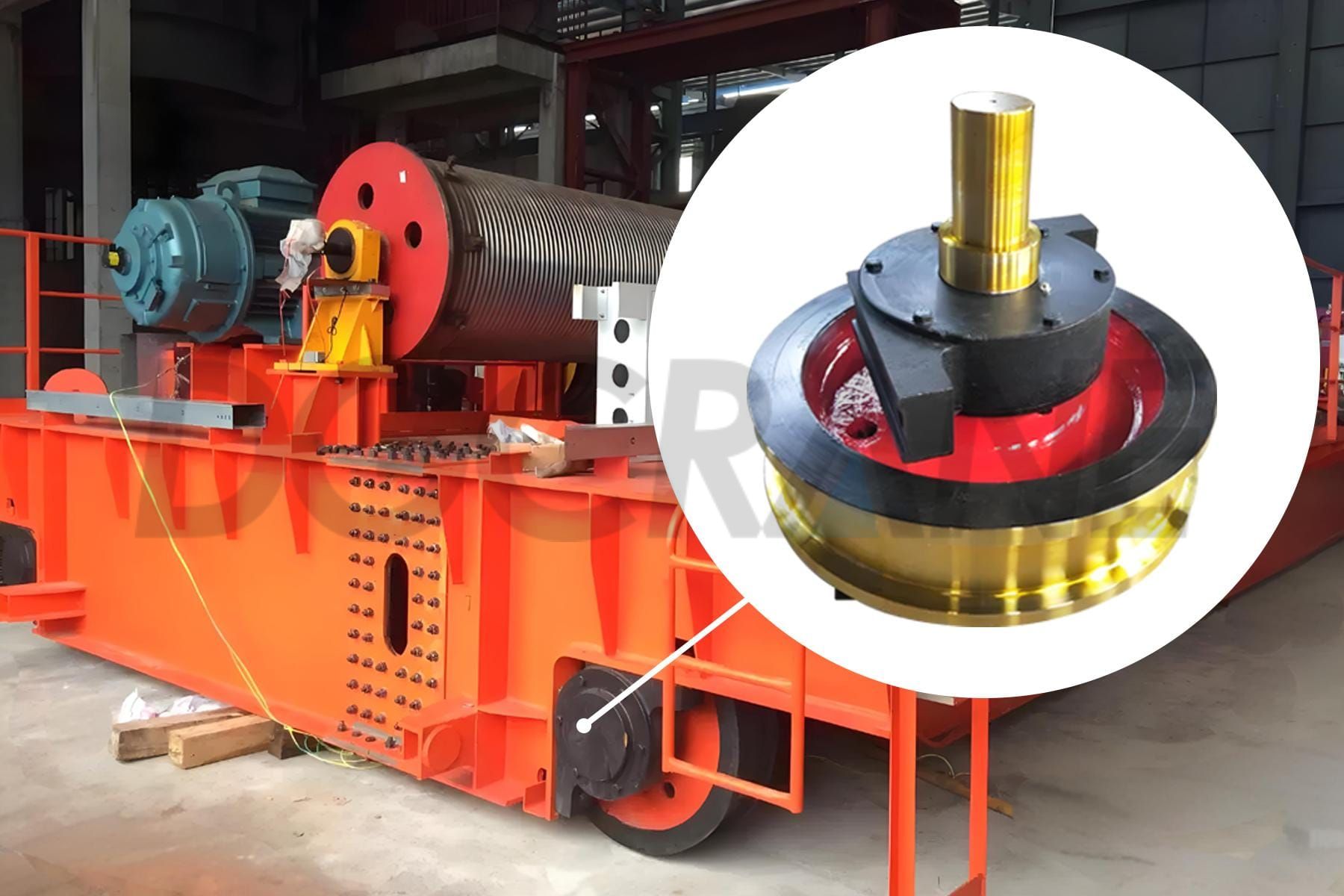

Cases:

