Manual Overhead Cranes

A manual overhead crane is a type of lifting equipment that is designed for material handling within various industrial environments, utilizing manual force for operation. Unlike their electrically powered counterparts, these cranes are operated by hand, typically through the use of chains or manual hoists.

The main advantage of manual overhead cranes lies in their operational simplicity and reduced need for electrical components, which can lower maintenance costs and eliminate the reliance on electrical power. This makes them particularly useful in environments where electrical power is unavailable, unreliable, or where explosive atmospheres may exist, making electric equipment unsuitable.

Different Types of Manual Overhead Crane

SL Manual Single Girder Overhead Cranes

Feature a single beam that spans the width of the workspace, with a manual hoist running along the bottom flange. This straightforward design is suitable for a wide range of lifting needs, offering a balance between performance and cost-effectiveness. The single girder design simplifies installation and maintenance, making it a go-to option for many small to medium-sized applications.

| Series Model | Capacity(t) | Span(m) | Lifting Height(m) | Work duty | Crane Travelling Speed(m/min) | Price($) |

|---|---|---|---|---|---|---|

| SL | 1 | 5~14 | 3~10 | A1-A3 | 6.18 | 1004~1633 |

| SL | 2 | 5~14 | 3~10 | A1-A3 | 6.18 | 1067~1681 |

| SL | 3 | 5~14 | 3~10 | A1-A3 | 6.18 | 1117~1760 |

| SL | 5 | 5~14 | 3~10 | A1-A3 | 4.25 | 1286~2143 |

| SL | 10 | 5~14 | 3~10 | A1-A3 | 2.98 | 1686~2686 |

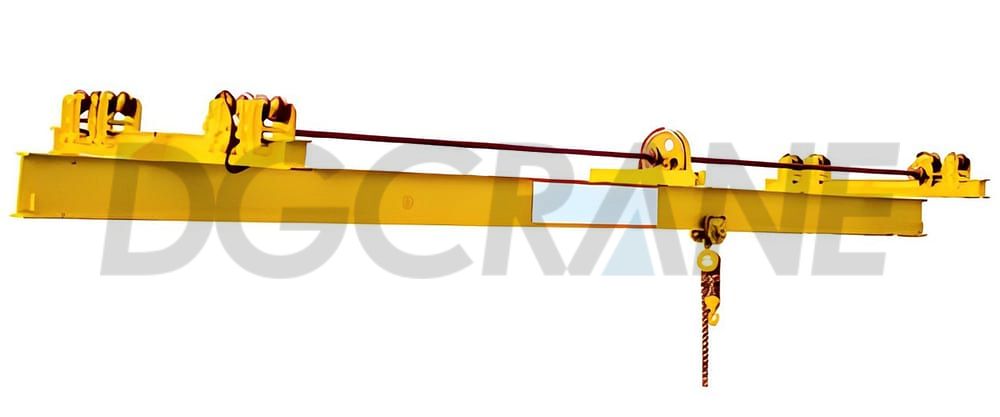

SLX Manual Underslung Single Girder Overhead Cranes

Unlike the standard overhead mounting, these cranes are mounted directly onto the lower flanges of the existing roof structure, making them ideal for spaces with limited headroom or where maintaining floor space is critical. The underslung configuration allows these cranes to operate in facilities with complex layouts or where additional overhead cranes are required without significant structural modifications.

| Series Model | Capacity(t) | Span(m) | Lifting Height(m) | Work duty | Crane Travelling Speed(m/min) | Price($) |

|---|---|---|---|---|---|---|

| SLX | 1 | 5~14 | 3~10 | A1-A3 | 5.2 | 953~1551 |

| SLX | 2 | 5~14 | 3~10 | A1-A3 | 5.2 | 1013~1596 |

| SLX | 3 | 5~14 | 3~10 | A1-A3 | 5.2 | 1061~1672 |

| SLX | 5 | 5~14 | 3~10 | A1-A3 | 4.3 | 1221~2035 |

| SLX | 10 | 5~14 | 3~10 | A1-A3 | 4.3 | 1601~2551 |

Characteristics of Manual Overhead Cranes

- Simple Design: Manual overhead cranes feature a straightforward design, typically comprising a single beam spanning the workspace, with a manual hoist for lifting and moving loads.

- Cost-Effectiveness: Manual overhead cranes offer a cost-effective lifting solution, with lower initial investment and maintenance costs compared to automated or electric counterparts.

- Ease of Operation: Operating manual overhead cranes is relatively simple, requiring minimal training for operators. This simplicity enhances user efficiency and reduces the risk of errors.

