-

INDUSTRIES

-

Precast Concrete Plant

-

Steel Industry

-

Paper Industry

-

Waste to Energy and Biomass Industry

-

Power Industry

-

Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

-

Port Machines Industry

-

Manufacturing Industry

-

Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

-

Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

-

Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

-

Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

-

Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

-

-

EQUIPMENT

-

Overhead Cranes

-

Single Girder Overhead Crane

-

Double Girder Overhead Crane

-

Underslung Cranes

-

Workstation Overhead Cranes

-

Low Headroom Overhead Cranes

-

Grab Bucket Overhead Crane

-

Electromagnetic Overhead Cranes with Lifting Magnet

-

Electromagnetic Overhead Cranes with Magnet Beam

-

Manual Overhead Cranes

-

Double Trolley Overhead Cranes

-

LDP Single Girder Overhead Cranes

-

- Eot Cranes

- Gantry Cranes

- Jib Cranes

- FEM Standard Crane & Hoist

- Hoist & Winch Trolley

- Light Cranes

- Explosion Proof Cranes and Hoists

-

Special Cranes

-

35-65t Clamp Overhead Crane

-

Boat Hoists

-

Boat Jib Crane

-

Yacht Davit Crane

-

Rail Mounted Container Gantry Crane

-

Cleanroom Overhead Cranes

-

YZ Ladle Handling Cranes

-

LDY Metallurgical Single Girder Crane

-

Charging Cranes for Steel Production

-

Insulated Overhead Cranes

-

Gantry Crane for Subway and Metro Construction

-

Forging Crane

-

Quenching Overhead Crane

-

Baking Multifunctional Crane

-

- Port Cranes

- Electric Transfer Carts

-

Overhead Cranes

-

CRANE PARTS

- Crane Wheel Range

- Crane Spreader

- Crane Drives

-

Crane Electrical Equipment

-

Overload Limiter

-

Crane Cabin

-

Crane Power Supply System

-

Explosion Proof Crane Radio Remote Controls

-

Joystick Type Crane Radio Remote Controls

-

Pushbutton Type Crane Wireless Remote Controls

-

Single-pole Insulated Conductor Rails

-

Enclosed Conductor Rails

-

Seamless Conductor Rails

-

Copperhead Conductor Rails

-

Overhead Crane Cables

-

- Other Cranes Parts

\

- ABOUT US

- CONTACT US

Crane Manufacturer and Exporter

- 10+ Years of Crane Export Experience

- Cranes Are Sold To 120+ Countries

- A Technical Team of 50+ People

- 3000+ Cases in Various Industries

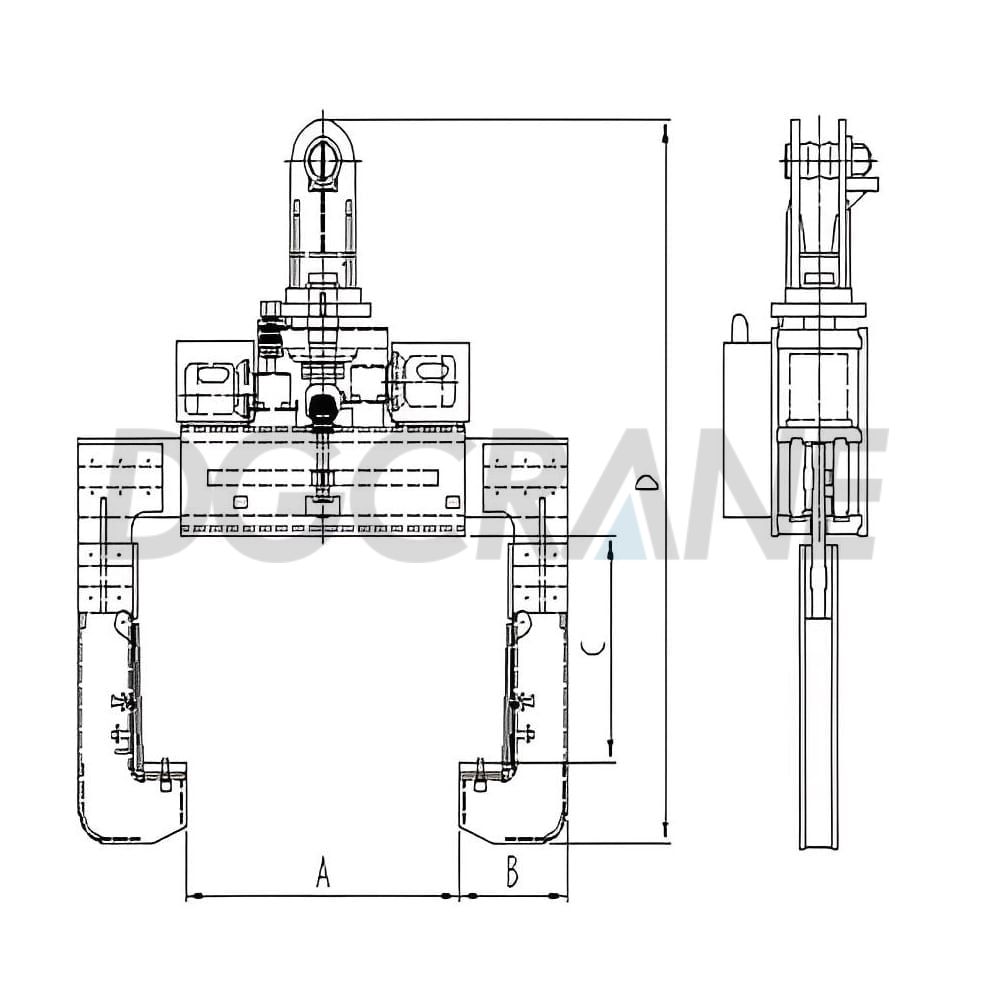

Coil Tongs

Electric coil steel clamp is a kind of hoisting equipment powered by electrical energy, which is mainly used for hoisting and handling steel coil items.

It has the advantages of easy operation, safety and reliability, high efficiency and energy saving, and is widely used in various fields such as ports, logistics, cold-rolled sheet production workshops of steel products enterprises, storage and transportation warehouses, etc.

Electric steel coil lifting tongs are mainly composed of electric motors, reducers, electrical control systems, gear transmission systems, etc.