4 Sets Crane Wheel Assemblies Delivered to Poland

- Size : Ø1000 x210 mm

- Crane wheel material:42CrMo

- Bearing brand: SKF Brand

- Crane wheel tread surface hardness: 45-50 HRC

- Depth:6-8 mm

- Surface hardness: HB220-260

4 sets of Ø1000x210mm Forged Wheel Assembly For Sale to Poland

- Wheel material: Forged 42Crmo;

- Shaft material: Forged 42Crmo

- Roller bearing Øi200-Øe310-109 cod. 24040 CC_W33

- Brand of bearing: SKF

- Processing technology: Forged

- Surface hardness: 45-50 HRC (deep penetration 6-8 mm)

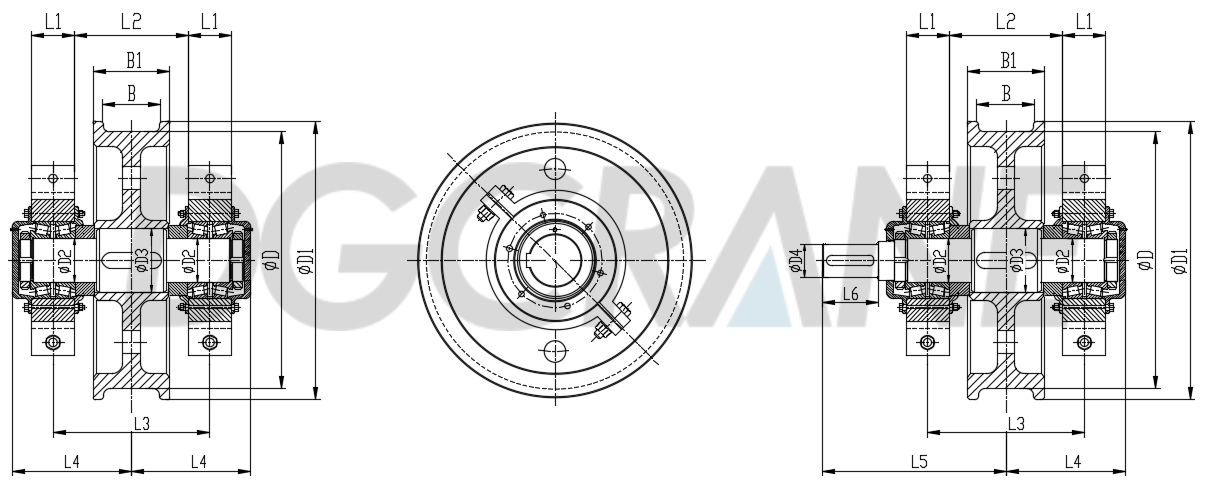

45°Split Bearing Box Crane Wheel Assembly

Parameters:

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 100 | 180 | 280 | 230 | 400 | 105 | 276~298 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 100 | 180 | 280 | 230 | / | / | 269~291 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 85 | 80~150 | 130~210 | 100 | 180 | 280 | 230 | 415 | 130 | 321~386 |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 100 | 180 | 280 | 230 | / | / | 311~386 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 120 | 195 | 315 | 260 | 455 | 130 | 507~547 |

| Passive crane wheelsø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 120 | 195 | 315 | 260 | / | / | 494~539 |

| Active crane wheel ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 140 | 225 | 365 | 300 | 500 | 130 | 747~828 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 140 | 225 | 365 | 300 | / | / | 734~815 |

Features:

- The bearing housing is designed with a 45-degree split, effectively reducing the contact stress between the wheel and the rail, thereby extending the wheel’s service life.

- The 45-degree split design ensures a more even stress distribution across the wheel, reducing local stress concentrations and enhancing the wheel’s durability and stability.

- This design allows stable operation in various complex conditions, including high temperatures, high humidity, and dusty environments.

- The 45-degree split design also makes the wheel easier to disassemble and replace, reducing maintenance time and costs.

