Crane Wheel Block Assembly

The structural forms of cranes are constantly evolving, and the diameter of crane wheels is developing towards smaller sizes. The forms of crane wheel assembly are also becoming increasingly diverse. This article lists several types of crane wheel assemblies in the field of lifting and transportation machinery, for everyone's reference in your work.

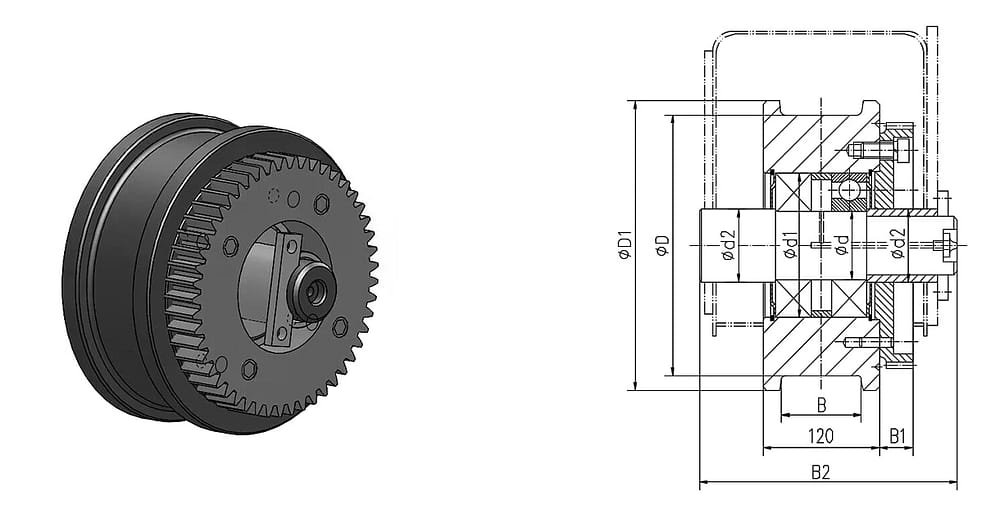

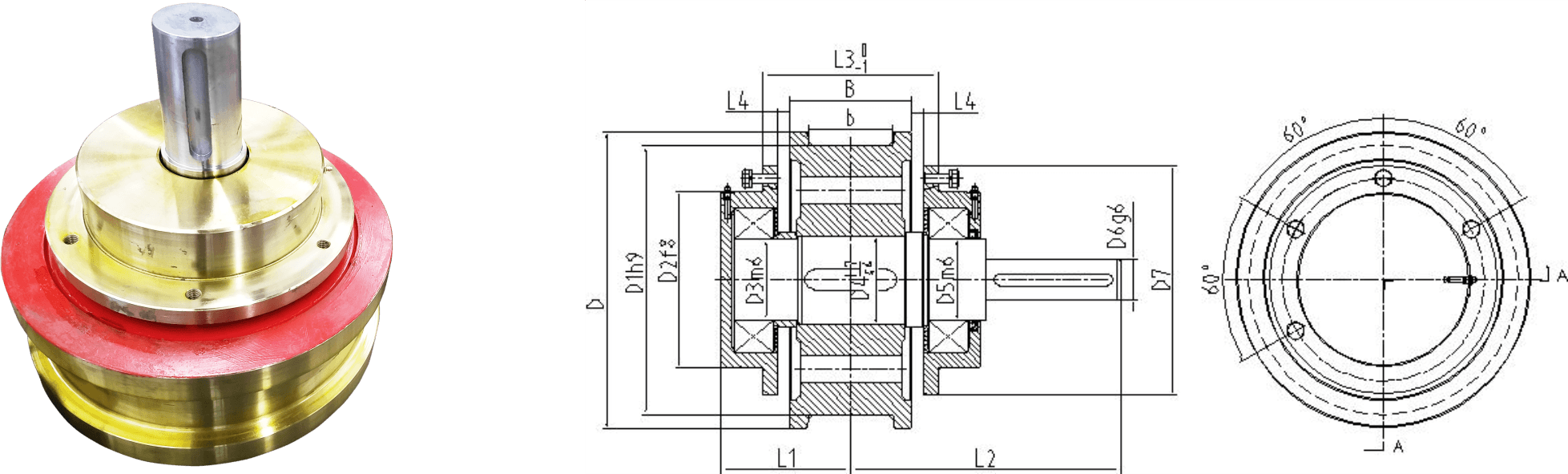

Gear crane wheel assembly

Applicable Scenarios:

Mainly used in single-girder cranes, small-tonnage double-girder cranes with a hoist, and Single-Beam Gantry Cranes Below 10 Tons. So it is commonly used as an overhead crane wheel assembly and gantry crane wheel assembly.

Composition:

The gear crane wheel assembly mainly consists of a wheel axle, wheel, bearings, and a gear ring, comprising four parts.

Features:

- This LD crane wheel assembly does not have a bearing box; bearings are directly installed inside the wheel, making the structure simple, cost-effective, and the components highly interchangeable for easy procurement.

- It is inconvenient to adjust when the crane wheel experiences rail biting or derailment.

