10+ Years of Crane Export Experience

Providing customized solutions for crane design, production, packaging and transport.

Cranes Are Sold To 120+ Countries

Focusing on international projects, both end-to-end and partnership projects.

A Technical Team of 50+ People

Experienced technical team to help you solve all kinds of crane problems.

3000+ Cases in Various Industries

Including metallurgy, steel mill, prefabricated board factory, paper mill and other industries.

Rich Industrial Experiences

Focusing on Overseas Projects

- Canada (1)

- USA (5)

- Colombia (2)

- Peru (8)

- Brazil (6)

- Chile (2)

- Uruguay (2)

- Argentina (6)

- Australia (4)

- Singapore (4)

- Vietnam (4)

- Philippines (6)

- Bangladesh (10)

- South Africa (2)

- Zambia (2)

- Tanzania (4)

- Kenya (2)

- Nigeria (2)

- Ethiopia (2)

- Sri Lanka (5)

- Maldives (2)

- Qatar (8)

- Oman (3)

- Thailand (4)

- India (6)

- UAE (9)

- Pakistan (8)

- Iran (3)

- Kazakhstan (2)

- Mongolia (4)

- Finland (3)

- Sweden (2)

- Germany (2)

- Ukraine (3)

- Romania (2)

- Spain (3)

- Kuwait (6)

The Right Product Solution

Product Design Specifically for Export

Crane and Plant Integration Solutions Are Available

We don't just have cranes and other lifting products, we also offer a one-stop shop for custom steel buildings.

Adaptation to Special Plant Environments

We can meet the needs of factory environ-ments from -30 to 50 degrees Celsius, or for cranes with explosion-proof requirements.

Customized Voltage Supply

We can customize the generator to meet the different voltage requirements around the world, whether the voltage in your country is 100V~130V or 220~240V. Alternatively, generators are available.

Adequate Accessories

We are well equipped with spare parts that not only compress the production cycle and improve productivity, but also enable timely response in after-sales maintenance.

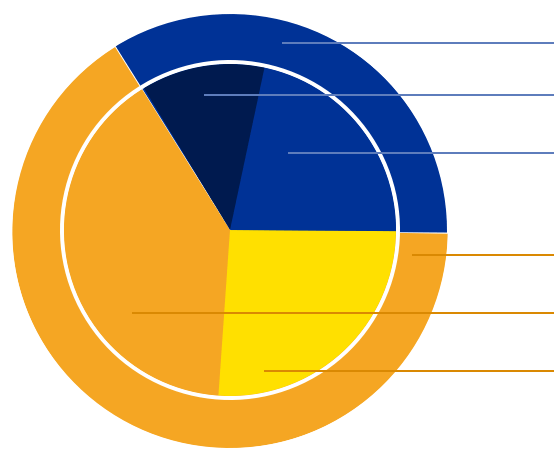

Flexible Procurement Programs: Complete vs. Component Overhead Cranes

- Transport Costs

- Cross Girder

- Other Parts

- Equipments Costs

- Cross Girder

- Other Parts

Complete plane

Component plane

Transport Cost Analysis

As shown in the Overhead Crane Costs Pie Chart (left), transport costs account for a significant portion of expenses, with the cross girder being the primary contributor. By addressing this cost driver, we offer two tailored solutions: Complete Crane and Component Crane packages.

Complete Overhead Crane Package

- Full System Delivery: Includes pre-assembled trolley, cross girder, end trucks, electrification systems, and all necessary components.

- Factory-Tested Reliability: Fully assembled and rigorously tested in our facility to ensure operational readiness.

- Easy Installation: Disassembled for shipping, then quickly reinstalled on-site with minimal effort.

- Best For: Clients prioritizing convenience, time savings, and hassle-free deployment.

Component Overhead Crane Package

- Exclusions: Cross girder (to be sourced locally by the client).

- Key Benefits:

- Reduced Transport Costs: Eliminate bulky cross girder shipping expenses.

- Local Flexibility: We provide detailed engineering drawings, 3D models, and step-by-step guidance for local cross girder fabrication.

- Best For: Cost-conscious clients with access to local steel resources or fabrication capabilities.