Explosion Proof Manual Chain Hoist: Safety in Every Lift

The force-bearing friction parts of DGCRANE explosion-proof manual chain hoists are made of materials such as beryllium bronze, aluminum bronze, and brass. They are suitable for hazardous environments and comply with the ATEX standards. These explosion proof products are robust and durable, featuring appropriate protective measures to ensure safety and a longer service life under harsh operating conditions. We offer explosion-proof and spark-resistant hand chain hoists with fixed suspension, manual push, geared, and electric trolleys for various applications.

- Lifting Capacity: 0.5t, 1t,1.5t, 2t, 3t, 5t, 10t,20t,30t

- Working Temperature: -25℃~40℃

- Altitude: Below 1000m

- Protection Grade: IP65/IP66

- Application: Capable of preventing explosions of gas (G) and dust (D).

Product Parameters

| Capacity | tons | 0.5 | 1 | 1.5 | 2 | 3 | 5 | 10 | 20 | 30 |

|---|---|---|---|---|---|---|---|---|---|---|

| Lifting height | m | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 3 | 3 |

| Test load | KN | 7.5 | 15 | 22.5 | 30 | 45 | 75 | 150 | 300 | 450 |

| Maximum hand tension | N | 225 | 300 | 310 | 310 | 350 | 400 | 410 | 410×2 | 410×2 |

| Number Of load chain | 1 | 1 | 1 | 2 | 2 | 2 | 4 | 8 | 12 | |

| Diameter of load chain | mm | 5 | 6 | 7.1 | 6 | 7.1 | 9 | 9 | 10 | 10 |

| Weight | Kg | 6.25 | 10.6 | 13 | 15.3 | 21 | 38 | 70 | 156 | 246 |

| Box size | cm | 22×15×18 | 25×18×18.5 | 30×20×20 | 29×22×22 | 34×23×18 | 47×28×22 | 49×46×25 | 80×70×23 | 80×70×37 |

| Increased weight for every 1m increase in lifting height | Kg | 1.8 | 1.8 | 2.1 | 3.6 | 4.2 | 5.1 | 9.3 | 19.3 | 28.3 |

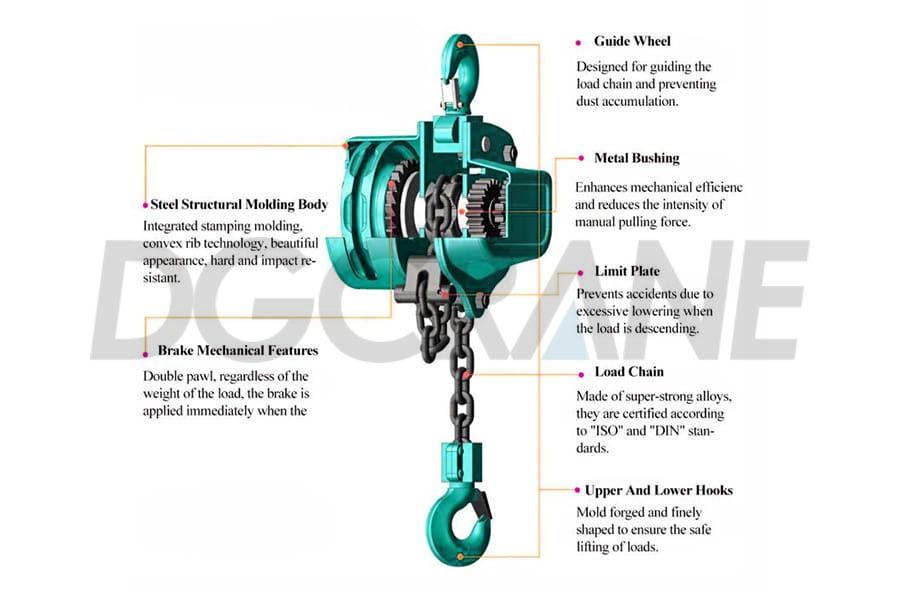

Features of Explosion-Proof Manual Chain Hoist

Applications

Explosion-proof manual chain blocks play a crucial role in places with limited environments, operating where large equipment cannot. These ex proof hoists do not require electricity for operation, feature a simple internal structure, and are easy to assemble and disassemble, facilitating maintenance. They are portable and easy to operate with minimal effort.

They can be widely used in industries such as petroleum, petrochemicals, gas stations, oil depots, gas extraction, chemicals, mining, electronics, railways, shipbuilding, and more. Suitable for gas and dust hazard areas Zone 1, Zone 2, Zone 21, Zone 22, as well as underground in coal mines.

Explosion-Proof Certificates

Our explosion-proof products have passed the IECEx for global standards, ATEX for Europe, CCC, Mining Safety Certificate, and Explosion-Proof Qualification Certificate for China.

Explosion-Proof Equipment Services

DGCRANE provides necessary spare parts and professional installation and maintenance services for all explosion-proof electric chain hoists.

- Spare Parts

We prepare the necessary spare parts for explosion-proof manual chain hoists so that explosion proof components can be replaced in a timely manner when their service life ends, ensuring the safety of the explosion-proof manual chain hoist and the working environment, reducing maintenance and inspection time, and improving production efficiency. - Installation

If needed, we can provide accompanying installation services, with our engineers coming to your location for installation. If you prefer to handle the installation yourself, we will inform you of the qualifications required for the installation workers you need to hire, and provide detailed installation steps and precautions in a manual along with remote guidance. - Maintenance

Accompanying the explosion-proof equipment delivery, we provide manuals on product use and maintenance. During the explosion proof product’s service period, we offer consultation services and solutions for any issues that may arise.

Explosion-Proof Hoist Knowledge

DGCRANE has specialized in exporting explosion proof hoists for 13 years, with products sold to over 120 countries. We offer customized crane solutions and transportation plans tailored to your needs. For any inquiries, please contact us. DGCRANE is dedicated to providing you with the best service possible.