- The replacement and disassembly of the crane wheel are relatively cumbersome.

Crane Wheel Materials:

- The material of the LD crane wheel axle is 45# steel, hardened to a hardness of HB217-HB255 through conditioning treatment.

- The LD crane wheel is cast from 45# steel, with the tread surface of the crane wheel assembly heat-treated to a hardness of HB300-HB380.

- The gear ring is forged from 40Cr, with the gear surface having a hardness of HRC48-55 due to surface quenching.

Size Parameters:

The main specifications are two sizes: LD300 and LD400, with groove widths of 70 and 90mm.

| Model | D | D1 | d | d1 | d2 | B | B1 | B2 |

|---|---|---|---|---|---|---|---|---|

| LD300 | ø270 | ø300 | ø70 | ø150 | ø75 | 70 | 38 | 270 |

| LD400 | ø370 | ø400 | ø90 | ø190 | ø100 | 90 | 40 | 280 |

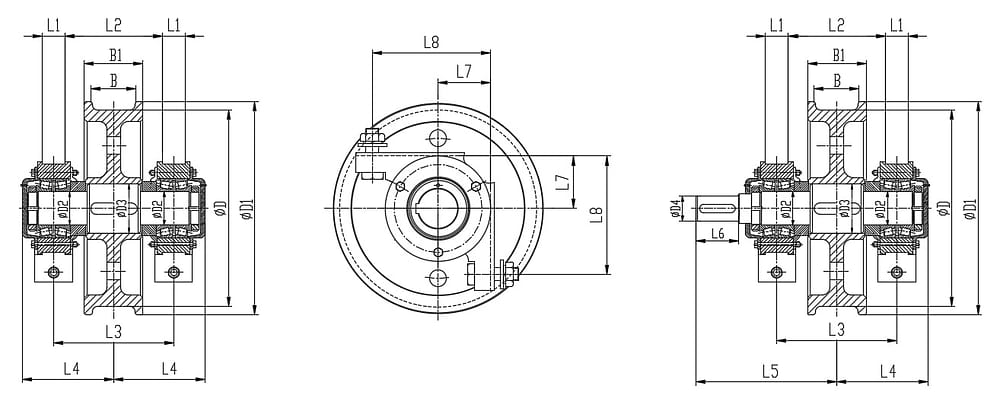

L block crane wheel assembly

Applicable Scenarios:

Double flange L block crane wheel assemblies are primarily used in gantry cranes, running mechanisms of double girder bridge cranes, casting cranes, electric flat cars, trolley groups, ship unloaders, shipyards, port machinery, coal unloaders, stacker reclaimers, shore bridges, etc.

