Explosion-Proof Overhead Crane Wheels: Enhanced Safety for Hazardous Environments

Explosion-proof overhead crane wheels are mainly used in explosion-proof cranes, mining cranes, explosion-proof electric flat cars, and mining vehicles in flammable and explosive environments. The commonly used explosion-proof wheelsets are tread surfaced stainless steel wheels. The base of these wheels is low-carbon steel cast wheels. Since low-carbon steel has good weldability, there are no defects such as cracks after welding.

Explosion-Proof Crane Wheel Material

Currently, explosion-proof overhead crane wheels are generally made from 65Mn and CL60. Considering the working characteristics of crane wheels, certain chemical composition and mechanical performance requirements must be met.

- CL60 steel has high strength, hardness, and elasticity, but lower plasticity during cold deformation. It is more suitable for high-speed operation wheels. During the operation of crane wheels, high strength, wear resistance, and certain elasticity are required, making CL60 a suitable material.

- 65Mn is a high-quality carbon structural steel commonly used as spring steel. It has higher strength, hardness, elasticity, and hardenability than general steel. The heat treatment for crane wheels typically involves quenching and tempering, resulting in a tempered troostite structure. This structure has a high elastic limit and yield limit, as well as a certain toughness. 65Mn possesses these advantages and is also inexpensive and readily available, making it suitable for use in cranes.

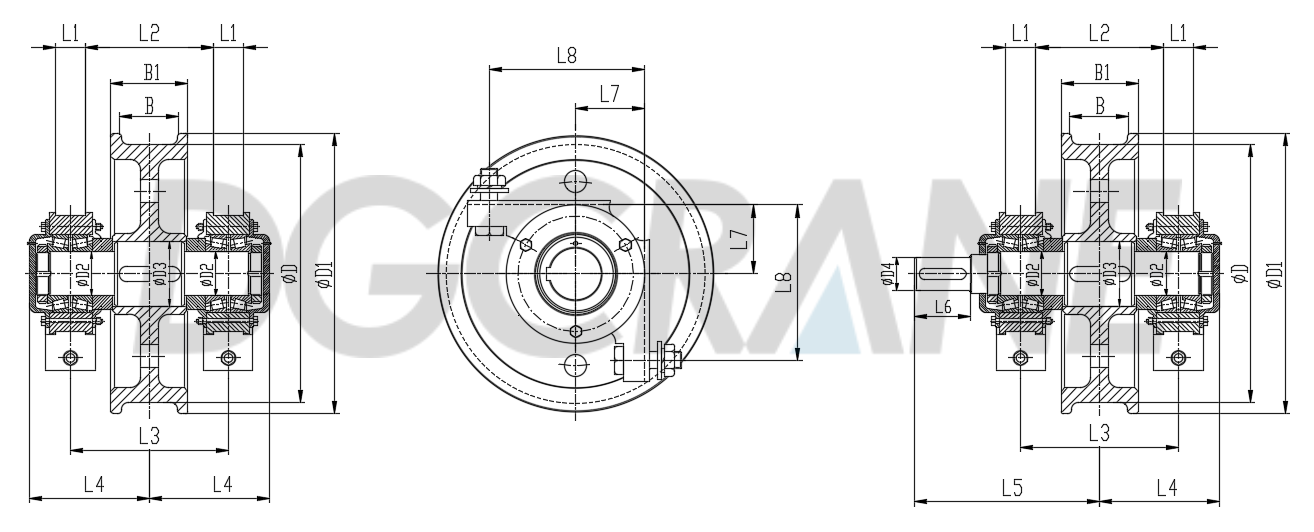

Parameters of Explosion-Proof Crane Wheels

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 50 | 230 | 280 | 230 | 400 | 105 | 140 | 310 | 271~293 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 264~286 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 80~150 | 130~210 | 50 | 230 | 280 | 230 | 415 | 130 | 140 | 310 | 316~381 | |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 306~381 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 80 | 235 | 315 | 260 | 455 | 130 | 160 | 350 | 502~542 |

| Passive crane wheels ø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 80 | 235 | 315 | 260 | / | / | 160 | 350 | 489~534 |

| Active crane wheels ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 90 | 275 | 365 | 300 | 500 | 130 | 190 | 410 | 742~823 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 90 | 275 | 365 | 300 | / | / | 190 | 410 | 729~810 |

Stainless Steel Overlay Welding Process

Explosion-proof overhead crane wheels typically use a stainless steel overlay welding process to enhance their corrosion and wear resistance.

Surface Temperature of Explosion-Proof Crane Wheels

The surface temperature of explosion-proof overhead crane wheels refers to the temperature reached by any component of the electrical equipment that might ignite the surrounding explosive environment under specified adverse operating conditions. The surface temperature should be lower than the ignition temperature.

Customized Service

DGCRANE can provide various types of explosion-proof crane wheels and customized non-standard designs according to your specific requirements. If you have any requirements, please feel free to contact us!