Applications:

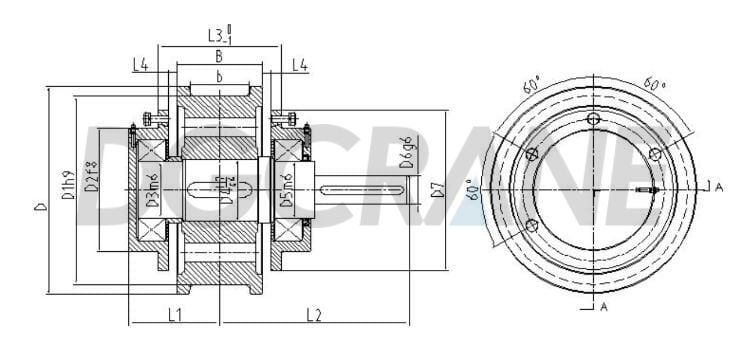

Round Bearing Box Crane Wheel Assembly (European Type)

Parameters:

| Item | D | D1 | D2 | D3 | D4 | D5 | D6 | D7 | L1 | L2 | L3 | L4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 230 | 200 | 120 | 50 | 55 | 50 | 40 | 180 | 101 | 195 | 136 | 12 |

| 250 | 280 | 250 | 150 | 60 | 65 | 60 | 40 | 210 | 120 | 235 | 174 | 12 |

| 315 | 355 | 315 | 180 | 70 | 75 | 70 | 45 | 250 | 145 | 237 | 200 | 15 |

| 400 | 440 | 400 | 260 | 120 | 130 | 120 | 60 | 340 | 192 | 408 | 260 | 22 |

Features:

- The round bearing housing has a compact structure that evenly distributes the load, reducing localized stress concentration.

- The bearing housing typically contains high-quality self-aligning roller bearings, which reduce operational friction and improve running smoothness.

- The flexible design is suitable for various installation methods, making it convenient to assemble with different types of lifting equipment.

- The bearing housing usually comes with standardized mounting holes, providing strong versatility and ease of installation and maintenance.

Applications:

Cases:

6 Pcs of Ø400x140mm Forged Wheel Exported to Thailand

Wheel material: Forged 42Crmo;