Composition:

Angular box-type crane wheel assemblies mainly consist of four parts: wheel axle, wheel disc, angular bearing box, and bearings.

Features:

- When crane wheel derailment or biting occurs, the adjustment of the angular box-type structure is the most convenient. The angular box-type bearing seat uses horizontal and vertical key plates welded to the frame for wheel positioning. When derailment or biting occurs, the welds can be cut on-site to adjust the wheel and key plates before re-welding them to the frame, without cutting the end beam.

- Compared to European-style crane wheel assemblies, the disassembly and assembly of the angular box wheel are more convenient during wheel replacement.

Crane Wheel Material:

- The material of the crane wheel is often high manganese alloy or cast steel wheel.

- Cast steel crane wheel assemblies include cast 55, cast 50SiMn, and cast 42CrMo.

- Forged steel crane wheel assemblies include forged 60, forged 42CrMo, and forged 65Mn.

Size Parameters:

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 50 | 230 | 280 | 230 | 400 | 105 | 140 | 310 | 271~293 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 264~286 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 80~150 | 130~210 | 50 | 230 | 280 | 230 | 415 | 130 | 140 | 310 | 316~381 | |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 50 | 230 | 280 | 230 | / | / | 140 | 310 | 306~381 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 80 | 235 | 315 | 260 | 455 | 130 | 160 | 350 | 502~542 |

| Passive crane wheels ø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 80 | 235 | 315 | 260 | / | / | 160 | 350 | 489~534 |

| Active crane wheels ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 90 | 275 | 365 | 300 | 500 | 130 | 190 | 410 | 742~823 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 90 | 275 | 365 | 300 | / | / | 190 | 410 | 729~810 |

45°Split Bearing Box Crane Wheel Assembly

Applicable Scenarios:

Used for the travel mechanisms of large lifting equipment.

Composition:

The 45°split bearing box-type crane wheel assembly mainly consists of four parts: the wheel axle, wheel disc, 45°split bearing box, and bearings.

Features:

- The most convenient structure for disassembly and assembly, facilitating the maintenance and replacement of crane wheels.

- In the event of crane wheel biting or derailment, it is not suitable for adjustment.

- These crane wheels are commonly used in heavy lifting equipment under high wheel pressure conditions, equipped with self-aligning bearings. In addition to extensive machining and heat treatment of the chromium alloy used in the lateral installation of wheels, the design of the wheels also emphasizes installation on the ends of the web plate of the end beam, effectively protecting the installation bolts from high-stress areas.

- The web plate is welded to the support ring, which is more reliable under heavy loads and vibrations than side shear bolts. Although the material of the support ring is different from that of the end beam web plate, modern welding techniques have overcome this issue.

- The straightness and parallelism control of this type of crane wheel is not as precise as that of wheels mounted on the side of the web plate, requiring the use of spherical outer bearings to correct the running posture of the wheel.

Wheel Assembly Material:

- The material of the wheel is often high manganese alloy or cast steel wheel.

- Cast steel wheel assemblies include cast 55, cast 50SiMn, and cast 42CrMo.

- Forged steel wheel assemblies include forged 60, forged 42CrMo, and forged 65Mn.

Size Parameters:

| Item | D | D1 | D2 | D3 | D4 | B | B1 | L1 | L2 | L3 | L4 | L5 | L6 | Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Active crane wheels ø500 | 500 | 540 | 100 | 105 | 75 | 80~130 | 130~180 | 100 | 180 | 280 | 230 | 400 | 105 | 276~298 |

| Passive crane wheels ø500 | 500 | 540 | 100 | 105 | / | 80~130 | 130~180 | 100 | 180 | 280 | 230 | / | / | 269~291 |

| Active crane wheels ø600 | 600 | 640 | 100 | 105 | 85 | 80~150 | 130~210 | 100 | 180 | 280 | 230 | 415 | 130 | 321~386 |

