LDY Metallurgical Single Girder Overhead Cranes: Safe Molten Metal Lifting for Foundries and Steel Plants

The LDY metallurgical single girder overhead crane is a spatial transportation tool used in conjunction with a metallurgical electric hoist. Its primary function is to complete the displacement of heavy objects required in metallurgical production through an intermittent, cyclical working mode. This is achieved by lifting hooks or other lifting devices, which move loads quickly and efficiently. It is an essential tool and equipment for improving labor productivity in metallurgical and casting sites in modern industrial enterprises. The bottom of the crane's main beam is specially insulated and mainly used for lifting molten metal.

- Capacity: 2t-10t

- Span length: 18-36m

- Lifting height: 7m, 9m, 12m, etc.

- Work duty: A6

- Rated voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -10℃~+60℃, relative humidity ≤50%

- Crane control mode: Pendant control / Wireless remote control

Components

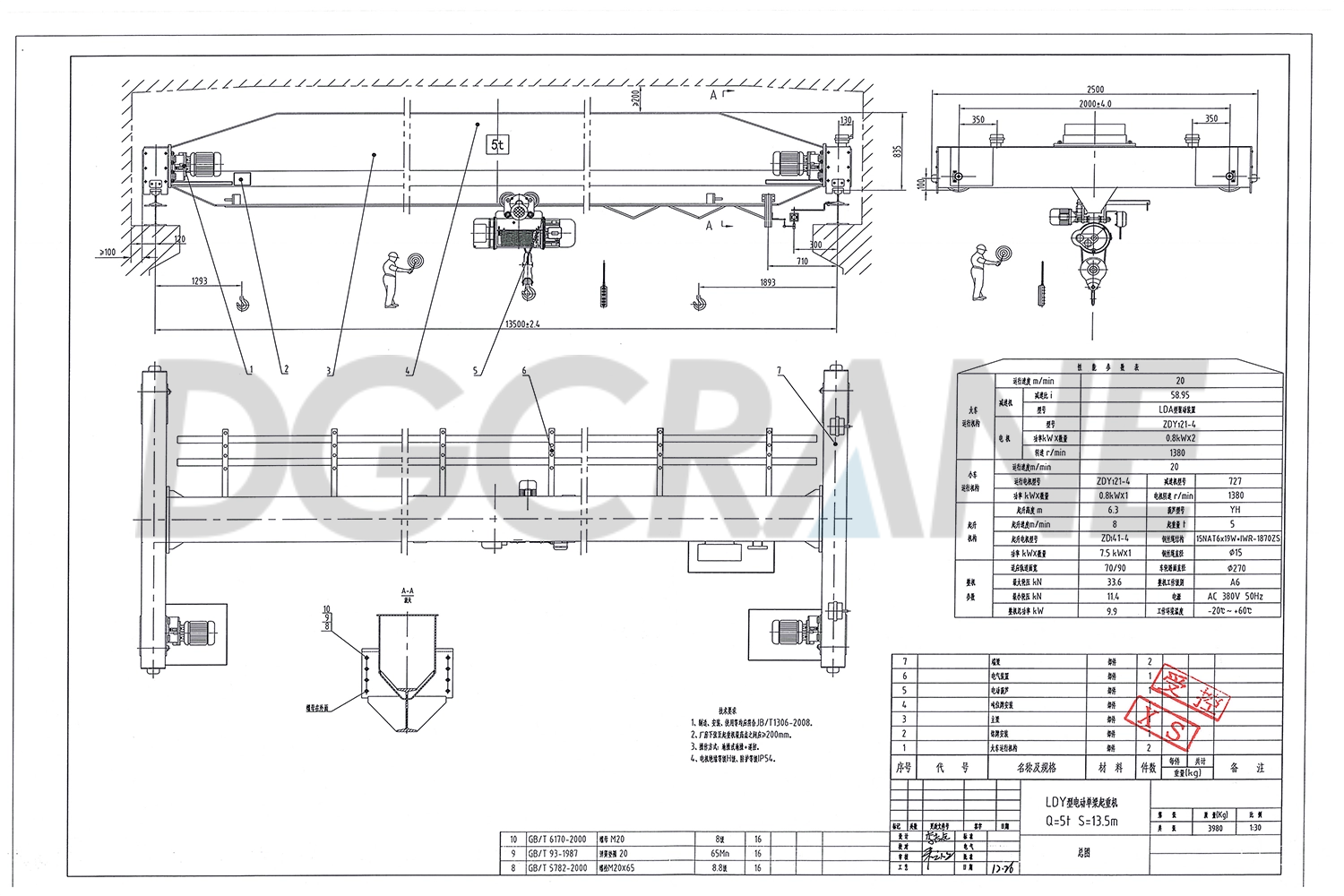

The LDY-type metallurgical single girder overhead crane is mainly composed of three parts: the bridge, the metallurgical electric hoist, and the electrical system.

Main Beam (Bridge Structure): The bottom of the main beam of the LDY-type metallurgical single girder overhead crane is specially insulated. The main beam is welded into a solid web beam using U-shaped channel steel and I-beam or a box-shaped beam using steel plates. The end beam is a box structure welded with U-shaped channel steel. The main and end beams are connected by a bolted anti-shear flange structure or a seating structure, which makes installation convenient and transportation and storage easier.

Lifting Mechanism: The LDY-type metallurgical single girder overhead crane is equipped with a lifting mechanism consisting of a metallurgical electric hoist. The hoist is equipped with three independent braking devices: a brake, a safety brake (i.e., a double-brake system), and an overload limiter. It can lift and move heavy loads along the main beam.

Electrical System: The lifting motor of the metallurgical electric hoist uses a conical rotor motor with a large starting torque to accommodate the frequent direct starts required in intermittent crane operations. To withstand ambient temperatures exceeding 40℃, the motor uses class H insulation and high-temperature resistant cables. The main circuit and control circuit have fewer electrical components, simplifying the wiring and making maintenance easy. Insulation and heat protection measures are applied externally to the motor and other electrical equipment.

