Grab Bucket Overhead Crane for Sale

Grab bucket overhead crane is a kind of lifting equipment which uses grab as a fetching device for material stacking, inverting, fetching, loading and unloading. According to the suitable type of grab, different kinds of materials can be handled.

In actual production, the grab bucket overhead cranes are widely used. Can grab grain, ore, sand, scrap iron, garbage and other bulk goods, commonly used in power plants, yards, workshops, docks and other places.

Types of Grab Bucket Overhead Crane Spreader

Mechanical Clamshell Grab Bucket

- Double-rope and four-rope grabs need to be used in conjunction with cranes that have two sets of hoisting mechanisms (lifting mechanism + opening and closing mechanism) on the trolley.

- Single-rope grabs can be used on various hook overhead cranes but cannot unload in mid-air.

- Suitable for grabbing various bulk materials such as coal, sand, slag, fertilizer, and grains. They are widely used in steel mills, power plants, freight yards, workshops, docks, etc.

- They can be designed in various forms, including toothed bucket, parallel main beam opening, and underwater operation types.

Electric Motor Clamshell Grab Bucket

- Equipped with an electric hoist or winch as an opening and closing mechanism, it is suitable for various hook overhead cranes, allowing for the loading and unloading of materials at any height.

- Suitable for grabbing various bulk materials such as grains and sand. When the grab is made of stainless steel, it is specifically used in the brewing industry for grabbing brewing materials, soy sauce residue, etc. It is often used in breweries, pickle factories, and feed mills, and can also be used for loading and unloading bulk food materials.

- Not suitable for underwater operations.

Hydraulic Clamshell Grab Bucket

- It integrates electrical, hydraulic, and mechanical technologies, providing strong grabbing force and a high degree of automation. It is suitable for various hook overhead cranes.

- Suitable for grabbing powdered and granular bulk materials such as fertilizers, grains, coal, coke, mineral sand, yellow sand, incinerator ash, gravel, etc. It is widely used in settings such as ships and waste incineration plants.

- Not suitable for underwater operations.

Mechanical Orange Peel Grab Bucket

- Double-rope and four-rope grabs need to be used in conjunction with cranes that have two sets of hoisting mechanisms (lifting mechanism + opening and closing mechanism) on the trolley.

- Single-rope grabs can be used on various hook overhead cranes but cannot unload in mid-air.

- Suitable for efficiently handling and unloading large scrap metal and garbage materials in various harsh environments. It has been widely used in industries such as ports, railways, metallurgy, mining, and construction.

- Suitable for underwater operations.

Electric Motor Orange Peel Grab Bucket

- Equipped with an electric hoist or winch as an opening and closing mechanism, it is suitable for various hook overhead cranes, allowing for the loading and unloading of materials at any height.

- Suitable for efficiently handling and unloading large scrap metal and garbage materials in various harsh environments. It has been widely used in industries such as ports, railways, metallurgy, mining, and construction.

- Not suitable for underwater operations.

Hydraulic Orange Peel Grab Bucket

- Integrated with electrical, hydraulic, and mechanical technologies, it features strong gripping force and a high degree of automation, suitable for various hook overhead cranes.

- It is an ideal loading and unloading tool for grabbing bulk materials such as ore, pig iron, scrap steel, and waste piles.

- Not suitable for underwater operations.

Application of Grab Bucket Overhead Crane

Garbage Grab Overhead Crane

- Bridge: European Double Girder Overhead Crane

- Spreader: Hydraulic Orange Peel Grab Bucket

- Application: Garbage grab cranes are installed above garbage storage pits and are primarily responsible for feeding, transporting, mixing, picking, and weighing garbage.

- Feature:

- The garbage grab crane uses PLC, frequency converters, and position encoders for intelligent control, achieving unmanned operation through automatic detection, information processing, data analysis, and manipulation control.

- The control system can utilize imaging technologies such as laser scanners to recognize material level heights, enabling high-level automatic material fetching, automatic feeding, and automatic parking functions.

- The monitoring system can promptly alert users to the equipment’s status and warning information, allowing for quick and convenient adjustments of the hoisting mechanism’s speed and acceleration time at various gears. This helps prevent collisions between the grab and the pit wall, and ensures the grab’s anti-tilt functions.