| Passive crane wheels ø600 | 600 | 640 | 100 | 105 | / | 80~150 | 130~210 | 100 | 180 | 280 | 230 | / | / | 311~386 |

| Active crane wheels ø700 | 700 | 750 | 120 | 125 | 90 | 100~150 | 150~200 | 120 | 195 | 315 | 260 | 455 | 130 | 507~547 |

| Passive crane wheelsø700 | 700 | 750 | 120 | 125 | / | 100~150 | 150~200 | 120 | 195 | 315 | 260 | / | / | 494~539 |

| Active crane wheel ø800 | 800 | 850 | 150 | 155 | 95 | 100~150 | 150~210 | 140 | 225 | 365 | 300 | 500 | 130 | 747~828 |

| Passive crane wheels ø800 | 800 | 850 | 150 | 155 | / | 100~150 | 150~210 | 140 | 225 | 365 | 300 | / | / | 734~815 |

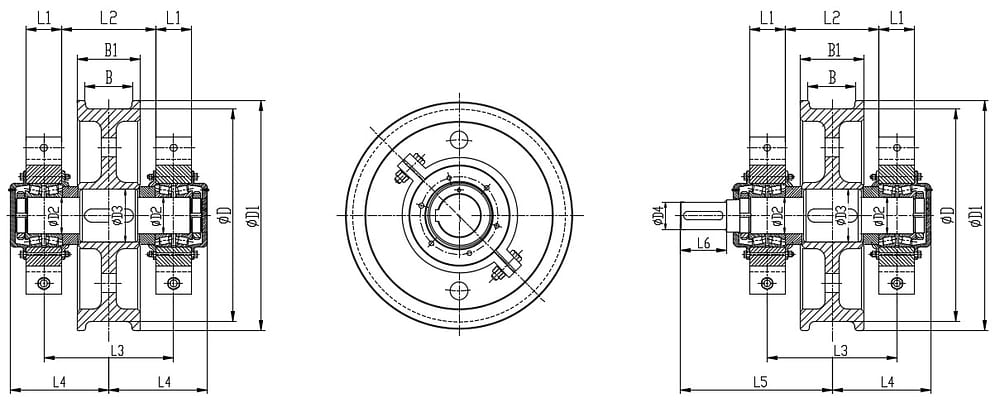

European crane wheel assembly

Round Bearing Box European crane wheel assembly & Square Bearing Box European crane wheel assembly

Round Bearing Box European crane wheel assembly & Square Bearing Box European crane wheel assembly

Applicable Scenarios:

Mainly used in the more advanced European-style cranes of the present day.

Composition:

European-style crane wheel assemblies mainly consist of four parts: the wheel axle, wheel disc, bearing box, and bearings.

Features:

- European-style crane wheels have superior material performance, allowing for smaller diameters under the same load conditions, a more compact structure, and a sleek design thanks to integral boring and milling processes and modern electrical heating treatment. They are lighter in weight and smaller in size.

- Since they need to directly match with a three-in-one reducer without connecting through a coupling, these wheel assemblies require very high assembly precision.

- The bearing box is directly bolted to the end beam web plate, making it difficult to adjust when crane wheel biting occurs, and harder to disassemble compared to the angular bearing box structure.

- A smaller wheel diameter leads to increased curvature, smaller contact area with the track, and increased wheel-rail contact stress under the same wheel pressure. Ensuring the same running speed with a smaller diameter increases the wheel’s rotational speed and tread wear.

- Under minor changes in wheel pressure, the input torque is significantly reduced. There is a substantial difference between the diameter of the wheel axle bearing the load and the wheel axle transmitting the torque, resulting in excessive space between axles, leading to waste in terms of raw materials and labor.

- The square bearing box wheel assembly has a positioning pin when it is installed, and the positioning accuracy is higher than that of the round bearing box wheel assembly , but it is not convenient to disassemble.