- Safety: While manual overhead cranes require human operation, they eliminate the risks associated with electrical malfunctions or power outages, making them safer to use in certain environments.

- Space-Saving: Manual overhead cranes utilize overhead space efficiently, leaving the floor area clear for other operations. This space-saving feature is particularly beneficial in congested work environments.

- Durability: Constructed from robust materials, manual overhead cranes are built to withstand heavy-duty use and harsh working conditions, ensuring long-term reliability and performance.

- Portability: Some manual overhead cranes are designed to be portable, allowing for easy relocation to different work areas as needed.

- Accessibility: Manual overhead cranes can be installed in locations where access to power sources is limited or impractical, expanding their usability in various settings.

- Maintenance: With fewer complex components compared to automated systems, manual overhead cranes require less maintenance and are easier to service, minimizing downtime and operational disruptions.

Applications of Manual Overhead Cranes

Manual overhead cranes are characterized by their simple yet versatile design, offering cost-effective lifting solutions for a wide range of industries. With ease of operation, safety, space-saving capabilities, and durability, these cranes provide efficient and reliable performance in diverse environments. Additionally, their portability and accessibility make them ideal for locations with limited power sources or where frequent relocation is required. Low maintenance requirements further enhance their appeal, ensuring uninterrupted operations and maximum productivity. Manual overhead crane perfect for small to medium-sized workshops, maintenance departments, and assembly areas where electrical power is not necessary or preferred.

Maintenance of Pump Houses in Chemical Plants

In the pump houses of various tank areas such as liquefied petroleum gas, gasoline, aviation kerosene, diesel, waste oil, and fuel oil, where flammable and explosive environments prevail, any electrically operated equipment must be explosion-proof to prevent sparks or heat from triggering the explosion of hazardous substances. While electric explosion-proof cranes can meet safety requirements, their high cost forces many chemical enterprises to seek a balance between cost and safety.

In this regard, manual overhead cranes have a natural advantage because they rely entirely on manual operation, eliminating the risk of electric sparks or heat generation. This non-electrical characteristic makes manual bridge cranes an ideal lifting tool in high-risk environments such as chemical plant pump rooms.

At this point, manual bridge cranes, with their low cost and reliable safety features, have become a highly attractive alternative. Compared to electric explosion-proof cranes, the procurement and maintenance costs of manual overhead cranes are significantly reduced.

For budget-constrained chemical enterprises, manual bridge cranes provide an economically efficient solution, enabling companies to control costs to the maximum while ensuring operational safety. This cost-effective advantage, especially in large chemical plants requiring a large number of lifting equipment, can significantly reduce long-term operating costs.

Hydroelectric Power Plant Maintenance Workshop

In the construction process of small hydroelectric power stations, manual overhead cranes play a crucial role, especially in the installation and maintenance of turbine units in off-grid environments.

Small hydroelectric power stations are typically located in remote areas, which may lack stable power supply, especially during the initial construction phase. Manual bridge cranes can operate in completely non-electric environments, providing great convenience for the installation of turbine units and other large equipment. This characteristic makes manual overhead cranes an ideal equipment for the construction of hydroelectric power stations in remote areas.

Compared to electric cranes, manual bridge cranes are much simpler to operate and maintain, which is an important advantage for personnel working on small hydroelectric power station construction projects. It allows on-site workers to operate the crane with simple training, significantly reducing the reliance on professional operators while ensuring efficient and continuous equipment usage.

Installation and Maintenance of Coal Grinders in Thermal Power Plant Coal Bunkers

In the specific environment of coal bunkers within thermal power plants, the installation and maintenance of coal grinders for thermal power generating units demonstrate the unique advantages and importance of manual overhead cranes, especially in confined spaces with limited power installation space. These characteristics make manual overhead cranes indispensable equipment, particularly in older power plants where space requirements for modern large-scale mechanical equipment may not have been adequately considered during design. Manual bridge cranes, with their compact structure and flexible operation, are highly suitable for working in such space-constrained environments.

Compared to electric cranes, manual bridge cranes do not require complex power configurations, which is particularly important in situations where power installation space is limited. Coal grinders are critical equipment in thermal power plants, and their stable operation directly affects power generation efficiency and safety. During the installation or maintenance of coal grinders, even in the narrowest spaces, the safe and accurate positioning of components can be ensured. Additionally, the characteristic of manual operation makes it more user-friendly and intuitive for fine adjustments, reducing the safety risks associated with operational errors.

Manual bridge cranes are much simpler to operate and maintain, which is an important advantage for personnel working on small hydroelectric power station construction projects. It allows on-site workers to operate the crane with simple training, significantly reducing the reliance on professional operators while ensuring efficient and continuous equipment usage.

On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.