Electric steel coil clamps are divided into electric horizontal coil hoisting tools and electric vertical coil hoisting tools according to the different placement and hoisting directions of steel coils.

The electric steel coil clamp is equipped with an independent remote control system. In the same workshop, multiple spreaders are used at the same time, and the remote controls do not interfere with each other.

Equipped with two sets of independent transmission systems, the upper transmission system can rotate the hook body horizontally by +90° or -255°, the lower transmission system controls the size of the opening of the hook body, and the hook body is equipped with touch-stop devices on both sides, which can reduce the hard extrusion of the steel coil. When the two sets of transmission systems are operated by the remote control, the button switches can be interlocked.

The load-bearing parts are all made of alloy steel, which ensures that the spreader has a long enough service life.

Coil Lifter is equipped with a lubrication system, and an oil-containing tank is milled in the lower groove of the sliding beam for lubrication when the sliding beam is retracted.The gearboxes of the upper and lower transmission are equipped with oil holes and oil labels, and the gear transmission adopts manual addition of grease.

Parameter

| Main dimensions (t) Loading | A | B | C | D | weight (t) |

|---|---|---|---|---|---|

| 15 | 450-1600 | 450 | 800 | 2500 | 2300 |

| 20 | 450-1750 | 500 | 800 | 2600 | 2800 |

| 30 | 450-2100 | 500 | 850 | 2700 | 3000 |

| 40 | 650-2200 | 500 | 900 | 2750 | 4000 |

case

Fill Out Your Details and We Will Get Back to You Within 24 Hours!

Subscribe to our newsletter

The latest DGCRANE price list, news, articles, and resources.

- Overhead Cranes

- Low Headroom Overhead Cranes

- Double Girder Overhead Crane

- Grab Bucket Overhead Crane

- Top Running Overhead Crane: Wide Application and Easy Maintenance

- Coker Cranes for Harsh Environments: High Temperature and Corrosion Resistant Design

- Overhead Cranes for Concrete Pile Precast Workshop: Versatile Solutions for Demanding Operations

- Single Girder Overhead Cranes

- Eot Cranes

- Single Girder Eot Cranes

- Double Girder Eot Cranes

- Underslung Cranes

- Light Cranes

- Adjustable Gantry Cranes: Easy to Move, Safe, and Space-Efficient

- Foldable Aluminum Gantry Crane: Lightweight, Strong, and Portable

- Freestanding Workstation Bridge Crane: Lightweight, Modular and Adaptable Material Handling Solution

- Ceiling Mounted Workstation Bridge Crane: Ideal for Tight Spaces and Complex Layouts

- Multi-point Suspension Cranes: Suitable for Large-Span Industrial Workshop

- Workstation Overhead Cranes

- Monorail Overhead Cranes

- Workstation Jib Cranes

- Electric Hoists

- Gantry Cranes

- Shipyard Gantry Cranes: Specialized Lifting Solutions for Shipyard Operations

- Truss Gantry Cranes: Cost-Effective, Wind-Resistant, and Perfect for Large Spans