Material:

Extensively uses forged chromium alloy materials.

Parameters:

Main specifications include: ø160, ø200, ø250, ø315, ø400, ø450, ø500.

| Item | D | D1 | D2 | D3 | D4 | D5 | D6 | D7 | L1 | L2 | L3 | L4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 230 | 200 | 120 | 50 | 55 | 50 | 40 | 180 | 101 | 195 | 136 | 12 |

| 250 | 280 | 250 | 150 | 60 | 65 | 60 | 40 | 210 | 120 | 235 | 174 | 12 |

| 315 | 355 | 315 | 180 | 70 | 75 | 70 | 45 | 250 | 145 | 237 | 200 | 15 |

| 400 | 440 | 400 | 260 | 120 | 130 | 120 | 60 | 340 | 192 | 408 | 260 | 22 |

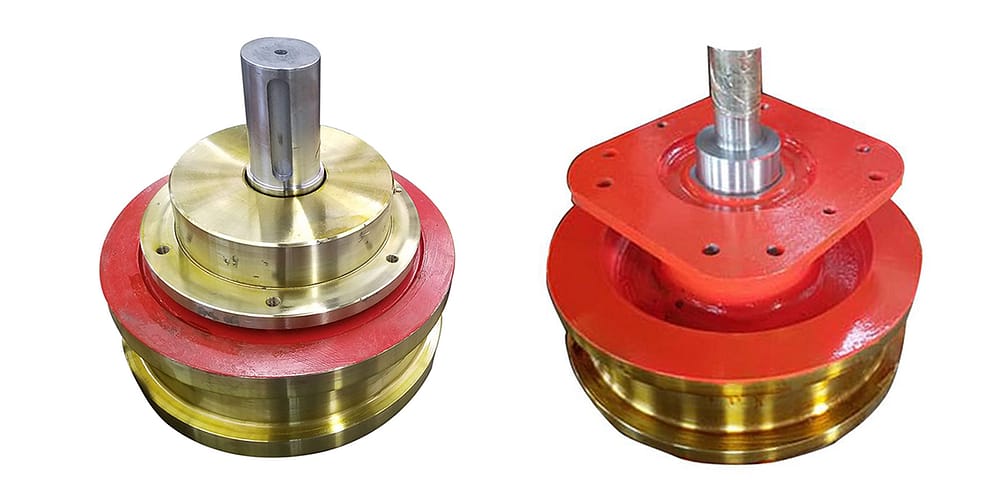

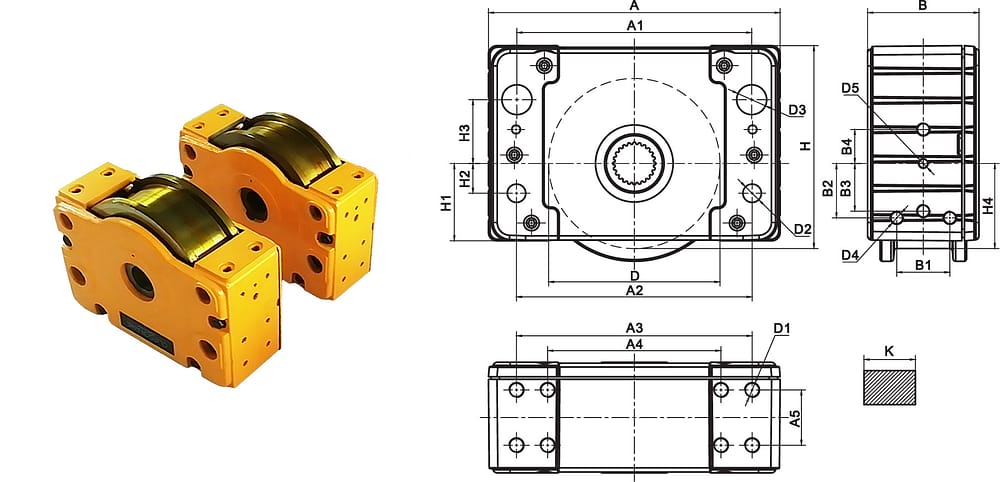

DWB wheel blocks

Applicable Scenarios:

Mainly used in stackers, shield machines, equipment supporting, metallurgical trolleys, and other industries.

