Overhead Crane Cables: Reliable, Durable, and Cost-Effective Solutions for Safe Power Transmission

Overhead crane cables are vital for powering, controlling, and signaling crane systems, ensuring efficient and safe operations. They are broadly divided into four types: Festoon Cables for flexible motion, Chain Cables for heavy-duty lifting, Drum Reeling Cables for reeling applications, and Pendant Cables for precise control. Each type is designed to meet specific operational needs, providing reliability and durability in demanding industrial environments.

Festoon Cables

Festoon Round Cables

Designed for harsh environments, these cables are made with imported specialty materials and unique manufacturing processes. They feature flexibility, wear resistance, oil resistance, weather resistance, acid-alkali resistance, tensile strength, UV protection, and optional flame retardancy.

Product Structure

- Conductor: Multi-strand, tinned oxygen-free copper wire, compliant with VDE0295 CLASS 6 standards

- Insulation: High-strength composite materials

- Sheath: Premium PUR (Polyurethane)

Technical Parameters

- Voltage: 0.6/1KV

- Test Voltage: 3.5KV/5min (AC)

- Fixed Installation: 5x Cable outer diameter

- Flexible Installation: 6-10x Cable outer diameter

- Operating Temperature: -15°C to 70°C

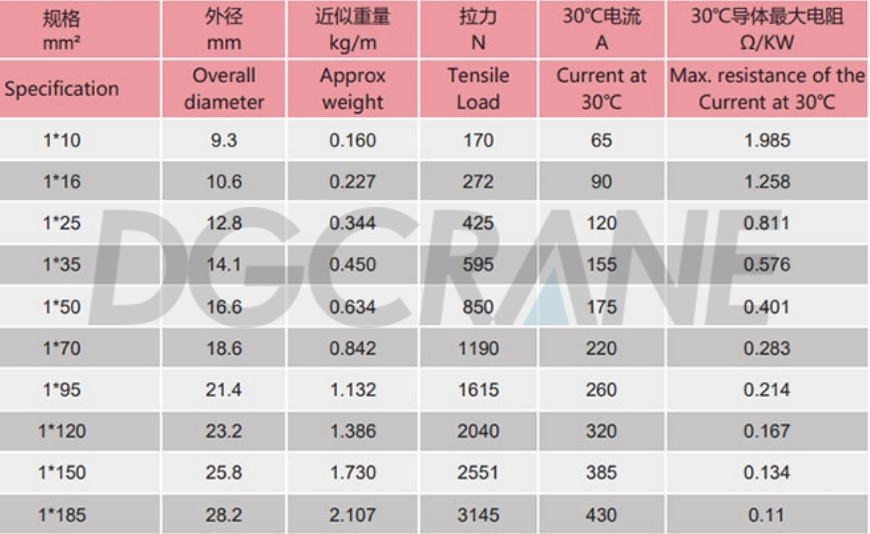

Specifications

Application Scenarios

Flat Festoon Cables

Flat festoon cables are suitable for use in festoon systems for lifting and long-stroke material handling equipment, such as overhead cranes, coal yard tippers, and metallurgical hoists. The cables are suspended and move back and forth, bending as they follow the festoon system. They exhibit flexibility, wear resistance, oil resistance, weather resistance, acid-alkali resistance, tensile strength, UV protection, and optional flame retardancy.

Product Structure

- Conductor: VDE0295 CLASS 6

- Insulation: High-strength composite materials

- Sheath: Premium PUR

Technical Parameters

- Voltage: 0.6/1KV

- Test Voltage: 3.5KV/5min (AC)

- Fixed Installation: 5x Cable outer diameter

- Flexible Installation: 6-10x Cable outer diameter

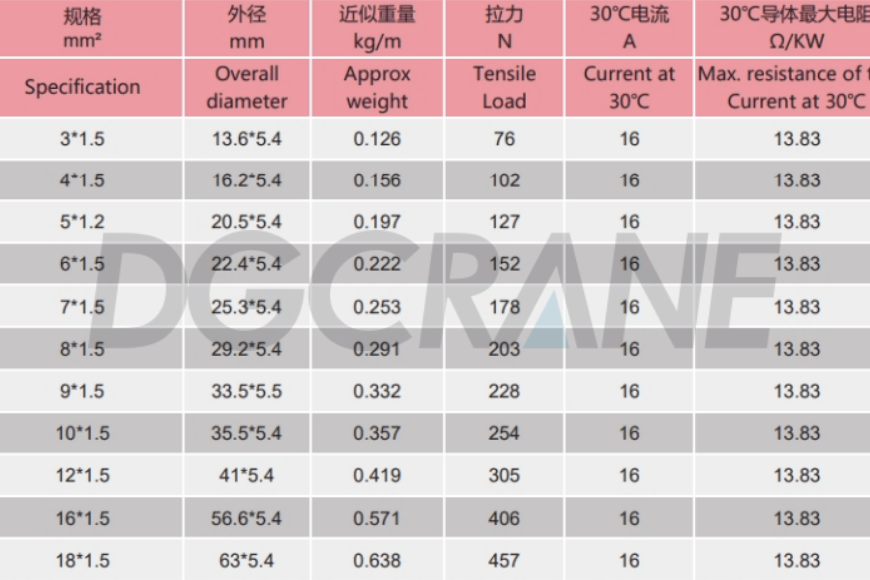

Specifications

Application Scenarios

Chain Cables

Chain cables are designed for use inside drag chain boxes, hence the name. These high-flex cables move, bend, and are continuously dragged and rubbed by the drag chain during operation. The drag chain resembles a tank’s track, which is why chain cables are sometimes referred to as “tank chain cables.” These cables are protected by the drag chain, preventing tangling, wear, pull-out, and scattering, thereby extending their service life.

