Container Gantry Cranes (RMG)

Equipped with the special container spreader, and suitable for lifting international standard containers(20', 40', 45' containers).

Advanced performance, high production efficiency, good maneuverability, wide range of applications and low sensitivity to ground inequality.

- Capacity: 30t-60t

- Span length: 20-40m

- Lifting height: 9m-18m

- Work duty: A6-A8

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -25℃~+40℃, relative humidity ≤85%

- Crane control mode: Cabin control

- Reference Price Range:$10000-600000/set

Overview

Rail type container gantry crane (RMG) is designed and manufactured in accordance with national and industry standards such as GB/T3811 “Crane Design Specification” and GB/T14406 “General Gantry Cranes”.

U-shaped gantry cranes are widely used in open fields such as large-tonnage wharf heavy cargo and container berth terminal front loading and unloading ships and cargo loading and unloading, transportation, and stacking operations in the front yard.

The crane is track type, double cantilever, gantry adopts U-shaped support legs, the upper part of the hoisting trolley rotates, and the container spreader adopts electric telescopic spreader.

Advantages

- Compact Structure

- Good Rigidity

- Safety and Reliablity

- Advanced performance

- Covenient Installation

- Easy Transportation

Components

The gantry frame is the main body of the crane and the main force-bearing component. It is composed of main beams, support legs, end beams, lower beams, cab, walking platform, railings, ladders, and other auxiliary metal structures. It has sufficient strength, rigidity and stability. The main components are provided with lifting lugs and lifting holes for lifting, such as metal structures such as main beams, support legs, and trolley frames.

It is composed of the trolley frame, the lifting mechanism, and the trolley running mechanism. The trolley main frame is the box-shaped welded structure, and it is equipped with an integrated trolley rain shed. The frame is also equipped with safety devices such as stoppers, rail clearers, buffers, and operating limits.The lifting mechanism is equipped with the lifting weight limiter, the weight display function, and a variety of safety protection interlock switches. The wheel diameter and material are selected according to the maximum supporting force of the wheel under the most unfavorable conditions to ensure that some wheels will not be overloaded.

It is composed of three parts: the traveling support device, the driving device and the safety device. The design of the walking mechanism should ensure that the wheel pressures of the wheels under the same support legs are equal. The trolley is an articulated balanced beam structure to ensure uniform force on each running wheel. One driving device only drives one driving wheel, without open gear transmission. Equipped with wind-proof anchoring device, track cleaner, and polyurethane buffer. Wheel shaft break protection is installed between every two traveling wheels.

It can be directly connected to the trolley to move together via a special rigid support, avoiding collisions with stacks and spreaders.

Adopt enclosed, toughened glass (heat preservation type). Its structural design not only considers various functional requirements, it is durable, safe and reliable, but also considers a good view, comfortable and beautiful, so that the driver feels comfortable during operation.

Crane power supply: high-voltage cable reel power supply

Trolley conductive: towline power supply

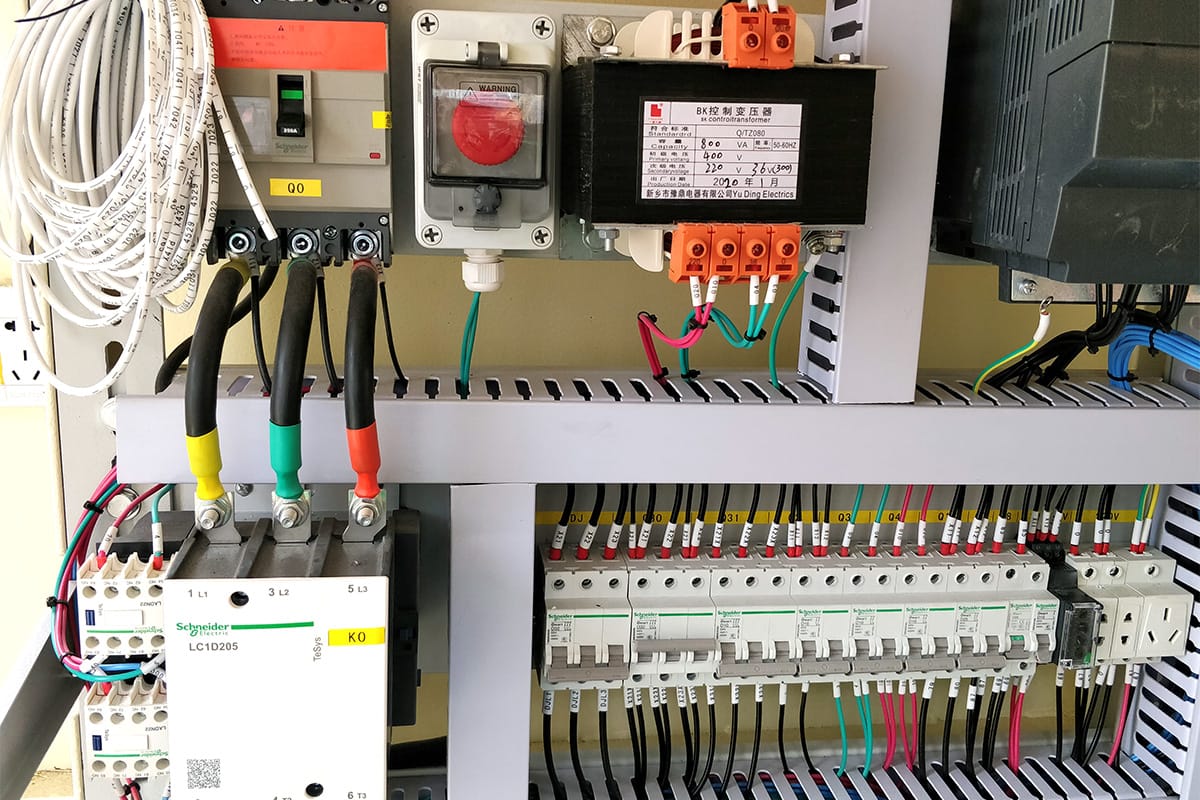

The power distribution system is composed of main circuit breaker, main power contact and overcurrent protection;

Protection devices include short-circuit protection, over-current protection, loss-of-voltage protection, zero protection, ascending limit protection, stroke limit protection, emergency power-off protection, electrical interlocking protection device, overload load limiter, warning bell, anemometer and Lightning rod, etc.

The main metal structural parts are connected by high-strength bolts. The attached steel structure is composed of ladders, platforms, and walkway railings, etc.

Ladder steps or platforms use checkered plates with a thickness of 3mm (or use galvanized steel gratings).

The spreader is determined according to the type of the container to be lifted, and the structure of the spreader requires easy replacement. The hydraulic power station is located on the spreader.

A Standard Double Girder Gantry Crane Will Be Produced in 60 Days.

Incoming material sample inspection

Steel plate uncoiling, leveling and cutting

Fabrication of the gantry crane main beam

Fabrication of the gantry crane end beam

Fabrication of the gantry crane support leg

Fabrication of the gantry crane ground beam

Crane preassembly

Fabrication of trolley frame

Painting and storage

Tips:

Lead time of cranes with different voltage may be 10-15 days longer as electrical components need to be customized by our supplier.On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.