Features:

- Very easy to assemble, simple wheel change.

- Fully enclosed design, lifetime mamaintenance-free

- The ball-milled cast iron travel wheel has self-lubricating function and wear resistance, and its design service life is up to ten years.

- Big bearing capacity of the wheel block, light traveling sound.

- Spline hub of driving wheel, connected with spline of reducer, compact structure and reasonable design.

- Five finishing surfaces, convenient connection with structure, ensure accurate installation.(Top connection, Side connection, Pin connection, End connection)

- Modular standard design, full set of walking solutions and components, greatly simplifies the design costs and time for the crane walking mechanism.

Crane Wheel Material:

spheroidal-graphite cast iron

Technical Parameters:

wheel load from 2.75 tons to 40 tons, scientific series division (DWB112~DWB500)

| TypeD | Amm | Bmm | Hmm | Kmm | H1mm | H2mm | H3mm | H4mm | B1mm | B2mm | B3mm | B4mm |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DWB112 | 190 | 96 | 131 | 55 | 47 | 30 | 40 | 80 | 40 | 30 | / | 24 |

| DWB125 | 220 | 98 | 147.5 | 55 | 53.5 | 20 | 40 | 100 | 50 | 37 | / | 37.5 |

| DWB160 | 275 | 110 | 187 | 60 | 70 | 25 | 55 | 100 | 54 | 47.5 | / | 20 |

| DWB200 | 340 | 130 | 238 | 60 | 90 | 35 | 75 | 100 | 62 | 64 | 56 | 40 |

| DWB250 | 385 | 150 | 281 | 75 | 89 | 50 | 80 | 100 | / | / | / | / |

| DWB315 | 470 | 180 | 349.5 | 90 | 114 | 70 | 80 | 100 | / | / | / | 30 |

| DWB400 | 580 | 210 | 440 | – | 144 | 95 | 130 | 100 | / | / | / | 30 |

| DWB500 | 700 | 240 | 566 | – | 183 | 110 | 160 | 100 | / | / | / | 30 |

| TypeD | A1mm | A2mm | A3mm | A4mm | A5mm | D1 | D2mm | D3mm | D4 | D5 | WeightkG | Max. LoadkN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DWB112 | 145 | 145 | 145 | / | 45 | 4*M12 | 10.5 | 18.5 | 4*M12 | 2*M12 | 10 | 27.5 |

| DWB125 | 175 | 175 | 170 | / | 55 | 4*M12 | 13 | 21 | 4*M12 | 2*M12 | 15 | 50 |

| DWB160 | 220 | 220 | 220 | / | 55 | 4*M16 | 17 | 30 | 4*M16 | 2*M12 | 26 | 70 |

| DWB200 | 275 | 275 | 275 | / | 65 | 4*M16 | 20 | 35 | 8*M16 | 2*M12 | 41 | 100 |

| DWB250 | 310 | 310 | 290 | 140 | 80 | 8*M16 | 34F8 | 40 | 2*M12 | / | 70 | 160 |

| DWB315 | 370 | 370 | 360 | 180 | 100 | 8*M16 | 40F8 | 50 | 2*M12 | 2*M20 | 130 | 220 |

| DWB400 | 450 | 450 | 440 | 210 | 120 | 8*M20 | 31H13 | 65 | 2*M12 | 2*M20 | 220 | 300 |

| DWB500 | 580 | 580 | 620 | 480 | 125 | 8*M20 | 31H13 | 70 | 2*M12 | 2*M20 | 380 | 400 |