- In addition to full automatic control, manual and semi-automatic control options are also available.

Slag Handling Grab Overhead Crane

- Bridge: Double Girder Overhead Crane with Two Sets of Hoisting Mechanisms

- Spreader: Four-rope Mechanical Clamshell Grab Bucket

- Application: The slag handling grab overhead crane is specifically designed for handling slag generated during the metallurgical process, such as grabbing slag from blast furnaces in steel mills or from phosphorus slag pools.

- Feature: An automatic control system can be installed to enable the crane to have functions such as automatic slag grabbing, precise positioning, anti-sway, and automatic avoidance. The system can scan and identify the shape, position, and center of gravity of the transported objects.

Steel Scrap Grab Overhead Crane

- Bridge: Double Girder Hook Overhead Crane

- Spreader: Hydraulic Orange Peel Grab Bucket

- Application: Used for grabbing, transporting, and handling scrap steel and other waste materials.

- Feature: Strong grabbing force. The grab is hung on the hook and is detachable. The rated lifting capacity includes the weight of the grab.

Grab Overhead Crane for Brewery

- Bridge: Single Girder or Double Girder Hook Overhead Crane

- Spreader: Stainless Steel Motor Grab Bucket

- Application: Used for grabbing and stirring distiller’s grains in breweries.

- Feature:

- The operating environment is highly corrosive, so the grab bucket is made of 304 stainless steel, and the grab arms, pulleys, and wire ropes are also made of stainless steel.

- The motor has a high protection rating, not less than IP55.

- The wire rope uses a single-rope winding method to prevent rope twisting failures.

