Explosion Proof Double Girder Overhead Crane: More Cost Effective

- Capacity: 5~100/30t

- Span: Up to 31.5m

- Duty Group: A4

- Minimum Electrical Enclosure: IP65/IP66

- Operating Environment Temperature: -25°C to +40°C

- Relative humidity ≤85%

- Explosion Proof Marking: ExdIIBT4、ExdIICT4

- Power Supply Voltage: 3P, A.C, 380 V, three-phase, 50HZ

- Application Scope: Inflammable gas or explosive gas mixture formed by steam and air with ignition temperature group T1-T4, suitable for hazardous areas Zone 1 and Zone 2

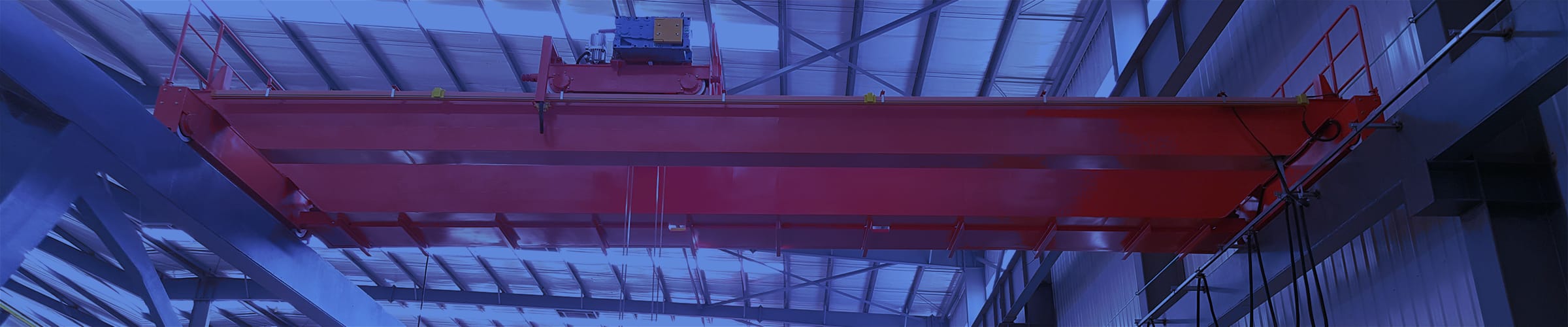

Overview

The explosion-proof double girder bridge crane is designed and manufactured to withstand explosions. Built on the foundation of standard bridge cranes, it is equipped with explosion-proof motors and electrical explosion proof components, along with other auxiliary mechanical explosion-proof measures, to ensure that the explosion-proof double girder overhead crane does not cause fires, explosions, or other hazards when operating in explosive environments. The explosion-proof mark is Ex.

All components of the explosion-proof double girder overhead crane are carefully selected for use in hazardous environments such as military handling, painting workshops, mining, chemical plants, petrochemical plants, refineries, gas-fired power plants, wastewater treatment facilities, and spray painting workshops.

Features of Explosion-Proof Double Girder Overhead Crane

- The explosion-proof double girder overhead crane uses stainless steel or nylon lifting blocks to avoid flames caused by friction.

- The ex proof crane and trolley wheel surfaces are made of stainless steel or beryllium bronze steel, materials less likely to produce sparks.

- Equipped with soft start explosion-proof motors for smooth operation, reducing impact and spark resistance.

- Designed with good rigidity and strong explosion-proof capabilities.

- All our explosion-proof double girder overhead cranes are manufactured in accordance with GB 3836.2-2010 and JB/T 5897-2014 standards, ensuring safety, reliability, extreme durability, low maintenance, and a long service life.

- Features automatic cutoff of lifting movement at upper and lower positions.

- Electronic overload protection.

- High component interchangeability, facilitating easy replacements.

- External parts of the explosion proof double girder overhead crane are made from non-sparking materials for explosion-proof safety.

Explosion-Proof Certificates

Our explosion-proof products have passed the IECEx for global standards, ATEX for Europe, CCC, Mining Safety Certificate, and Explosion-Proof Qualification Certificate for China.

Explosion-Proof Equipment Services

DGCRANE provides necessary spare parts and professional installation and maintenance services for all explosion-proof electric chain hoists.

- Spare Parts

We prepare the necessary spare parts for all explosion-proof electric chain hoists so that explosion proof components can be replaced in a timely manner when their service life ends, ensuring the safety of the explosion-proof electric chain hoist and the working environment, reducing maintenance and inspection time, and improving production efficiency. - Installation

If needed, we can provide accompanying installation services, with our engineers coming to your location for installation. If you prefer to handle the installation yourself, we will inform you of the qualifications required for the installation workers you need to hire, and provide detailed installation steps and precautions in a manual along with remote guidance. - Maintenance

Accompanying the explosion-proof equipment delivery, we provide manuals on product use and maintenance. During the explosion proof product’s service period, we offer consultation services and solutions for any issues that may arise.

FAQs

Are explosion proof overhead cranes more expensive than traditional cranes?

Yes, explosion proof overhead cranes are typically more expensive due to their specialized components and design features.

Can explosion proof overhead cranes be customized for specific applications?

Yes, manufacturers offer a range of options to customize explosion proof overhead cranes for specific industries and applications.

What regulations require the use of explosion proof bridge cranes?

Regulations from organizations such as OSHA and ATEX require the use of explosion proof overhead cranes in hazardous environments.

How often should explosion proof overhead cranes be maintained?

Maintenance schedules for explosion proof overhead cranes vary depending on the specific application, but regular inspections and preventative maintenance are essential to ensure safe and efficient operation.

Can explosion proof overhead cranes be used in wet or humid environments?

Yes, explosion proof overhead cranes can be designed and built to operate safely in wet or humid environments.

Explosion-Proof Double Girder Overhead Crane Knowledge PDF

DGCRANE has specialized in exporting explosion proof hoists for 13 years, with products sold to over 120 countries. We offer customized crane solutions and transportation plans tailored to your needs. For any inquiries, please contact us. DGCRANE is dedicated to providing you with the best service possible.