Casting Yard Gantry Cranes

It is used for the beam lifting in precasting plant, bridges transporting and bridges erecting, etc with the special spreader.

Compared with ordinary gantry cranes, installation and disassembly are convenient and quick, economical and practical.

- Capacity: 20t-900t

- Span length: 24-55m

- Lifting height: 9m-60m

- Work duty: A3

- Raged voltage: 220V~690V, 50-60Hz, 3ph AC

- Work environment temperature: -25℃~+40℃, relative humidity ≤85%

- Crane control mode: Cabin control

- Reference Price Range: $10000-600000/set

Overview

Precasting(Engineering) gantry crane is designed and manufactured in accordance with national and industry standards such as GB/T3811 “Crane Design Specification” and GB/T14406 “General Gantry Crane”. It is suitable for places such as highways, bridge beam yards and bridge erection. The retrieval devices can be hooks, spreaders and pin-type movable pulleys. The gantry crane frame is A type with Rigid leg and flexible leg support structure, which increases the overall flexibility and improves the carrying capacity of the gantry frame.

Due to the smaller wind-receiving area than the box type structure, the truss-type structure is mainly used in outdoor places with large wind loads

The crane is composed of the steel structure, the trolley, the crane traveling mechanism, and the electrical system, etc.

Advantages

- Good Rigidity

- Safety and Reliablity

- Advanced performance

- Easy Installation

- Easy installation and transportation

- Economical and practical

Introduction

Casting yard gantry crane is widely used in casting yard of railway and bridge construction. This gantry crane performances mainly during concrete girders’ fabrication and transportation. Considering casting yard is usually in open site and has a large area, crane dimension and power supply should be taken into consideration. In following cases, we will explain in details in order to give you a general pics.

One client from Middle East asks for double girder gantry crane for concrete girders handling in casting yard. Max.self-weight of the girder is 120 ton and length is 24 m. considering safety is the first priority, our technician suggest using 2 sets of 70 ton gantry cranes synchronized running. In this way, the two cranes can work together to move the concrete girders and also runs independently if needed.

Besides, we also add fuel generator to the cranes because the casting yard is usually in country side and there is no electric facility available.

Another client asks for 2 sets of 30+30 ton gantry cranes for his casting yard. They requires the two cranes can be synchronized running, and what’s more, they also requires four trolleys synchronized running.

