Forged Crane Wheels

Forged Crane wheels are a crucial component of a crane’s traveling mechanism. The quality of crane wheels is a key factor in ensuring the safe operation of the crane. The working characteristic of crane wheels is that they work intermittently under heavy load, so the wheels are generally made of forged steel with high strength and good wear resistance, such as 45#, 65Mn, 42CrMo, CL60, etc.

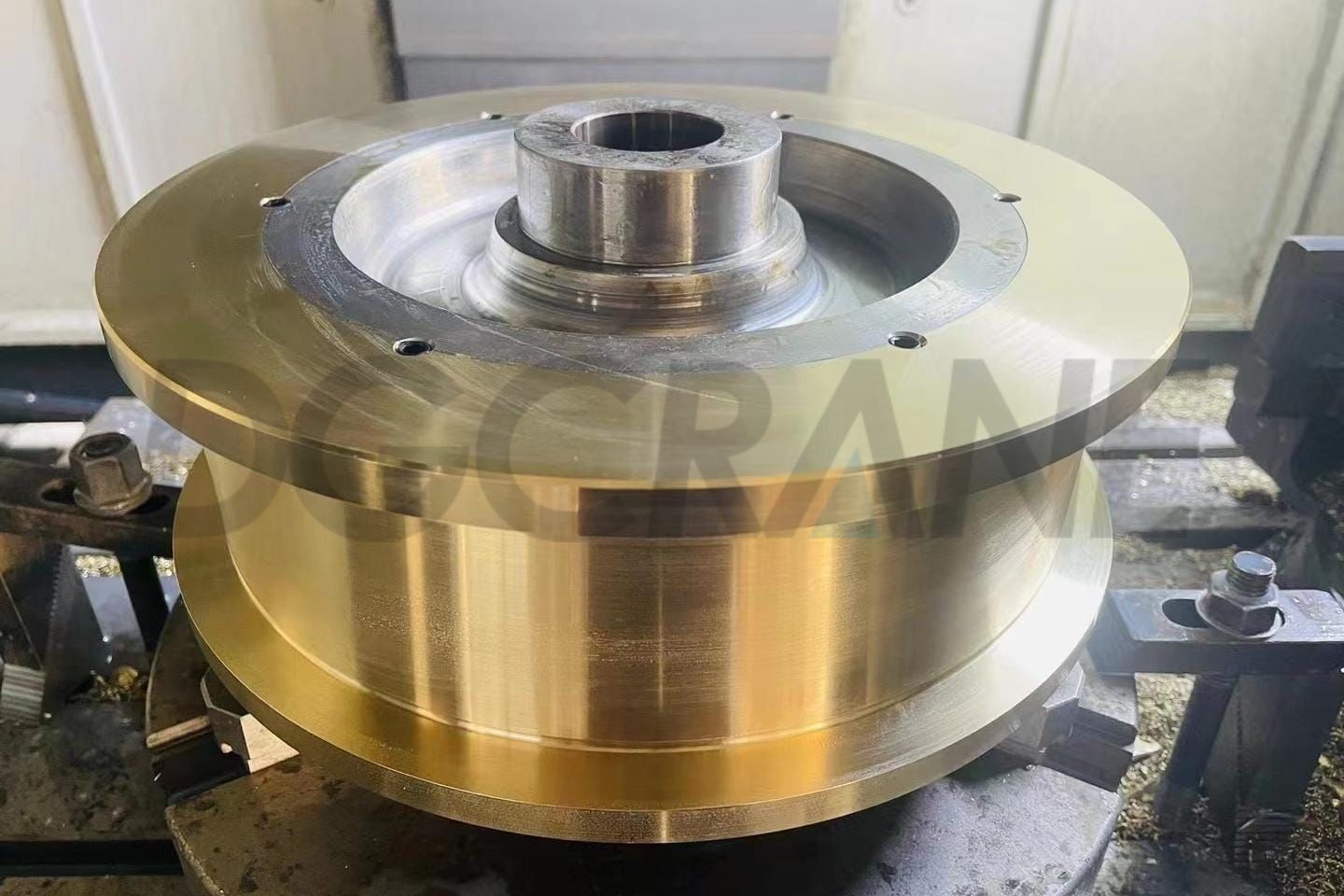

Crane forged wheels use forging processing technology. Through the method of heating and forging, the steel billet undergoes plastic deformation to form the wheel blank, thereby obtaining a dense structure and good mechanical properties, which is a solid-to-solid process. Forged wheel sets, through forging machinery, can optimize the organizational performance of the metal blank and eliminate organizational defects. After forging, the wheels also undergo rough machining, heat treatment, hardness testing, and other production processes.

Forging equipment

Our forging press provides the power necessary to achieve the dramatic reduction ratios and material flow essential in high-quality forgings. This closed-die design provides excellent strength-to-weight ratios necessary for your most critical forging needs. We stock a wide variety of wheel materials to meet your needs.

To realize the rough machining of the outer and inner contour surface of the wheel blank, and clean up the spare parts of the blank quickly. Wheel blanks that we manufacture are used in a wide range of heavy-duty applications including locomotive traction drives, wind turbines, speed reducers, and mining machinery.

Quenching and tempering are widely used as our heat treating capabilities. Heat treating can significantly enhance the mechanical properties of forging by imparting specific hardness, strength, and wear characteristics to meet the requirements of the application. A wide variety of heat treating capabilities are at our disposal to meet virtually any application.

We use a portable hardness tester to test the hardness of the crane wheel set. Inspection of crane wheel tread hardness, along the crane wheel circumferential direction in the tread surface uniform measurement of 3 points, 2 points qualified that is the tread hardness qualified.

Case

From raw materials to final inspection and shipment, we always adhere to a comprehensive quality assurance program to meet our customers’ most demanding requirements.

We maintain a large inventory of carbon and alloy steels to meet your specific needs. Forged Crane Wheels are available in any surface hardness up to HRC50 including our standard heat treatments.

Forged Steel Crane Wheels are available in a wide range of standard sizes. In addition, crane wheels to meet your special design requirements can be produced in virtually any size configuration and surface finish condition.