Surface hardness: 50-56 HRC

Weight: 340 kg/pcs

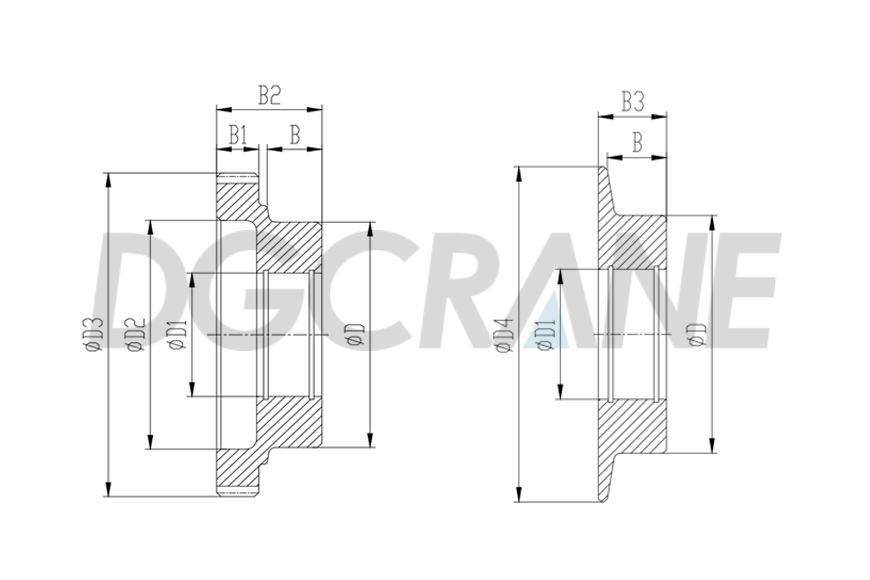

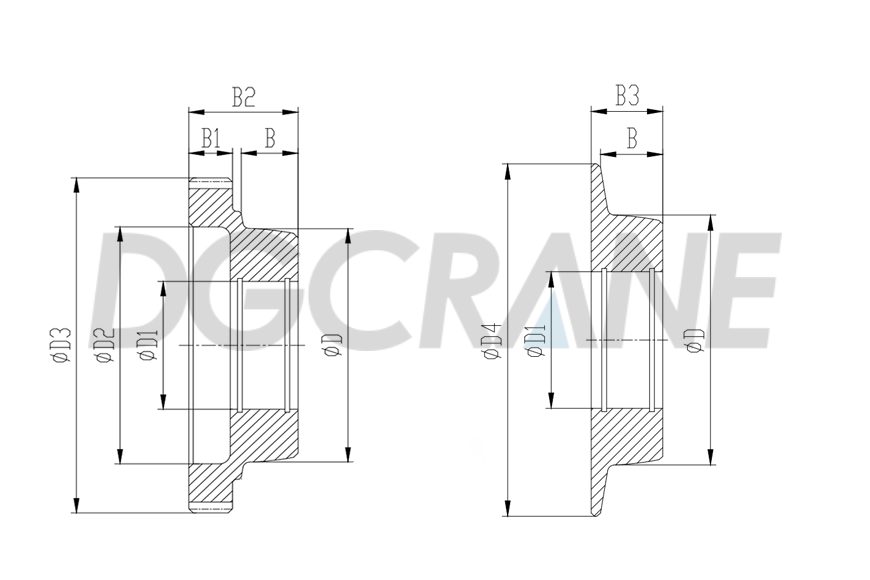

Hoist Trolley Wheel Sets (cylindrical tread)

Parameters:

| Model | øD1 | øD2 | øD3 | øD4 | øD | B | B1 | B2 | B3 |

|---|---|---|---|---|---|---|---|---|---|

| ø114 | 62 | 115 | 163 | 160 | 114 | 26 | 20 | 50 | 33 |

| ø134 | 100 | 155 | 181 | 155 | 134 | 30 | 22 | 57 | 40 |

| ø154 | 110 | 165 | 201 | 180 | 154 | 37 | 28 | 70 | 45 |

| ø164 | 120 | 165 | 208 | 200 | 164 | 39 | 28 | 72 | 47 |

Features:

- The design features a cylindrical tread, commonly used in conjunction with H-beams, box-type load-bearing beams, and other structures with flat bottom surfaces.

- The cylindrical tread design effectively reduces the contact stress between the wheel and the track, enhancing the fatigue resistance of the metal components.

- The wheel surface is treated with a quenching heat treatment process to further increase the load-bearing capacity of the wheel set.

Application:

Hoist Trolley Wheel Sets(conical tread)

Parameters:

| Model | øD1 | øD2 | øD3 | øD4 | øD | B | B1 | B2 | B3 |

|---|---|---|---|---|---|---|---|---|---|

| ø114 | 62 | 115 | 163 | 160 | 114 | 26 | 20 | 50 | 33 |

| ø134 | 100 | 155 | 181 | 155 | 134 | 30 | 22 | 57 | 40 |

| ø154 | 110 | 165 | 201 | 180 | 154 | 37 | 28 | 70 | 45 |

| ø164 | 120 | 165 | 208 | 200 | 164 | 39 | 28 | 72 | 47 |

Features:

- The design features a conical tread, suitable for use with I-beams, welded box beams with I-beam flanges, and other load-bearing components with a certain degree of slope on the lower flange.

- The wheel tread has a large contact area with the track flange, resulting in a low static wheel pressure concentration and strong load-bearing capacity.

- The working surface of the wheel is treated with a quenching heat treatment process, increasing the wheel’s hardness and wear resistance.

Application:

DGCRANE has had professional export crane wheels for 13 years, for you to customize the most suitable crane and transportation solutions, provide installation and maintenance services, and support product third-party testing.