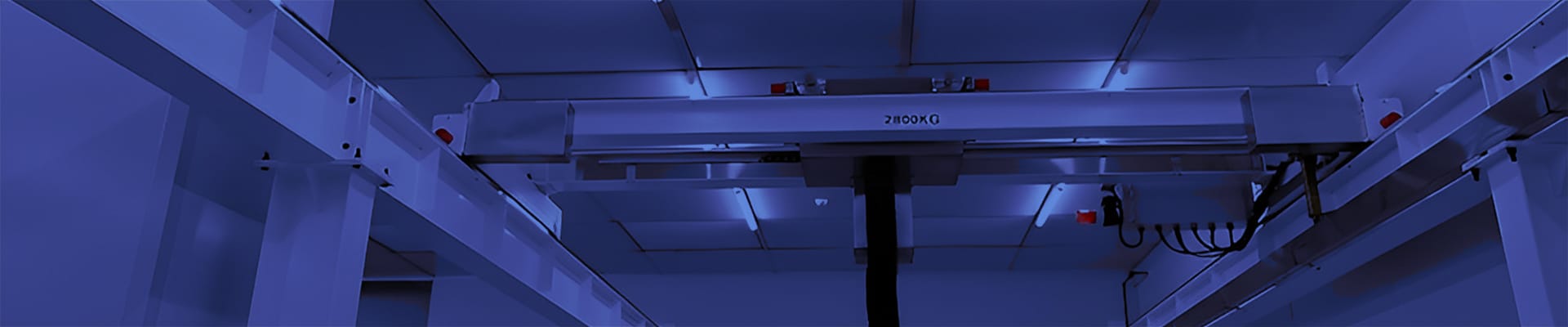

Cleanroom Overhead Cranes: Reliable Solutions for Healthcare, Electronics, and GMP Workshops

Cleanroom overhead cranes are designed, manufactured, installed, commissioned, operated, and maintained specifically to meet the air purification requirements in controlled environments. These cranes are primarily used for material handling, lifting, and transporting within cleanroom environments, ensuring contamination-free operations during the loading and unloading of precision instruments, components, and other products.

Types of Cleanroom Cranes

Cleanroom Overhead Cranes

The cleanroom overhead crane is made from high-quality materials with a dust-free design, preventing particles from contaminating the production process and ensuring air purity meets industry standards. Its compact structure and precise operation suit various cleanliness levels, and it can be customized to meet specific customer needs, making it ideal for cleanroom material handling.

Cleanroom Jib Cranes

Made from stainless steel or specially coated materials to prevent dust and particle accumulation, these cranes feature advanced control systems for smooth and precise operations. With a compact structure and minimal space requirements, they are ideal for efficient material handling in confined spaces. Their easy-to-clean and maintain design makes them a top choice for cleanroom environments.

Cleanroom Portable Gantry Cranes

Specifically designed for high-standard cleanrooms, these gantries are constructed from high-strength stainless steel or aluminum alloy, ensuring a sturdy yet lightweight structure. The unique swivel wheel design allows for 360-degree maneuverability, making them adaptable to various space configurations. The gantry's polished surface effectively prevents dust accumulation.

Cleanroom Gantry Cranes

Utilizing advanced contamination-free technologies and materials, these gantry cranes ensure dust-free and contamination-free handling processes. The crane offers superior performance and stability, meeting the stringent requirements of cleanroom operations. Cleanroom gantry cranes are equipped with intelligent control systems for remote monitoring and diagnostics, enhancing production efficiency and reliability.

With their specialized design and manufacturing, these cranes effectively prevent the introduction of foreign objects and particles, ensuring that the cleanroom's air purity meets specific requirements.

Cleanroom Crane Cleanliness Levels

The cleanliness level of the cleanroom overhead crane is determined by the specific application environment, such as Class 100, Class 1,000, Class 10,000, or Class 100,000, which represent the number of allowable airborne particles within the cleanroom. The higher the cleanliness level, the stricter the control over airborne particle contamination.