- FEM Double Girder Gantry Crane with Open Winch: European Performance, 20% Cost Saving

- Different Types of Small Portable Aluminium Gantry Cranes: Cost Effective

- Single Girder Gantry Cranes

- Double Girder Gantry Cranes

- Semi Gantry Cranes

- Casting Yard Gantry Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Portable Mobile Gantry Cranes: Flexible, Movable and Space-Saving

- FEM Standard Crane & Hoist

- FEM Standard Overhead Cranes

- FEM Standard Gantry Cranes

- FEM Standard Jib Cranes

- FEM Standard Wire Rope Electric Hoists

- FEM Standard Electric Chain Hoists

- Hoist & Winch Trolley

- Low Headroom Wire Rope Electric Hoist: Compact Design for Efficient Lifting in Tight Spaces

- Electric Hoist for Molten Metal: High-Temperature, Safe Lifting for Metallurgical Environments

- Pneumatic (Air) Chain Hoists: Ideal for Explosion-Proof Environments

- Lever Hoists: Compact, Versatile Manual Lifting Tool

- Galvanizing & Pickling Electric Hoist for Harsh Environments

- 6 Double Girder Trolley Electric Hoists for Overhead Cranes: Custom Solutions for Every Lifting Need

- Manual Chain Hoists: Alloy Steel Construction for Smooth and Safe Lifting

- Electric Wire Rope Hoists

- Chain Hoists

- Crane Trolley

- Electric Winch

- Explosion Proof Cranes and Hoists

- Explosion Proof Single Girder Overhead Cranes: Safe Lifting Solution for Hazardous Environments

- Explosion Proof Wire Rope Electric Hoist: Upgrade Your Safe

- Explosion Proof Electric Chain Hoist of High Qualit

- Explosion Proof Manual Chain Hoist: Safety in Every Lift

- Explosion Proof Double Girder Overhead Crane: More Cost Effective

- Port Cranes

- Rubber Tyred Container Gantry Crane

- Ship To Shore Crane

- Container Straddle Carrier

- Harbour Portal Crane

- Shipyard Portal Cranes

- Container Gantry Cranes: RTG & RMG Solutions for Ports and Terminals

- Reliable Versatile Electric Transfer Carts

- AGV Transfer Carts

- Powerful Heavy Duty Coil Transfer Carts

- RGV Transfer Carts

- Powerful Pallet Transfer Carts

- Trackless Transfer Carts

- Reliable Heavy Duty Ladle Transfer Cars

- Superior Die Transfer Carts

- Rail Transfer Carts

CRANE PARTS

- Insulated Overhead Cranes for Safe Non-Ferrous Metal Smelting

- Automated Bulk Grab Overhead Crane: Efficient Ore, Coal, Sand, and Slag Handling

- Electrolytic Copper Cranes: Cathode and Anode Handling in Copper Electrolysis Lines

- Pot Tending Machine: Specialized Equipment for Electrolytic Aluminum Production

- Anode Carbon Block Stacking Overhead Crane for Aluminum Electrolysis Plants

- Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

- Heavy Duty Forging Cranes: Durable, High-Capacity Solutions for Forging

- Quenching Overhead Crane for Heat Treatment Plant: High-Temperature Insulated and Efficient Lifting Solution

- Gantry Crane for Subway and Metro Construction: Efficient Tunnel Debris Removal Solutions

- Charging Cranes for Steel Production: Safe and Reliable Solutions for Efficient Material Handling

- Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

- Rail Mounted Container Gantry Crane

- Special Cranes

- 35-65t Clamp Overhead Crane

- Boat Jib Crane

- Yacht Davit Crane

- Boat Hoists

INDUSTRIES

- Steel Industry

- Paper Industry

- Power Industry

- Overhead Cranes for Automotive Production: Smart Solutions for Enhanced Efficiency

- Port Machines Industry

- Manufacturing Industry

- Overhead Cranes for Timber Lifting: Efficient and Safe Wood Handling

- Overhead Cranes for the Aviation Industry: Streamlining Aircraft Assembly, Maintenance, and Repair

- Overhead Cranes for Food and Beverages: Ideal for improving productivity and food safety

- Overhead Cranes for Aerospace Industry: Key Role in Efficient Rocket Manufacturing and Launch

- Precast Concrete Plant

- Waste to Energy and Biomass Industry

- Different Types of Container Cranes, Shipyard Cranes, Cargo Cranes Used in Port, Harbor and Quay

COMPANY

- sales@dgcrane.com

- +86 373 387 6188

- +86 189 3735 0200

- Floor 30,Gongyuan INT'I Building, Jinsui Road, Xinxiang City, Henan Province, China