Baking Multifunctional Crane: Furnace Tending Assembly for Efficient Carbon Roasting

The baking multifunctional crane is a specialized large and complex piece of equipment essential for the roasting production process. It integrates mechanical, transmission, pneumatic, environmental protection, intelligent, electrical control, and automation functions, operating as a smart mechanical arm for automated handling.

Suitable for environments with high carbon dust, hydrocarbons, asphalt fumes, and similar substances. Maximum ambient temperature is 55°C.

Functions

The baking multifunctional crane is designed specifically for carbon roasting operations and meets the following process requirements:

- Transport between the roasting and assembling/disassembling stations.

- Loading carbon blocks into the roasting furnace using fixtures from the assembly station, then unloading them at the disassembly station.

- Using suction devices from the material zone or furnace room to transfer materials into the furnace, or extract them back into the material zone and furnace for repeated cycles.

- The pneumatic conveying equipment uses suction pipes to extract high-temperature filling materials from the furnace, while simultaneously performing dust grading operations.

- Auxiliary electric hoists are used to handle other workshop equipment (such as combustion racks, blowing pipes, thermocouple racks, smoke racks, flue gas measurement racks, cooling racks, etc.) and miscellaneous lifting tasks.

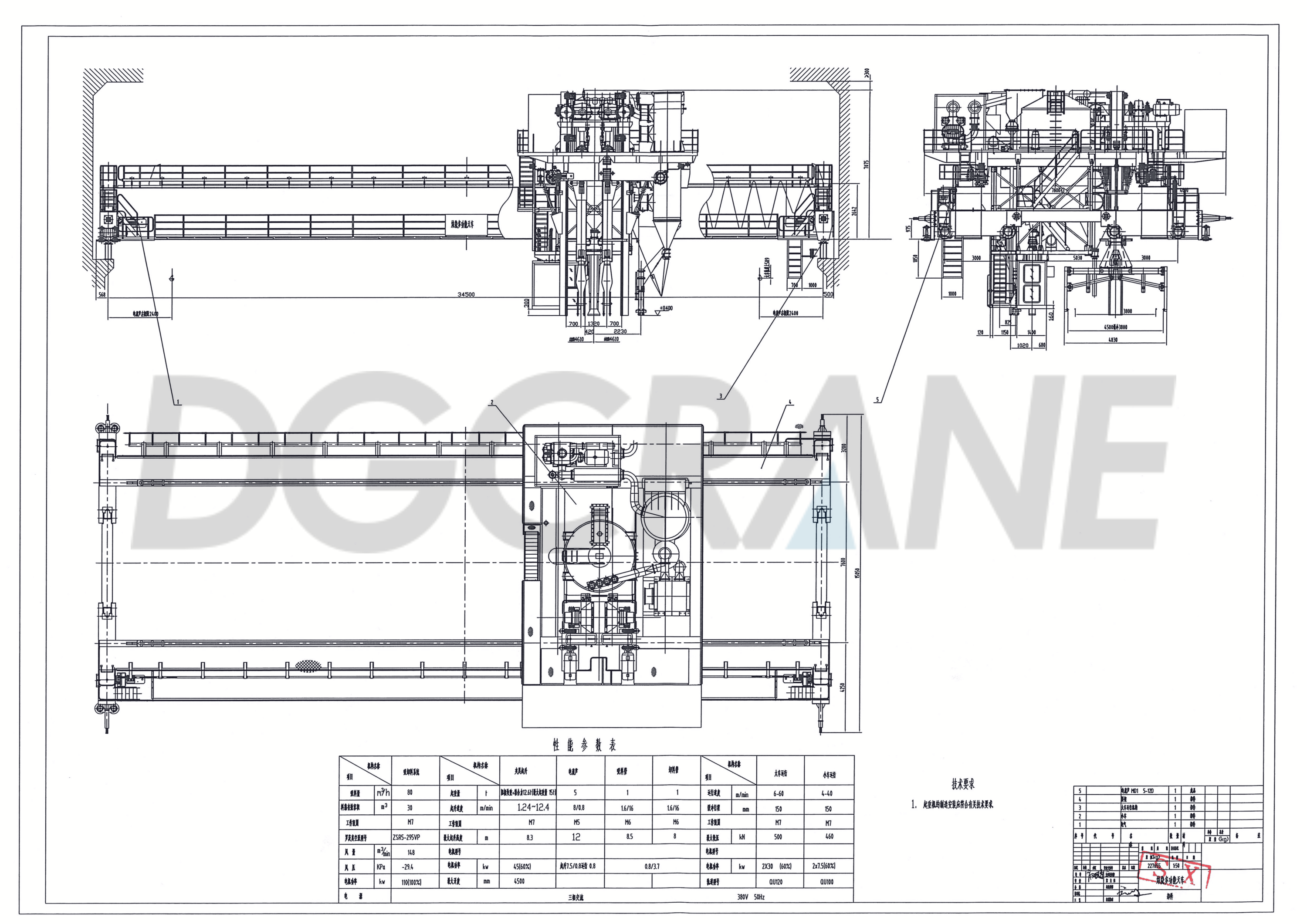

Components of the Unit

The baking multifunctional crane consists of three major parts:

- The Large Cart: The main bridge of the baking multifunctional crane, which can move along the longitudinal tracks of the workshop. It is equipped with a movable electric hoist to handle miscellaneous lifting tasks.