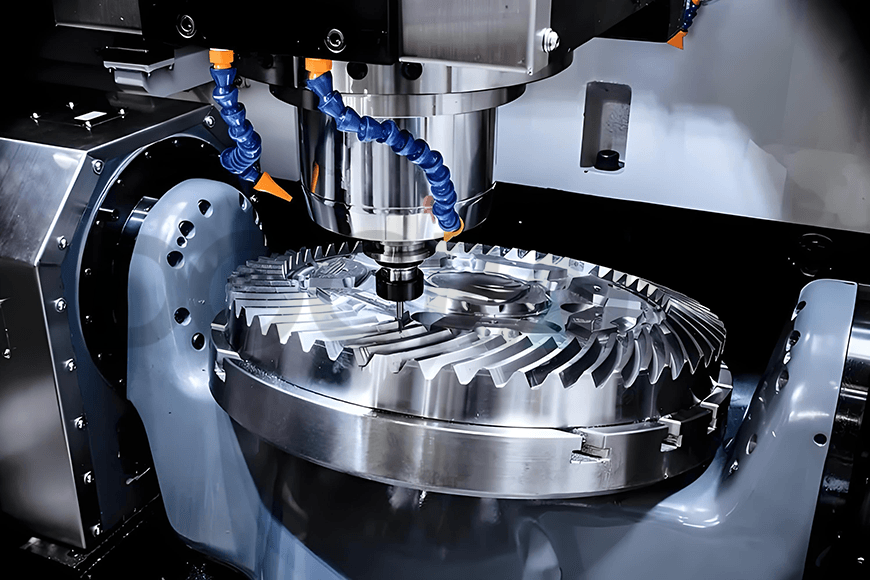

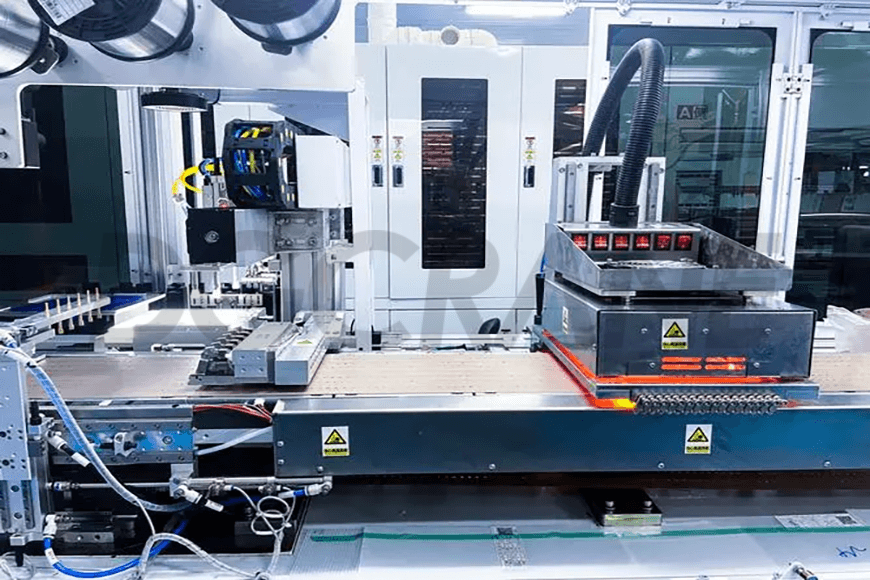

Industry Applications

Key Features of Cleanroom Overhead Cranes

- Sealed Structure: The cleanroom overhead crane is housed in a sealed room structure, including walls, ceilings, and floors, to prevent external contaminants from entering.

- External Filtration: External filtration systems, including fans and filters, remove dust and impurities from incoming air, ensuring clean air enters the cleanroom.

- Internal Filtration: Inside the cleanroom, air purifiers and high-efficiency filters are installed to further clean and filter airborne particles.

- Purification Control: A purification control system monitors and regulates indoor air quality, ensuring the concentration of airborne particles remains within defined limits.

Advantages of Cleanroom Overhead Cranes

- Excellent Cleanliness Performance: Utilizing corrosion-resistant, easy-to-clean materials, and dust-sealed designs, cleanroom overhead cranes ensure stable operation in contamination-free environments over long periods.

- Precision Control: Featuring advanced variable frequency drives or PLC control technology, cleanroom overhead cranes offer precise control and easy operation. Safety features such as overload protection and limit switches ensure safe usage.

- Energy Efficiency: The drive systems use high-efficiency motors and energy-saving technologies, ensuring low power consumption and reduced energy costs. Additionally, the fast operating speed enhances productivity.

- High Stability: The crane’s structure, made from customized materials and advanced manufacturing processes, ensures strong performance, even under heavy loads and high-speed conditions.

Maintenance and Care

To ensure the long-term performance and lifespan of cleanroom overhead cranes, regular maintenance and servicing are essential. This includes inspecting all components for wear, cleaning the crane's surface and internal parts, and replacing worn parts. It is also important to regularly check and maintain the air purification systems to ensure the cleanroom's air remains uncontaminated.

Our cleanroom cranes offer exceptional quality and reliable performance, specially designed for dust-free environments. We also provide customizable solutions to meet your specific requirements.

If you’re looking for a high-performance crane for your cleanroom, feel free to contact our expert team for more information and start customizing your ideal equipment today.