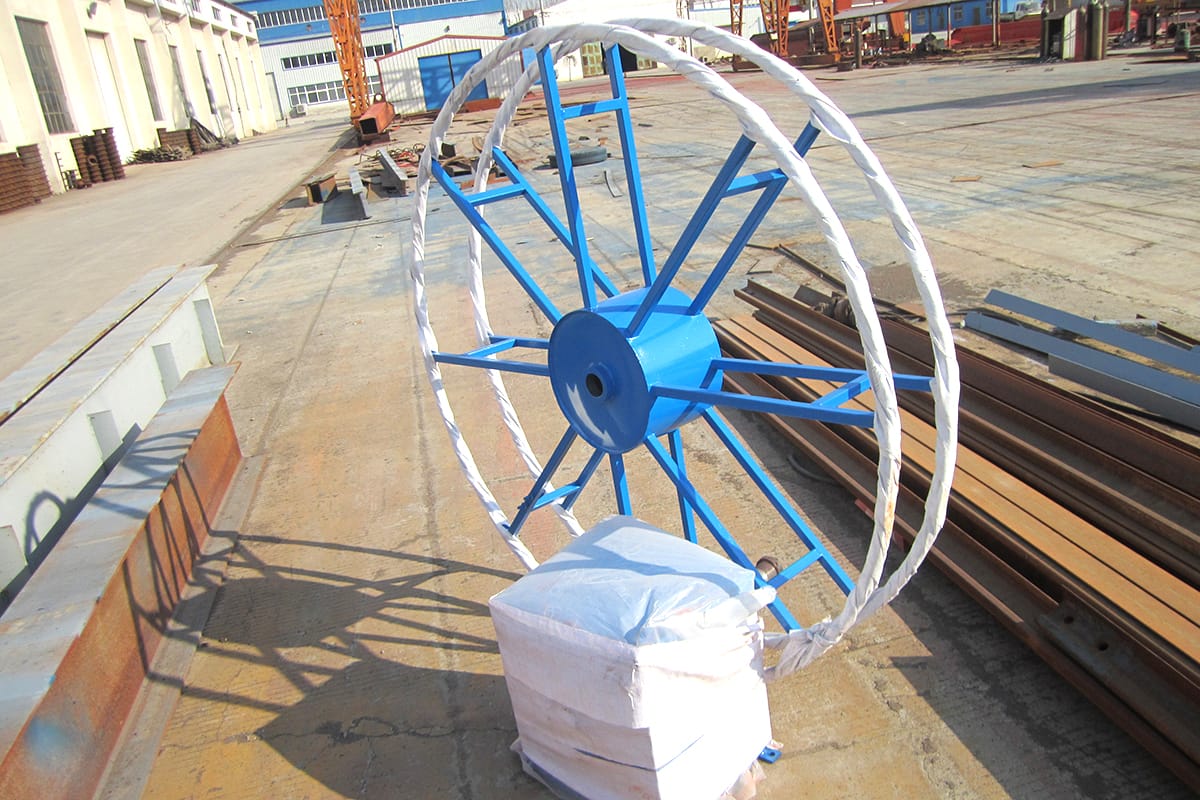

During the details discussion on the crane solution, our engineers also offer detailed design of rail foundation so the client can easily proceed the rail foundation. And as for the power supply, our engineers suggest cable reel to save the cost.

We also supply technical support during crane assembling and commissioning, our technicians will go to the site from the very beginning to the commissioning successfully finished.

Components

It is composed of main beams, support legs, connecting frames, connecting beams, trolley running rails, walking platforms, railings, ladders and other auxiliary metal structures. The support legs adopts a set of rigid legs and a set of flexible legs.

The main beam, the connecting beam, the support legs and the connecting frame are connected together by high-strength bolts and pins. The simple truss structure door frame has light overall weight and small windward area, which can effectively reduce the wind load.

