Harbour Portal Crane

Harbour portal cranes are widely used in ports, wharves, yards and other places to complete the loading, unloading and transferring operations of ships and vehicle loads with grabs or hooks. The design, manufacture and inspection are carried out in accordance with DIN, FEM, IEC, AWS, GB and other advanced standards at home and abroad, as well as the latest national standards.

The electrical drive adopts all-digital AC frequency conversion, PLC control speed regulation unique technology, flexible control and high precision.

Port portal cranes are categorized into single boom and four-link types according to the form of jib structure. Single boom portal cranes have simple structure, large lifting capacity and light weight. Four-link portal cranes use a combination of jib systems to realize the luffing process of horizontal movement of goods, with a small horizontal drop, smooth luffing, low power consumption. Both types of gantry cranes can meet the requirements of general cargo, bulk cargo and container loading and unloading operations, with a wide range of applications, high operating efficiency, stable operation of the machine and other characteristics.

Four link portal harbour crane

Product Features

- Provide a variety of structural forms of grab rope stabilizing device, good rope stabilizing effect, significantly inhibit the swing of the spreader;

- Dual-machine synergistic operation technology, with high control precision and good synergistic effect;

- The hinge point of the boom moves upward, realizing the wire rope winding, prolonging the service life of the wire rope and facilitating the maintenance;

- Container spreader automatic slewing following technology, improve operation efficiency and safety;

- Vector frequency conversion and power feedback technology, energy saving and environmental protection;

- Automatic fault detection and data real-time display technology, safe and reliable;

- Provide a variety of operating modes – manual semi-automatic automation remote operation, advanced technology, stable performance;

- Core technologies such as operation, slewing positioning, intelligent following of spreader trajectory, intelligent safety protection, etc;

- Complete with various safety measures such as high wind alarm and safety dynamic scanning.

| Main Technical Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Basic parameters | Rated lifting capacity | Hook(t) | 10 | 80 | ||||

| Grab(t) | 10 | 16 | 25 | 40 | 60 | 40 | ||

| Lifting height | Above the rail surface(m) | 20 | 25 | 25 | 28 | 30 | 35 | |

| Below the rail surface(m) | 10 | 20 | ||||||

| Max. working range(m) | 30 | 45 | ||||||

| Min. working range(m) | 8.5 | 12 | ||||||

| Slewing radius of tail(m) | 6.5 | 9.5 | ||||||

| Rail gauge(m) | 10.5/12 | 12/14/16 | ||||||

| Base distance(m) | 10.5/12 | 12/14/16 | ||||||

| Speed parameters | Lifting speed | Full load | 40 | 30 | ||||

| No load | 60 | 50 | ||||||

| Luffing speed(m/min) | 40 | 30 | ||||||

| Slewing speed(r/min) | 1/1.2/1.5 | 0.8/1 | ||||||

| Crane traveling speed(m/min) | 25/30 | 25/30 | ||||||

| Number of Wheels | 16/20 | 40 | ||||||

| Max. wheel load | 250 | 300 | ||||||

| Rail Type | QU80 | QU100 | ||||||

| Power Supply | Three Phase AC 380V 50Hz | |||||||

| Installed capacity | kw | 350 | ||||||

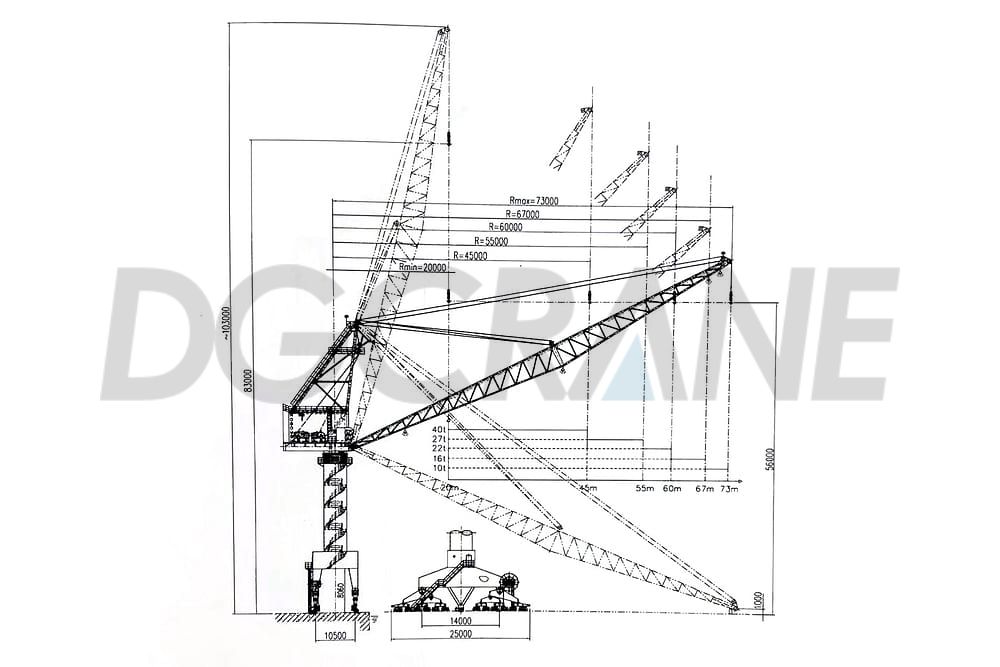

Single Boom Portal crane

Product Features

- Single boom gantry cranes have simple structure, large lifting capacity and light weight.

- A variety of structural forms of grab rope stabilizing device, rope stabilization effect is good, significantly inhibit the swing of the spreader;

- Dual-machine cooperative operation technology, high control precision, good cooperative effect;

- The hinge point of the boom moves upward, realizing the wire rope winding, prolonging the service life of the wire rope and facilitating the maintenance;

- Container spreader automatic slewing following technology, improve operation efficiency and safety;

- Electricity feedback technology, energy saving and environmental protection;

- Gale alarm, safety dynamic scanning and other various safety measures are complete.

| product specification | 4073 | ||||||

|---|---|---|---|---|---|---|---|

| Group Classification of complete machines | A4 | ||||||

| Elevating capacity | Lifting capacity | t | 40 | 27 | 22 | 16 | 10 |

| Radius | m | 20~45 | 20~55 | 20~60 | 20~67 | 20~75 | |

| Lifting height | m | 45 | |||||

| Working radius | Max. | m | 73 | ||||

| Min. | m | 20 | |||||

| Speed of mechanism | Lifting speed | m/min | 0.2~10 | ||||

| Luffing speed | m/min | 0.2~10 | |||||

| Slewing speed | r/min | 0.3 | |||||

| Traveling speed | m/min | 30 | |||||

| Power source | Three Phase AC 380V 50Hz | ||||||

| Track gauge/Wheel base | m | 10.5/14 | |||||

| Clear height of portal | m | 8.06 | |||||

| Rotary disc tail slewing radius | m | ~9.4 | |||||

| In-service maximum wind pressure | N/m | 250 | |||||

| Out-ofservice maximum wind pressure | N/m | 1000 | |||||

| In-service maximum wheel pressure | KN | 400 | |||||

| Steel track recommended | P50 | ||||||

| Installed capacity | kw | 350 | |||||

Cases

Export of four-link Portal crane to Sulawesi, Indonesia

Huanghua port project four-link Portal crane

Single Boom Portal crane for CCCC Second Navigation Bureau Project

New Dongyun Single Jib Portal crane