Crane Parts

The excellent working of the overhead crane cannot be reached without coordination of overhead crane parts. After a long period of working time, the crane may appear some obsolescence, strain and wearout. In order to recover the high productivity, new components are essential. As an excellent crane parts supplier, our company always have the ability to provide high quality crane parts that not just match the overhead crane from our company but also suitable for products from other factory. The component is the guarantee to the high efficiency. There are three main catagories of crane components, welded steel structure, electric parts, mechanical parts. Because of the strong production capability and stable quality of our mechanical parts, our crane wheel, crane hook, rope drum are not only used in ourselves crane, but also applied in some other famous crane manufacturer. Give us the detail parameter of your cranes, hoists and the overhead crane parts you need, the more detailed the better, our designer will make the best solution for you with those parameters. Here comes a brief introduction of our main overhead crane parts:

Here comes a brief introduction of our main overhead crane parts:

Crane wheel

- Types – Casting or forging

- Heat treatment – quenching and tempering

- Diameter – available from 150mm to 900mm (6” to 36”)

- Material – according customer requirments

Crane rope drum

- Capability – strong production capability, available 0.5 to 500 tons

- Material – carbon steel and alloy steel and custom required material

- Heat treatment – quenched and tempered

- Standards – DIN standard crane hook is available

Crane hook

- Two kinds of forming methods: Casting iron rope drum, Steel plate rope drum.

- Drum diameter up to 1000mm (Steel plate rope drum)

- Surface hardness up to 60 HRC

Rich Industrial Experiences

We can provide you with various optional functions according to the special lifting needs in your industry, such as electronic anti-sway, remote monitoring, lifting synchronization and other functions. These are just a part of them.

Product Design Specifically for Export

Crane and Plant Integration Solutions Are Available

We don't just have cranes and other lifting products, we also offer a one-stop shop for custom steel buildings.

Adaptation to Special Plant Environments

We can meet the needs of factory environ-ments from -30 to 50 degrees Celsius, or for cranes with explosion-proof requirements.

Customized Voltage Supply

We can customize the generator to meet the different voltage requirements around the world, whether the voltage in your country is 100V~130V or 220~240V. Alternatively, generators are available.

Adequate Accessories

We are well equipped with spare parts that not only compress the production cycle and improve productivity, but also enable timely response in after-sales maintenance.

Flexible Procurement Programmes

- Transport Costs

- Cross Girder

- Other Parts

- Equipments Costs

- Cross Girder

- Other Parts

Complete plane

Component plane

Transport Cost Analysis

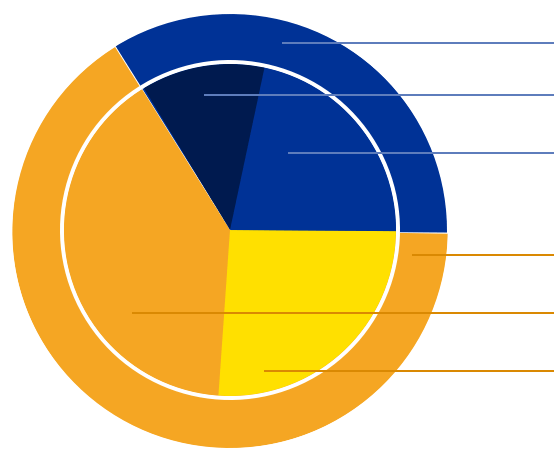

As shown in the Overhead Crane Costs Pie Chart (left), transport costs account for a significant portion of expenses, with the cross girder being the primary contributor. By addressing this cost driver, we offer two tailored solutions: Complete Crane and Component Crane packages.

Complete Overhead Crane Package

- Full System Delivery: Includes pre-assembled trolley, cross girder, end trucks, electrification systems, and all necessary components.

- Factory-Tested Reliability: Fully assembled and rigorously tested in our facility to ensure operational readiness.

- Easy Installation: Disassembled for shipping, then quickly reinstalled on-site with minimal effort.

- Best For: Clients prioritizing convenience, time savings, and hassle-free deployment.

Component Overhead Crane Package

- Exclusions: Cross girder (to be sourced locally by the client).

- Key Benefits:

- Reduced Transport Costs: Eliminate bulky cross girder shipping expenses.

- Local Flexibility: We provide detailed engineering drawings, 3D models, and step-by-step guidance for local cross girder fabrication.

- Best For: Cost-conscious clients with access to local steel resources or fabrication capabilities.

Application Cases

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!