Cases of Grab Bucket Overhead Crane

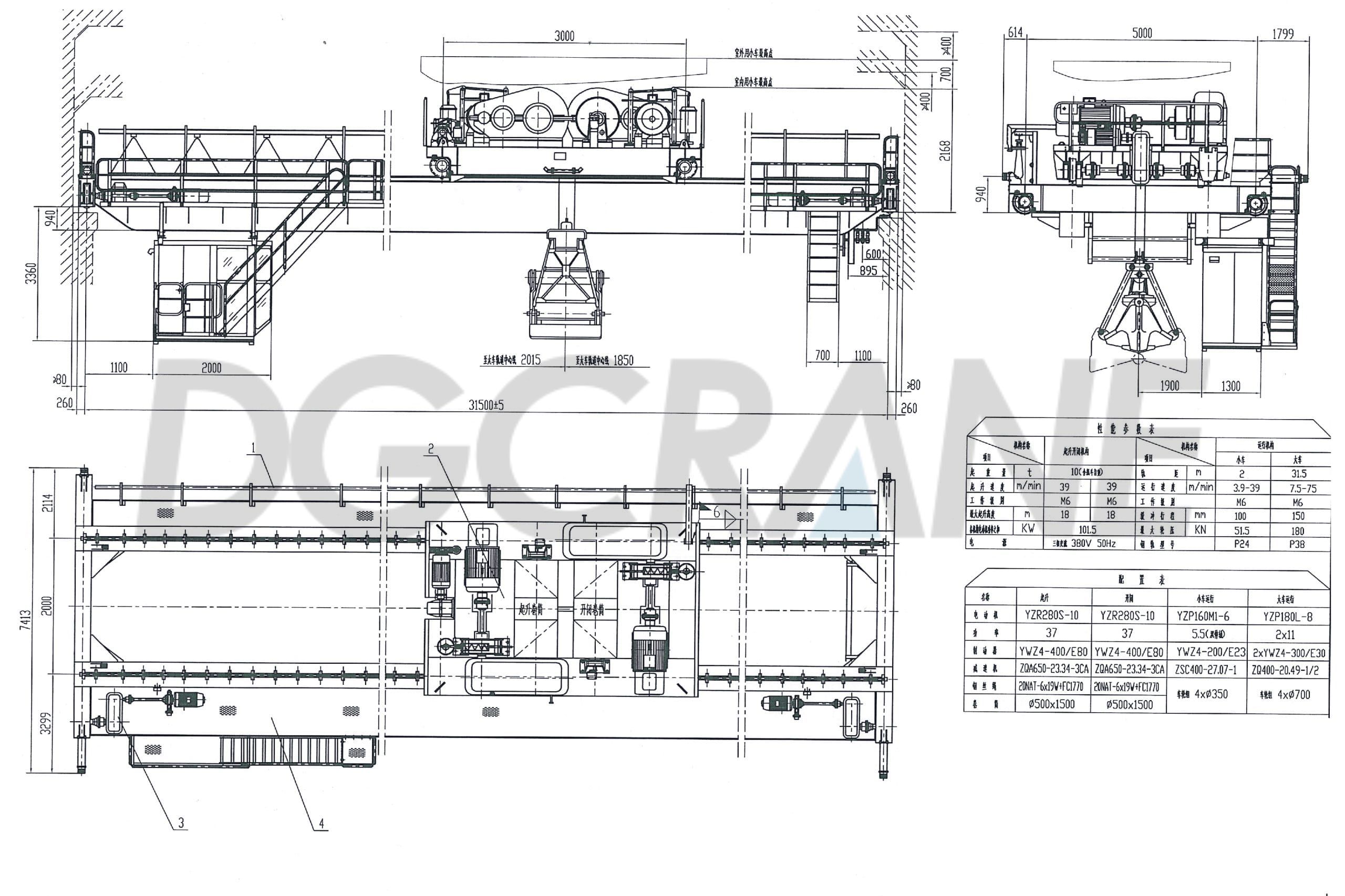

QZ Grab Overhead Crane is Used for Grabbing Construction Materials

|

|

- This crane is suitable for industries such as metallurgy, building materials, chemical, and coal. It is used for loading and unloading bulk materials like ore, slag, coke, coal, and sand in workshops, warehouses, or outdoor fixed spans.

- The crane trolley is equipped with two sets of hoisting mechanisms, each using a double-drum arrangement, symmetrically arranged to control the support rope and the opening and closing rope of the grab. This design ensures convenient operation, stable performance, and high productivity.

- The entire crane features concealed cabling, with galvanized trunking used for wiring the trolley and crane, and rigid hoses used for motor and overload cables. This design protects the cables, prevents human damage, and extends their lifespan.

- The distribution control circuit includes start, stop, emergency switch, power indicator, safety switch, and emergency limit switch for the entire machine’s power supply. It is equipped with short-circuit, over-current, and under-voltage protection. In case of a power supply interruption, the main circuit is automatically disconnected. Each mechanism has zero-position protection, ensuring that if the control handle is not returned to the zero position after a fault recovery, the mechanisms cannot start automatically.