Case

Steel Company Foundry Production Line Used for Lifting Molten Steel

Main Technical Parameters

- Lifting Capacity: 5t

- Span: 13.5m

- Lifting Height: 6.3m

- Travel Distance: 55m

- Control Methods: Remote control and wired handle operation

- Working Class: A6

- Electric Hoist Lifting Height: H = 6.3 meters; Working Class ≥ M6

- Power Supply: 3-phase, 50Hz, 380V

Technical Features

- The lifting mechanism is equipped with one support brake and one safety brake.

- It has a dual-limit function for upper limits. The first limit is a heavy hammer limit switch, and the second is the conventional limit switch for the electric hoist’s up-and-down power cut-off.

- Lifting Weight Protection Function:

- Equipped with a lifting weight limiter and a scale, featuring load setting and LCD display of the lifted weight.

- High-Temperature Insulation Protection:

- A thermal insulation plate is installed below the electric hoist drum to shield against the intense heat radiation from molten metal.

- Insulation Class:

- The insulation class for the lifting motor and running motor is H, and the lifting motor is equipped with an overheating protection device in the motor windings.

- High-strength, Heat-Resistant Steel Wire Rope:

- The wire rope is specifically designed for metallurgical environments, with high strength and resistance to high temperatures.

- Dual-Point, Dual-Speed Remote Control:

- Equipped with both remote control and wired handle control.

Specification

For more detailed specifications, please refer to DGCRANE’s catalog of LDY metallurgical single girder overhead cranes.

At DGCRANE, we offer professional, customized solutions with our LDY Metallurgical Single Girder Cranes, designed to meet the specific needs of your foundry or steel plant. Our cranes are carefully crafted to support safe and efficient molten metal handling. With a focus on safety and technical expertise, we aim to enhance your operational efficiency while maintaining high safety standards. Partner with DGCRANE for tailored lifting solutions that prioritize both productivity and safety in your unique environment.