Copperhead Conductor Rails: Ideal for High Temperature, High Humidity, and Corrosive Environments

The copperhead conductor rails are a device used to provide power to mobile equipment, commonly found in places like industrial enterprises and mines, such as cranes and electric hoists.

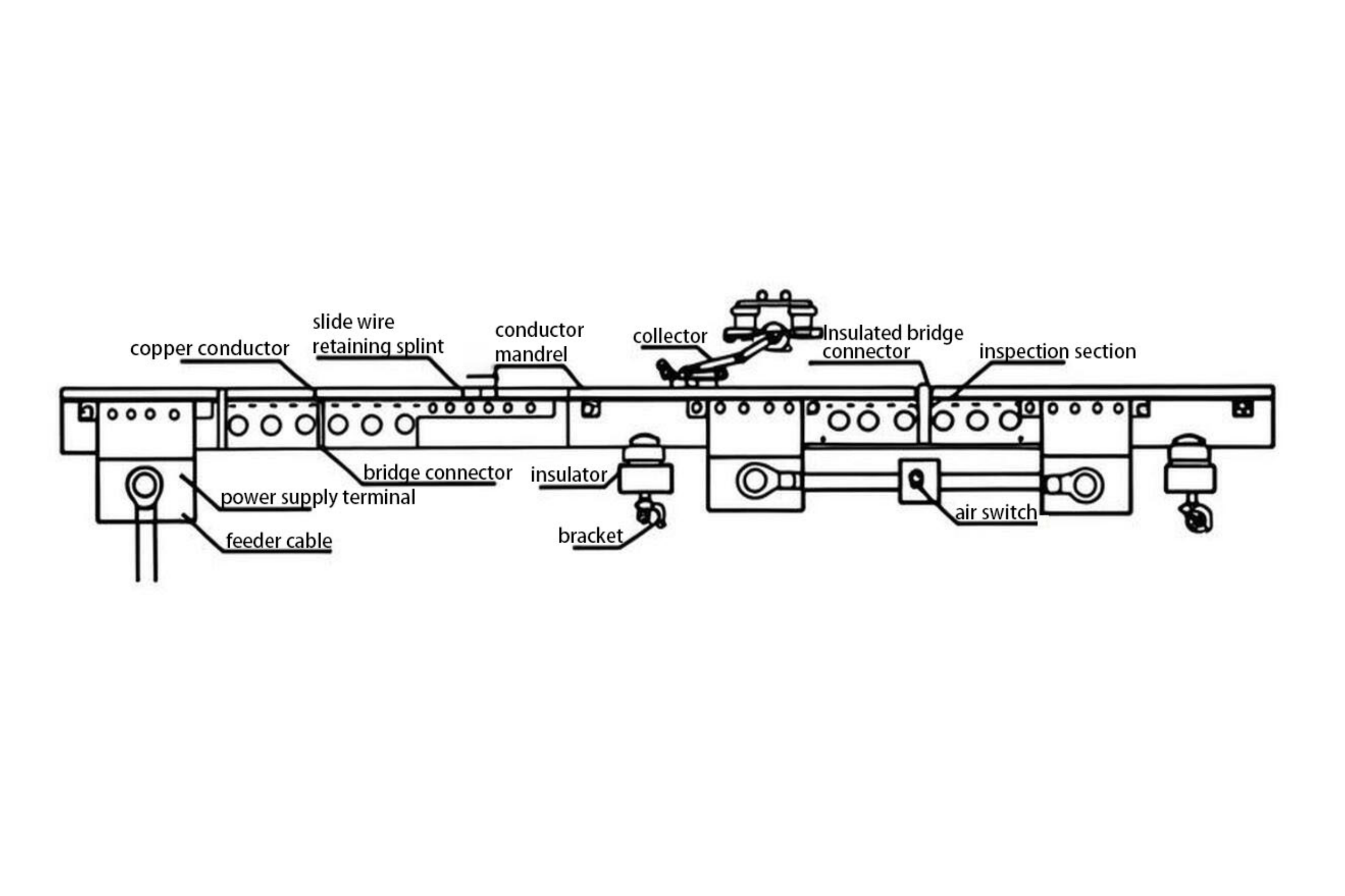

Copperhead conductor rails are typically made up of trapezoidal copper bars and channel steel, or “T”-shaped copper strips and channel-type aluminum, combined together. The working principle involves the conductor rails running through a duct, with the brush holder moving synchronously with the electrical device, transferring electrical energy to the motor or other control components.