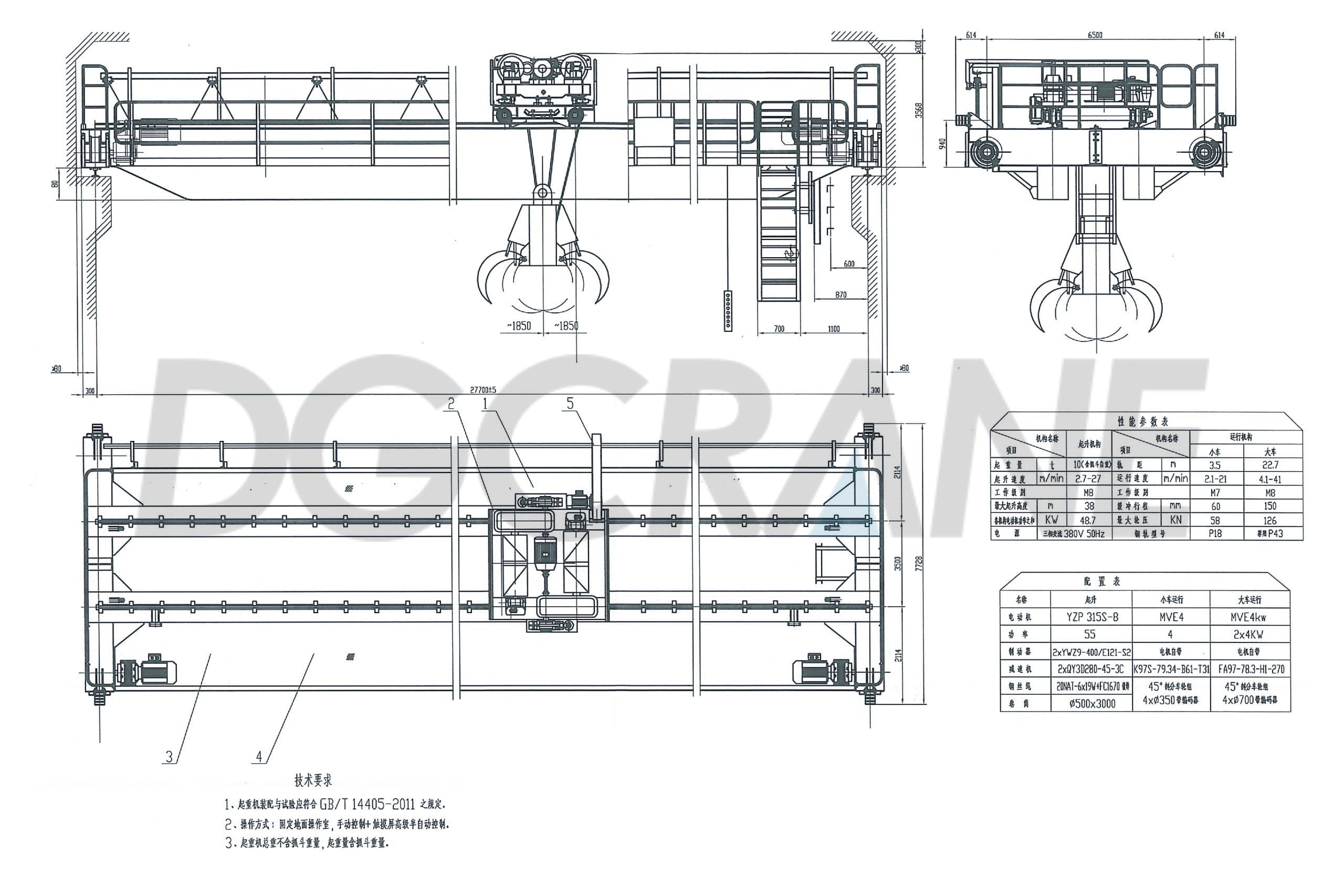

Garbage Grab Crane is Used for Waste-to-energy Projects

|

|

- This crane is used for garbage mixing, stacking, transporting, and stirring, ensuring uniform composition of the waste.

- Designed garbage handling capacity: 600 tons/day.

- All mechanisms of the crane use digital frequency conversion speed control devices, and the entire machine is controlled by PLC, with manual operation available.

- The garbage crane control room is located at the end of the garbage pit, with a separate garbage crane distribution room. The garbage grab crane is operated from the garbage crane control room.

- By clicking the grabbing and feeding positions on the touch screen, the system can automatically perform grabbing, feeding, stacking, and automatic parking processes. It features anti-sway at high lifting heights, real-time dynamic weighing, programmatic control of the grab’s opening and closing, fault diagnosis and alarms, and remote fault diagnosis functions.

- The grab uses a four-point multi-flap hydraulic grab, forming a “V” shaped anti-sway hoisting system with four load-bearing wire ropes. The grab bucket body is made of 16Mn material, and the bottom and side edges are made of high-strength wear-resistant material, Hardox 500.

