Jib Cranes

When the spare room of your plant or factory is not sufficient to install a gantry or an overhead crane, a jib crane is the ideal solution. As one of fast growing jib crane manufacturers, we pay high attention on the quality and safety. The main idea to solve this question is to let the beam rotate instead of traveling along a track to cover the area in which the material need to move. If required, the beam of this kind crane can horizontal rotate for 360 degree. At most cases, the more area covered by the rotation of our crane, the better. But some special environments prefer to a limitation of the equipment’s rotation. In either case, our machine can meet the requirements. This kind cranes can rotate by manually or electrically control. You can choose the control mode base your actual situation. And, generally, it is suitable for use under the working strength of medium-load or light-load.Safe working load can up to about 10t. Because of the jib crane’s favorable structure, it can easily adapt to the customers specific requirements and can be installed in any position such as floors and walls .In order to save money and seek convenient, combined with our customers’ actual situation, our experienced designers can even mount the cranes on the existing columns or other crane’s beam.the advantages of jib crane

In general, jib crane is ideal for low-cost lifting within a plant.- Easy to install and relocate. Nearly can be installed in anyplace if needed.

- Because of the its good adaptability, it can adapt with your changing needs with a little modify.

- Some kinds of this special cranes require no floor space while others can maximize the lifting height. So, with them, the utility rate of space is unrivaled.

- The structure of this kind crane is small and flexible. It can work as a supplement for a gantry or overhead crane. By working together, the productivity of your workshop can ultimately increase to the maximum.

- If the material you need to move is light and small, launch a high-power overhead or gantry crane is a great waste. Under those circumstances, low-power crane hand goods more effectively.

our jib cranes’ unique features

Because of the accurate of the beam alignment, the beam and trolley are in better control. The unintended movements of beam and trolley can be minimized and so does the possibility of damages to the crane operaters and the equipment itself.- There is a great diversity of operation types from full manual to full powered. You can choose the most practical way for yourself according the special situation. Each installation type such as wall, column and freestanding mounting is available.

- The negative effects of off-center loading on jib crane’s quality is not being taken seriously by most jib crane designers. To eliminate off-center loading problems, we designe the slide the die set on the press bolster to make the highest load move towards the press centerline.

- We have advanced technology on getting the optimal highest hook position applied to low headroom jib cranes. And our wall mounted jib cranes can squeeze into the tightest plant, warehouse or other industrial space. So, the scope of available installation space is bigger and the utilization rate is higer.

- We add an emergency stop system to strength safety. If the operation staff encounter some emergency situation, we could start the emergency brake system to protection the related treasure.

- Most important of all, we always keep our customer’s safety in our mind!

Rich Industrial Experiences

We can provide you with various optional functions according to the special lifting needs in your industry, such as electronic anti-sway, remote monitoring, lifting synchronization and other functions. These are just a part of them.

Product Design Specifically for Export

Crane and Plant Integration Solutions Are Available

We don't just have cranes and other lifting products, we also offer a one-stop shop for custom steel buildings.

Adaptation to Special Plant Environments

We can meet the needs of factory environ-ments from -30 to 50 degrees Celsius, or for cranes with explosion-proof requirements.

Customized Voltage Supply

We can customize the generator to meet the different voltage requirements around the world, whether the voltage in your country is 100V~130V or 220~240V. Alternatively, generators are available.

Adequate Accessories

We are well equipped with spare parts that not only compress the production cycle and improve productivity, but also enable timely response in after-sales maintenance.

Flexible Procurement Programmes

- Transport Costs

- Cross Girder

- Other Parts

- Equipments Costs

- Cross Girder

- Other Parts

Complete plane

Component plane

Transport Cost Analysis

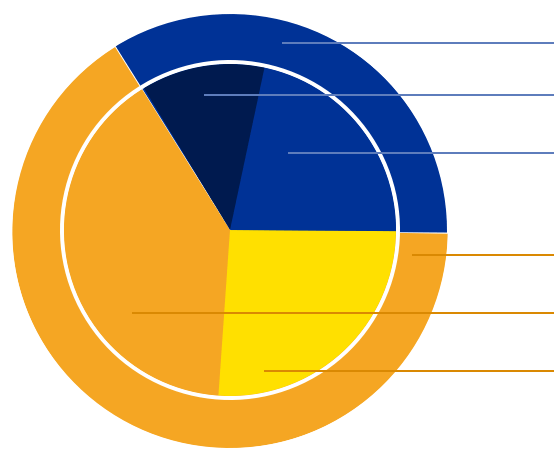

As shown in the Overhead Crane Costs Pie Chart (left), transport costs account for a significant portion of expenses, with the cross girder being the primary contributor. By addressing this cost driver, we offer two tailored solutions: Complete Crane and Component Crane packages.

Complete Overhead Crane Package

- Full System Delivery: Includes pre-assembled trolley, cross girder, end trucks, electrification systems, and all necessary components.

- Factory-Tested Reliability: Fully assembled and rigorously tested in our facility to ensure operational readiness.

- Easy Installation: Disassembled for shipping, then quickly reinstalled on-site with minimal effort.

- Best For: Clients prioritizing convenience, time savings, and hassle-free deployment.

Component Overhead Crane Package

- Exclusions: Cross girder (to be sourced locally by the client).

- Key Benefits:

- Reduced Transport Costs: Eliminate bulky cross girder shipping expenses.

- Local Flexibility: We provide detailed engineering drawings, 3D models, and step-by-step guidance for local cross girder fabrication.

- Best For: Cost-conscious clients with access to local steel resources or fabrication capabilities.

Application Cases

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!