This is a highly adaptable transmission device for electrical power, widely used in environments with high temperature, high humidity, high voltage, strong corrosion, and heavy dust, such as in steelmaking, metallurgy, and chemical industries.

Features

- Good contact performance: No arcing phenomenon, and no power interruptions or faults, ensuring reliable operation.

- Adaptable to harsh environments: Suitable for high temperature, high humidity, high voltage, strong corrosion, and heavy dust conditions.

- High mechanical strength and rigidity: Not easily bent or deformed, capable of withstanding large short-circuit impact currents without failure.

- Low electrical loss: Made with copper conductors or copper-aluminum profiles with low resistivity, significantly reducing energy loss in the conductors.

- High current carrying capacity: Copper conductors can handle currents up to 3000A or more.

- Reduced impedance with auxiliary cables: When auxiliary cables are added, the wire’s impedance can be reduced by multiples, forming a low-impedance busbar for broader applications.

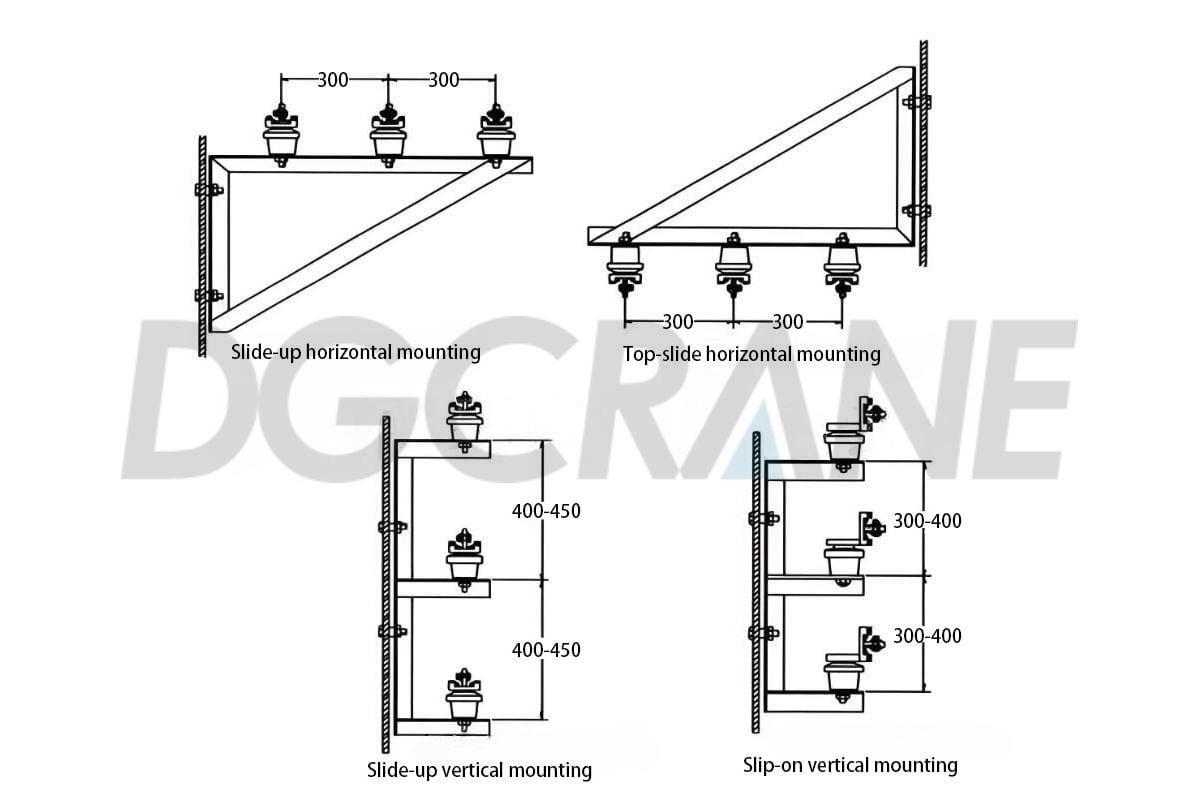

- Flexible wiring options: Can be mounted on the top, bottom, or side of the busbar.