Features

- Flexibility: Chain cables need good bending resistance to withstand frequent bending motions, which can cause breakage without it.

- Drag Resistance: These cables are dragged by the chain box during operation, requiring materials that can resist being easily pulled apart. The conductor and sheath materials are selected for their drag resistance.

- Wear Resistance: Chain cables constantly rub against the drag chain, making wear resistance critical. Standard flexible cables cannot be used for this purpose due to insufficient wear resistance, as their sheaths would wear out too quickly.

- Other Features: Chain cables are used in various types of equipment and operating environments. Different environments require different performance characteristics. For example, cables used in northern winters must have low-temperature resistance, those used in steel mills need high-temperature resistance, and others may need oil resistance, waterproofing, acid-alkali resistance, and corrosion resistance.

Application Scenarios

Drum Reeling Cables

Drum Flat Cables

These cables are characterized by high wear resistance, high strength, excellent flexibility, tear resistance, waterproof properties, bending resistance, fold resistance, oil resistance, cold resistance (-40°C to 80°C), UV protection, and flame retardancy. Their service life in high-frequency use is at least three times longer than standard rubber flat cables.

Product Structure

- Conductor: Multi-strand ultra-fine tinned oxygen-free copper wire, compliant with VDE0295 CLASS 6 standards

- Insulation: Special mixed PVC insulation material

- Core Wire Color: Numbered or color-coded (customizable per customer requirements)

- Inner Sheath: Special high-strength composite material

- Outer Sheath: Polyurethane (PUR)

- Outer Sheath Colors: Grey, black, orange (custom colors available upon request)

Technical Parameters

- Rated Voltage: ≥0.5mm: 300/500V, <0.5mm: 300/300V

- Test Voltage: 2500V

- Temperature Range:

- Fixed Installation: -40°C to +105°C

- Flexible Installation: -40°C to +105°C

- Minimum Bending Radius:

- Fixed Installation: 5x Cable outer diameter

- Flexible Installation: 7.5x Cable outer diameter

Application Scenarios

Drum Round Cables

Drum round cables feature reinforced cores and are suitable for use in mobile equipment subject to high mechanical stresses, such as fast-moving container cranes, hoisting equipment, large mobile equipment, excavators, and both surface and underground mining operations. These cables offer long service lives and stable quality, with a polyurethane sheath that enhances wear resistance and durability in harsh environments.

Product Structure

- Conductor: Ultra-fine stranded copper wire (tinned optional), compliant with IEC60228 CLASS 6

- Insulation: High-quality modified PVC

- Grounding Wire: Optional, depending on cable structure, 3+3 configuration

- Inner Sheath: Mixed modified PVC

- Outer Sheath: Polyurethane (PUR)

Technical Parameters

- Voltage: 0.6/1KV

- Test Voltage: 3500V/5min (AC)

- Bending Radius:

- Fixed Installation: 5x Cable outer diameter

- Flexible Installation: 10x Cable outer diameter

- Temperature Range:

- Fixed Installation: -40°C to +90°C

- Flexible Installation: -35°C to +90°C

- Flame Retardancy: Compliant with IEC60332-1

- Chemical Resistance: Excellent resistance to acids, alkalis, solvents, and various hydraulic oils

- Weather Resistance: UV resistance, excellent performance under sunlight, suitable for outdoor use

Application Scenarios

Pendant Cables

Applications

Double steel wire crane control cables are widely used in lifting, transportation, machinery, electrical, mining, metallurgy, port, and dock industries for crane control purposes. These control cables are typically used for working voltages below 450/750V and in environments with temperatures ranging from -55°C to 70°C.

Product Structure

- Conductor: Annealed, tensile-resistant oxygen-free copper

- Reinforcement: High-strength galvanized steel wires (two strands)

- Insulation Sheath: Wear-resistant nitrile rubber mixed material specially designed for flat cables

- Colors: Black, yellow (custom colors available upon request)

- Filling: Jute rope

- Wrapping: Non-woven fabric

How to maintain and care for crane cables?

Regularly inspect the connection points:

The connection points of crane cables are vulnerable to mechanical damage and corrosion. Regularly check these connections for any looseness or damage. If any issues are found, take immediate repair actions.

Keep the cables clean and dry:

Cranes often operate in environments exposed to dust, moisture, and other factors that can affect the cables. To maintain optimal insulation performance, regularly clean the cable surfaces and ensure proper moisture protection.

Be mindful of load-bearing and transportation:

During lifting and transportation, pay attention to the cable's load-bearing capacity. Avoid overstretching the cables or exposing them to severe impacts, as this can damage the conductors and insulation materials.

How to choose the right crane cable based on the operating environment?

The operating environment of the crane is a critical factor in selecting the appropriate cable. Different environments impose varying requirements on the cables, so it is essential to choose a cable suited to the specific conditions.

For questions related to selecting or purchasing crane cables, please contact us. Our professional team is dedicated to providing you with the best service!