- The Small Cart: This is the core of the baking multifunctional crane. The main operating tools, control room, and electrical control system are all mounted on the small cart, which moves horizontally along the track on the top surface of the large cart.

- Electrical Control System: The PLC-based electrical control system is used, centralized on the control panel in the control room. A touch screen allows operators to monitor the status of electrical components, view fault locations and causes, and issue alarms. Wireless signal exchange devices are used to control the ground equipment.

Working Environment and Conditions

- Air Quality: The air contains carbon dust, hydrocarbons, smoke, and asphalt fumes.

- Ambient Temperature: The unit operates in environments with temperatures up to 55°C.

- Power Supply: AC 380V ± 10% (three-phase three-wire system); frequency AC 50Hz ± 2%.

- Operating Schedule: The baking multifunctional crane operates three shifts per day, with each shift lasting 8 hours continuously. Weekly maintenance time should not be less than 10 hours.

- Filling Material Humidity: The humidity of the filling material should be less than 5%. Higher humidity can cause damage to the filter bags.

Technical Parameters

| Baking Multifunctional Crane | Clamps Crane | Vacuum Loading and Unloading Crane | |

|---|---|---|---|

| Crane Span (m) | 34.5 | 34.5 | 34.5 |

| Trolley Crane Speed (m/min) | 2-60 | 2-60 | 2-60 |

| Travel Speed (m/min) | 1.6-40 | 1.6-40 | 1.6-40 |

| Clamp | |||

| Lifting Speed (m/min) | 2-10 | 2-10 | — |

| Lifting Travel (m) | 8.5 | 8.5 | — |

| Lifting Weight (t) | Dual Clamps with a capacity of 2×10 | Dual Clamps with a capacity of 2×10 | — |

| Opening (mm) | 5060 | 5060 | — |

| Speed Control | |||

| trolley crane | Variable Frequency Drive | Variable Frequency Drive | Variable Frequency Drive |

| Trolley | Variable Frequency Drive | Variable Frequency Drive | Variable Frequency Drive |

| Clamp | Variable Frequency Drive | Variable Frequency Drive | — |

| Vacuum Loading and Unloading Pipe | |||

| Lifting Speed (m/min) | 2.6/16 | — | 2.6/16 |

| Lifting Travel (m) | 9.7/9.7 | — | 9.7/9.7 |

| Loading/Unloading Capacity (t/h) | 65/80 | — | 65/80 |

| Material Box Volume (m3) | 45 | — | 45 |

| Vacuum Pump | |||

| Power (kW) | 160 | — | 160 |

| Wind Pressure (kPa) | -40 | — | -40 |

Case

Shandong Energy Roasting Workshop Suction Crane Case Study

Filling Material Conditions:

- Material: Calcined coke, metallurgical coke

- Particle Size: 1-6 mm

- Temperature of Discharged Filling Material: Normal ≤350°C (maximum 450°C)

- Bulk Density: ~0.8 t/m³

Workshop Environmental Parameters:

- Workshop Span: 36 m

- Workshop Length: 250 m

- Track Center Distance: 34.5 m

- Workshop Ground Elevation: ±0.000 m

- Furnace Top Elevation: 6.3 m

- Track Top Elevation: +13 m

- Workshop Roof Truss Under Elevation: 15.3 m

- Number of Roasting Furnace Chambers: 58 chambers per unit

- Number of Material Bins: 8 bins per chamber

- Number of Combustion Channels: 9 channels per chamber

- Number of Anode Layers per Bin: 3 layers

- Number of Anode Blocks per Layer: 7 blocks

- Dimensions of New Material Bins: 5700 mm (length) × 800 mm (width) × 6000 mm (depth)

- Center Distance Between Adjacent Bins: 1330 mm

- Charging Method: Side-loading, 3 layers, 7 blocks per layer

- Material Thickness at Bottom: 200 mm

- Distance from Outer Bin Center to Crane Track Center: 5.3 m

- Slide Line Side: 5.3 m

- Slide Line Opposite Side: 5.3 m

Main Technical Parameters of the Unit Equipment:

- Suction Capacity: 80 m³/h (related to production efficiency)

- Effective Volume of Material Bin: 30 m³

- Effective Volume of Dust Material Bin: 5 m³

- Filling Rate of Material: 100 m³/h (related to production efficiency)

- Work Grade: A8

- Large Cart Running Speed: 0-60 m/min (variable frequency control, 4 speed settings)

- Small Cart Running Speed: 0-40 m/min (variable frequency control, 4 speed settings)

- Suction/Discharge Pipe Lifting Speed: 2-12 m/min (variable frequency control, 2 speed settings)

Discover the unparalleled efficiency of DGCRANE’s Baking Multifunctional Crane—a perfect blend of superior quality, expert engineering, and tailored customization. Designed to meet the rigorous demands of industrial roasting operations, our crane features precise control systems, durable components, and flexible configurations to adapt to your unique needs. Trust DGCRANE for innovative solutions that ensure reliable performance, increased productivity, and long-lasting value. Experience the difference with a crane built for excellence!