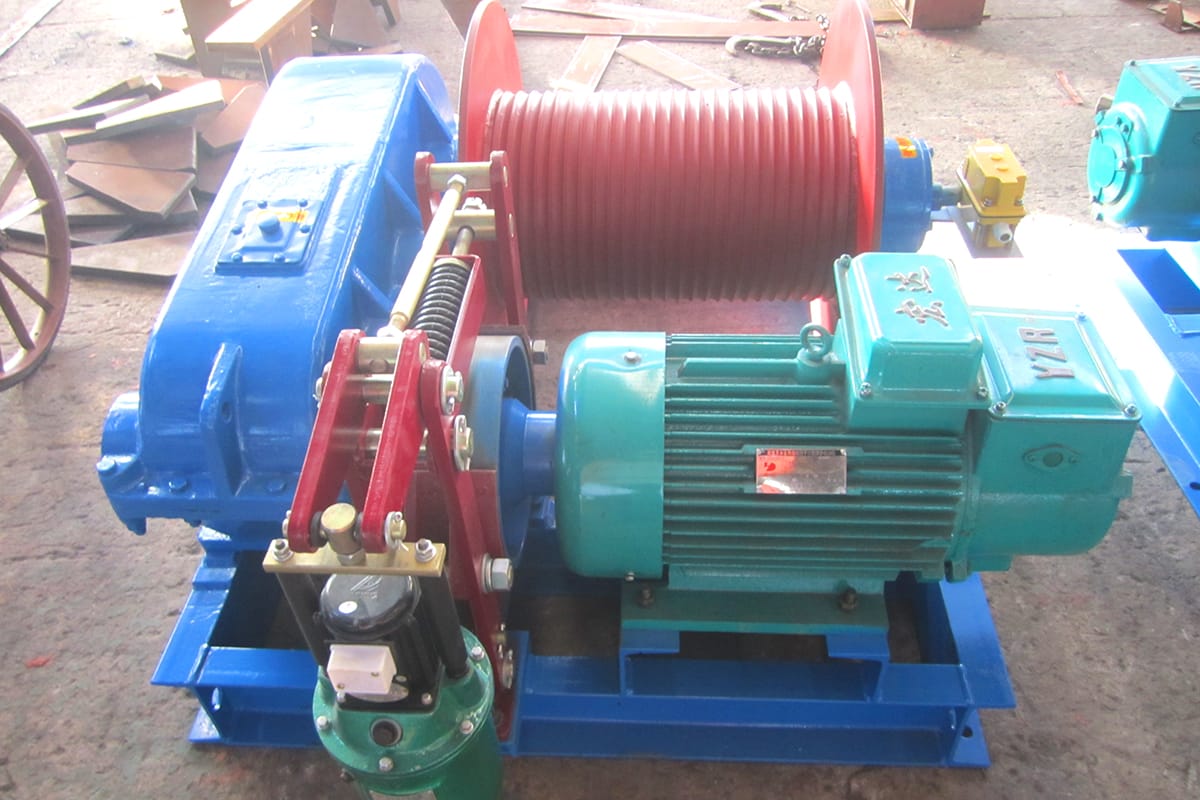

It is mainly composed of the hoisting mechanism (JM winch), the trolley frame and the trolley running mechanism. The JM electric winch is composed of the motor, the coupling, the brake, the reducer and the drum, which are installed on the frame together.

The trolley frame is a combined structure of plate and section steel welded together, which has sufficient strength and rigidity to ensure that the trolley frame will not affect the normal operation of each mechanism after being deformed under load. The trolley adopts a sealed rain cover, and the rain cover has lighting measures.

If required by the customer, an electric hoist (as a secondary lifting mechanism) can be used for small lifting.

It is composed of the motor, the reducer, and the wheel set,etc. The wheel drive shaft is directly connected to the low-speed end of the reducer (or is connected by a coupling). This structure is conducive to the installation, maintenance and disassembly of the wheel device.

The entire crane driving device has simple structure, low noise, generous appearance, safe and reliable use, and convenient installation and maintenance.

Angle box wheel set is adopted, the crane wheels are double-rim wheels, the trolley wheels are single-rim wheels, the wheel material is ZG340-640, the treads of the wheels are heat treated, the hardness range is HB330-380, and the quenching depth of the crane wheels is not less than 20mm, the quenching depth of the trolley wheel is not less than 15mm, and the hardness at the quenching depth is not less than HB260.

It is equipped with rail clamps, anchoring devices, buffers, and rail sweepers;