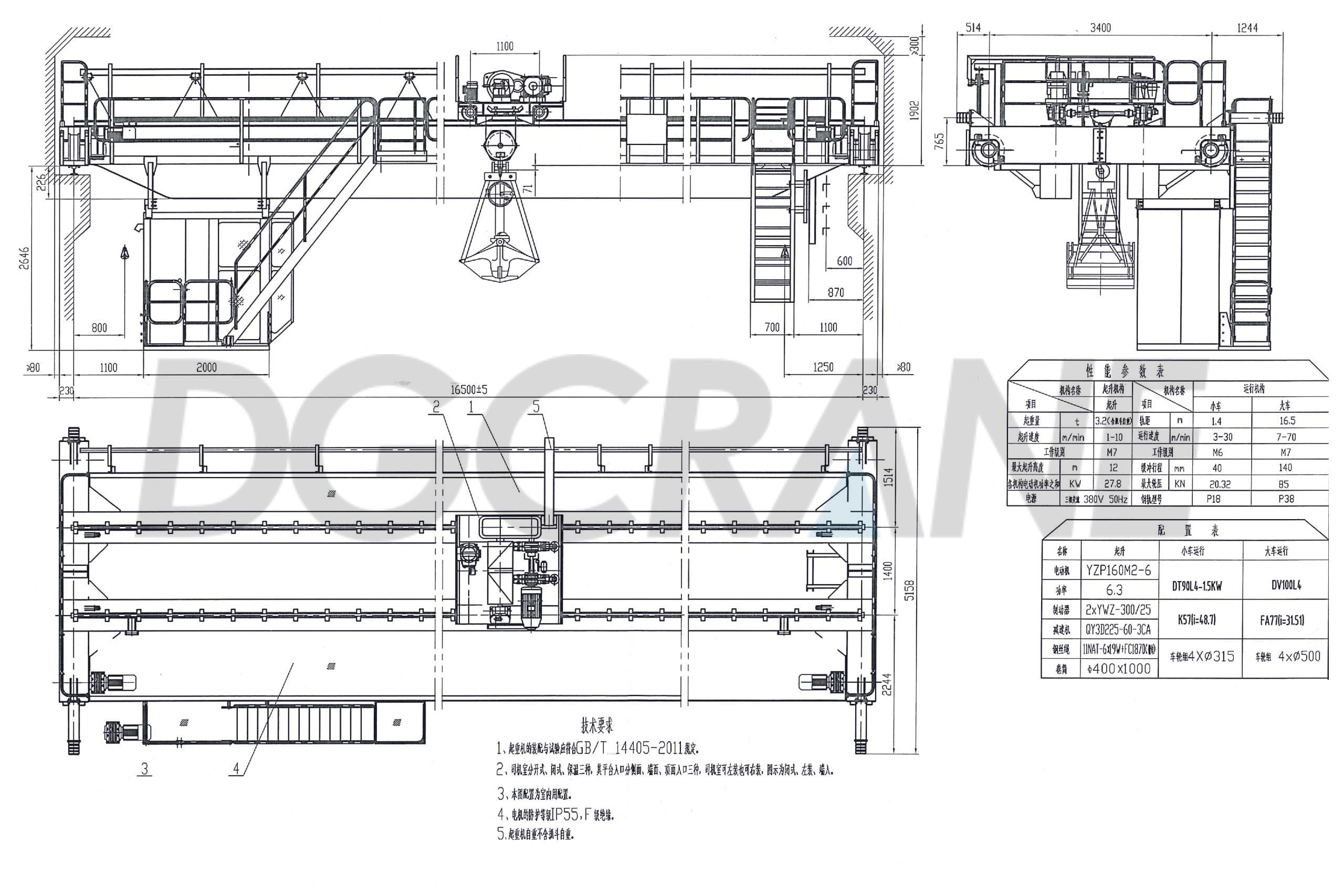

Stainless Steel Grab Crane is Used in Breweries

|

|

- This crane is used in the brewing workshop of a brewery for grabbing distiller’s grains.

- The installation location is indoors, with very high humidity and slightly corrosive water vapor. The sliding contact line often has condensation. Ensure that the protection level of the electrical control cabinet meets the standards, and that the sliding contact line’s protection level is up to standard.

- Grab volume: 1 cubic meter, bucket material is 304 stainless steel, with a thickness of 8mm; material bulk density is 1000 kg/cubic meter.

- All wire ropes are made of galvanized steel wire rope, requiring no maintenance or rust-proof oil. They are of heavy-duty grade, high strength, with a breaking force of no less than 2160N/mm², and a safety factor of no less than 5.

- All motors and control cabinets have a protection level of no less than IP55.

Contact Details

DGCRANE is committed to providing the professional Overhead crane products and relavent service. Exported to Over 100 Countries, 5000+ Customers Choose Us, Worth to be Trusted.

Get In Touch

Fill out your details and someone from our sales team will get back to you within 24 hours!