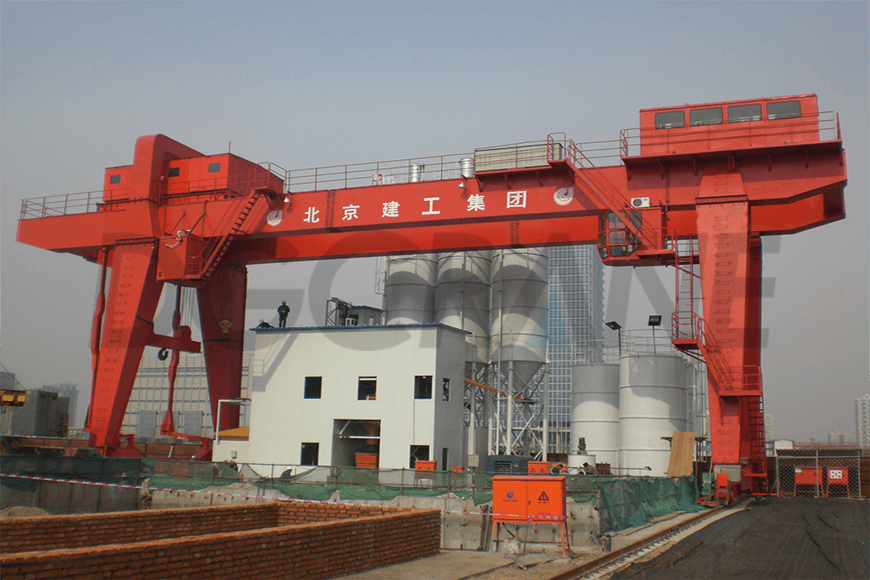

Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

The Gantry Crane for subway and metro construction is widely used in the construction of subways and power tunnels. It is advanced and versatile, capable of operating in various site environments. The lifting height is typically 10m above the track, with a track length of 40m, and the span is variable between 16m and 30m. The crane operates at variable frequency speed control (speed control range 1:10). The crane is equipped with specialized lifting devices: one is a hydraulic-assisted hook that inverts the hopper for aerial unloading; another is a mechanical rotating vertical fixed unloading rack that inverts the hopper for unloading.

Technical Requirements

- The crane’s design, manufacturing, and inspection follow the standards of GB3811-2008 and GB/T14406-2011.

- When not in use, the crane must be locked with a track clamp.

- The working environment temperature for this crane is -20°C to 50°C.

- A cantilever can be used when the span is 24.2m, and it must be removed if the span is less than 24.2m.

- The crane’s span range is 21.2m to 24.2m, with a variable increment of 200mm.

Features for Gantry Crane for Subway and Metro Construction

- Wide speed range, high lifting efficiency: The speed range is 1:10, and the lifting speed can be continuously adjusted according to the load. This allows for low-speed operation under heavy load and high-speed operation under light load, significantly improving the discharge crane’s work efficiency.

- Extremely low stable positioning speed: It can operate under heavy load for long periods at low speeds.

- Smooth and reliable operation: The trolley and hoist systems use variable frequency control, ensuring smooth, step-less transitions between speeds, minimizing mechanical impact.

- Closed-loop control system: It enables the hoist hook to stop at zero speed, significantly extending the service life of the brakes.

- Low current, low heat generation: The motor’s startup current is less than 1.5 times the rated current, reducing the demands on the power grid and preventing overheating during frequent starts, stops, and reversals.

Specification

For more detailed specifications, please refer to DGCRANE’s catalog of gantry cranes for subway and metro construction.

Cases

At DGCRANE, we specialize in providing high-quality, customizable gantry cranes designed for efficiency and reliability. With a focus on innovation and customer satisfaction, we offer tailored solutions to meet the unique needs of each project.

Choose DGCRANE for industry-leading products and exceptional service. Our team is dedicated to supporting your project from design to installation, ensuring optimal performance and smooth operation. Contact us today to learn how we can help make your construction project a success.