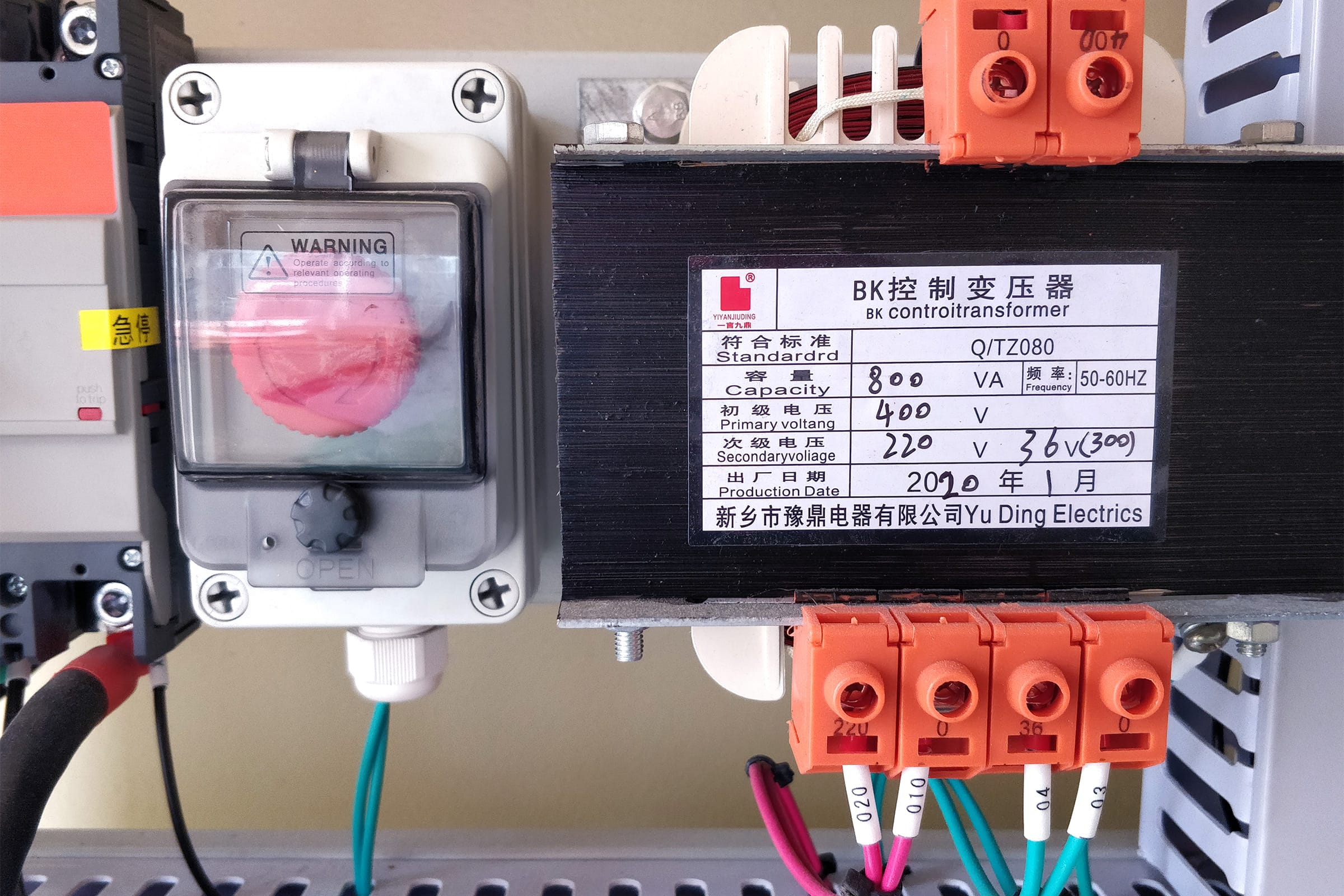

The power distribution system is composed of main circuit breaker, main power contact and overcurrent protection;

Protection devices include short-circuit protection, over-current protection, loss of voltage protection, zero protection, ascending limit protection, travel limit protection, overload load limiter, emergency power-off protection, trolley sound and light alarm, electrical interlock protection device,etc.

Crane power supply: trolley wire or cable drum;

Trolley conductive: mobile cable trolley.

Safe and reliable ladders, platforms and walkways are provided where operation, inspection, and maintenance are required, and there is sufficient working space. The ladder and platform are formed by bending steel pipes and angle steels. The platform is covered with non-slip patterned steel plates, and the bottom of the platform is equipped with a protective plate.

It is set on rigid legs. The driver’s cab is the working place where the operator controls the crane. It adopts a closed driver’s cab. Its structural type design not only considers various functional requirements, sturdiness, durability, safety and reliability, but also considers a good view, comfortable and beautiful, so that the driver feels comfortable during operation, and the layout of the driver’s interior fully reflects humanity and meets the needs of the demander.

A Standard Casting Yard Gantry Cranes Will Be Produced in 60 Days.

Incoming material sample inspection

Steel plate uncoiling, leveling and cutting

Fabrication of the gantry crane- main beam

Fabrication of the gantry crane-support leg

Fabrication of the gantry crane- ground beam

Crane preassembly

Fabrication of trolley frame

Painting and storage

Tips:

Lead time of cranes with different voltage may be 10-15 days longer as electrical components need to be customized by our supplier.On-Site Installation or Remote Instruction Is Available

Trust building is really hard, but with 10+ years of sales experience and 3000+ projects we've done, both end-users and agents have gained and benefited from our cooperation. By the way, Independent sales rep recruiting: Generous commission / Risk free.