- Excellent heat dissipation: The DMGH series high-temperature steel body busbar offers large heat dissipation area, low temperature rise, and long service life.

- Simple structure and easy installation: Available in three types: top pressure, side pressure, and bottom pressure.

- Convenient and quick maintenance and replacement: Saves time and labor, making it easier to maintain and replace components.

Electrical Characteristics

| Pollution Level | IV level (General conductive dust and condensation state) |

|---|---|

| Installation Level | Ⅲ level |

| Working Environment Humidity | ≤95% allowable short-term condensation |

| Working Environment Temperature | -45°C~+150℃ |

| Rated Working Voltage (V) | AC:660V~6000V(50~60HZ) |

| Rated Working Current (A) | 400A~4000A |

| Dielectric Strength of Insulation | AC(50~60HZ)40000V;1min, no breakdown or flashing phenomenon |

| Collector Running Speed (U) | V≤360m/min |

| Installation Altitude | ≤1000m |

| Insulation Resistance Between Poles and Between Pole and Ground | ≥10MQ |

| Short-Time Withstand Current | 20 times le/1s |

| Seismic Intensity Resistance | 8 level |

Specification

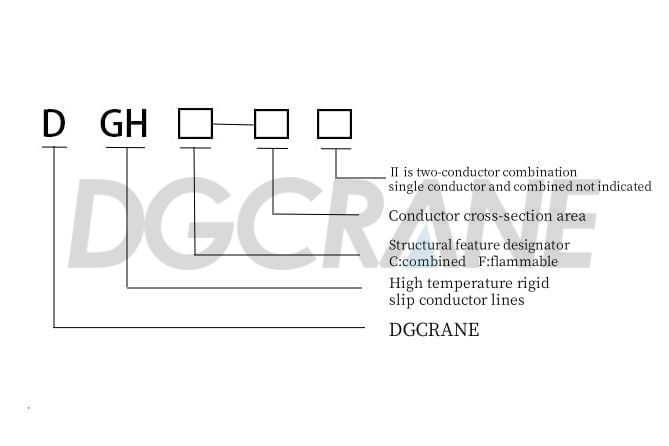

| Number | Model | Conductor Cross-Section Area (mm²) | Rated Current (A) |

|---|---|---|---|

| 1 | DGHC-140 | 140 | 500 |

| 2 | DGHC-160 | 160 | 600 |

| 3 | DGHC-230 | 230 | 800 |

| 4 | DGHC-265 | 265 | 1000 |

| 5 | DGHC-320 | 320 | 1200 |

| 6 | DGHC-465 | 465 | 1600 |

| 7 | DGHC-200Ⅱ | 200×2 | 1500 |

| 8 | DGHC-270Ⅱ | 270×2 | 2000 |

| 9 | DGHF-150 | 150 | 500 |

| 10 | DGHF-200 | 200 | 700 |

| 11 | DGHC-340Ⅱ | 340×2 | 2500 |

| 12 | DGHC-465Ⅱ | 465×2 | 3200 |

| 13 | DGHF-250 | 250 | 950 |

| 14 | DGHF-290 | 290 | 1100 |

| 15 | DGHF-375 | 375 | 1400 |

| 16 | DGHF-465 | 465 | 1600 |

| 17 | DGHF-500 | 500 | 1800 |

| 18 | DGHF-600 | 600 | 2100 |

| 19 | DGHF-700 | 700 | 2400 |

| 20 | DGHF-860 | 860 | 2800 |

Mounting

Application

Copperhead Conductor Rails perform excellently in harsh environments, providing reliable power transmission for cranes and heavy equipment while reducing maintenance costs. In addition, we offer enclosed conductor rails, seamless conductor rails, and single-pole insulated conductor rails to fulfill all your requirements.

Whether you are looking for enhanced durability, superior conductivity, or tailored performance, we are here to provide the ideal solution. Don’t hesitate to reach out for a personalized consultation – we’re happy to assist you in finding the perfect system for your specific needs.